Reflective mechanical long-period fiber grating bandpass filter

A band-pass filter and fiber grating technology, applied in light guides, optics, instruments, etc., can solve the problems of non-adjustable filtering characteristics and single function, and achieve the effect of convenient filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

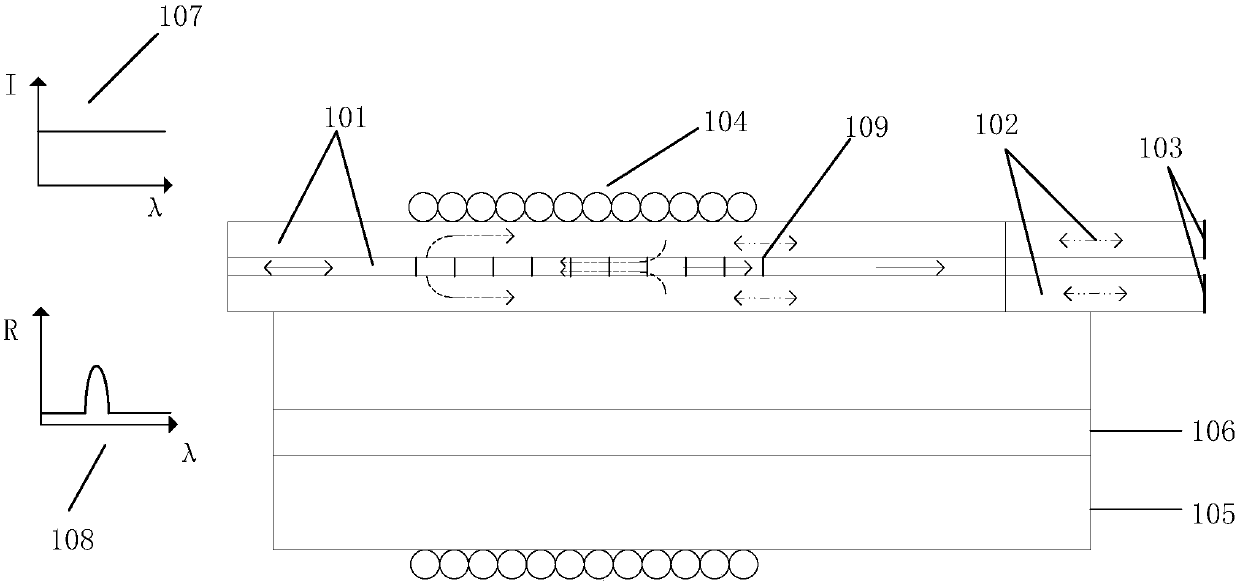

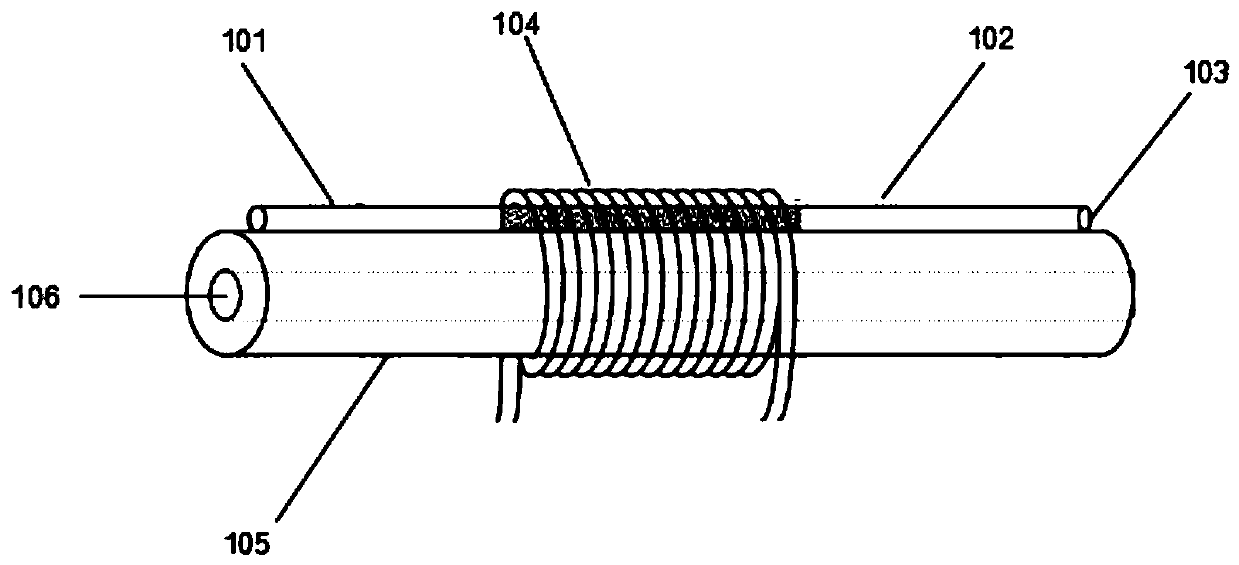

[0018] refer to figure 1 , a reflective mechanical long-period fiber grating bandpass filter, including a cored fiber 101, a hollow core fiber 102, an end reflector 103, a winding wire 104, a thermally conductive cylindrical sleeve 105 and a heating rod 106, and a cored fiber 101 Placed on the heat-conducting cylindrical sleeve 105, the heating rod 106 is placed inside the heat-conducting cylindrical sleeve 105, the cored optical fiber 101 and the thermally-conducting cylindrical sleeve 105 are wound together by the winding wire 104, and the hollow-core optical fiber 102 and the cored optical fiber 101 are fused together , an end reflector 103 is provided at the end face of the output end of the hollow-core optical fiber 102 .

[0019] Furthermore, the winding wire 104 is a material with a large coefficient of thermal expansion and good elasticity. Still further, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com