Adamantane derivative monomer, color photoresist and preparation method thereof, color filter

A technology of color photoresist and derivatives, which is applied in the field of photoresist, can solve the problems of color photoresist’s influence on transmittance and poor heat resistance, and achieve the effect of improving transmittance and enhancing heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

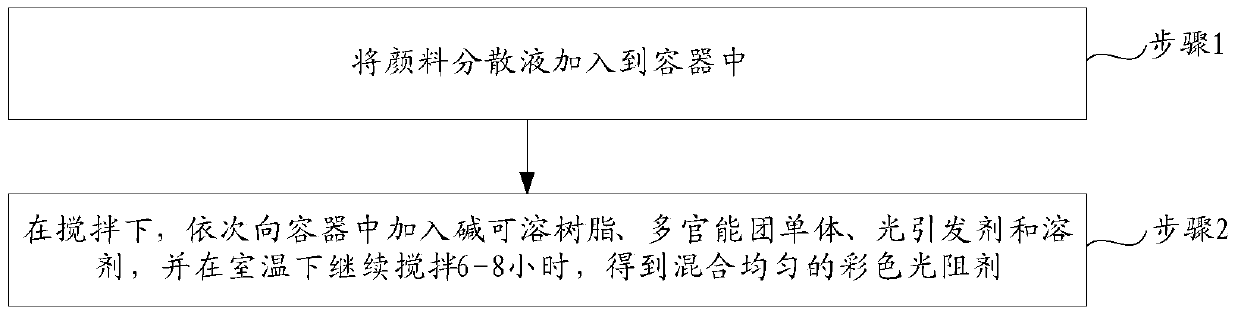

[0056] Such as figure 1 As shown, the embodiment of the present invention also provides a preparation method of a color photoresist, which adopts the color photoresist described in the above-mentioned embodiment, comprising the following steps:

[0057] Step 1: Add the pigment dispersion into the container;

[0058] In this step, the pigment dispersion liquid to be used is firstly added into the container, wherein the added pigment dispersion liquid may be one or more pigment dispersion liquids to be used. It can be understood that the amount of pigment dispersion liquid required in each color photoresist is different. Therefore, those skilled in the art can select an appropriate weight portion of pigment dispersion liquid within the above range according to the requirements of the process.

[0059] Step 2: Under stirring, add alkali-soluble resin, multifunctional monomer, photoinitiator and solvent to the container in sequence, and continue stirring at room temperature for 6...

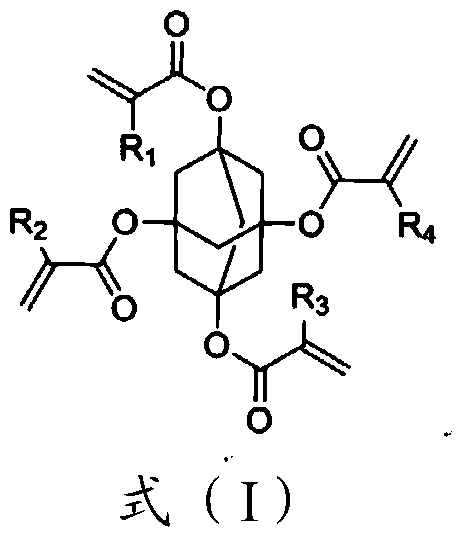

Embodiment 1

[0066] In parts by weight, first add 30 parts of red pigment dispersion into the bottle, and then add 10 parts of alkali-soluble resin, 1 part of dipentaerythritol pentahexaacrylate monomer, 4 parts of 1,3 , 5,7-tetra(acrylate) adamantane, 1 part of photoinitiator, 1 part of additive, 53 parts of solvent, and continue to stir at room temperature at 80r / min for 6 hours to prepare a red photoresist.

Embodiment 2

[0070] In parts by weight, first add 15 parts of green pigment dispersion and 10 parts of yellow pigment dispersion into the bottle, and then add 12 parts of alkali-soluble resin, 1 part of dipentaerythritol pentahexaacrylic acid under stirring at 120r / min Monomer, 4 parts of 1,3,5,7-tetra(acrylate) adamantane, 1 part of photoinitiator, 1 part of additive, 56 parts of solvent, and continue stirring at room temperature at 120r / min for 7 hours to prepare a green Photoresist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com