A kind of fabrication method of mechanical long-period fiber grating

A technology of fiber grating and manufacturing method, which is applied in the direction of cladding optical fiber, grating fiber, optical waveguide and light guide, etc., can solve the problems of complex and high manufacturing cost of long-period fiber grating, achieve convenient filtering effect, save cost, and obtain materials easily Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

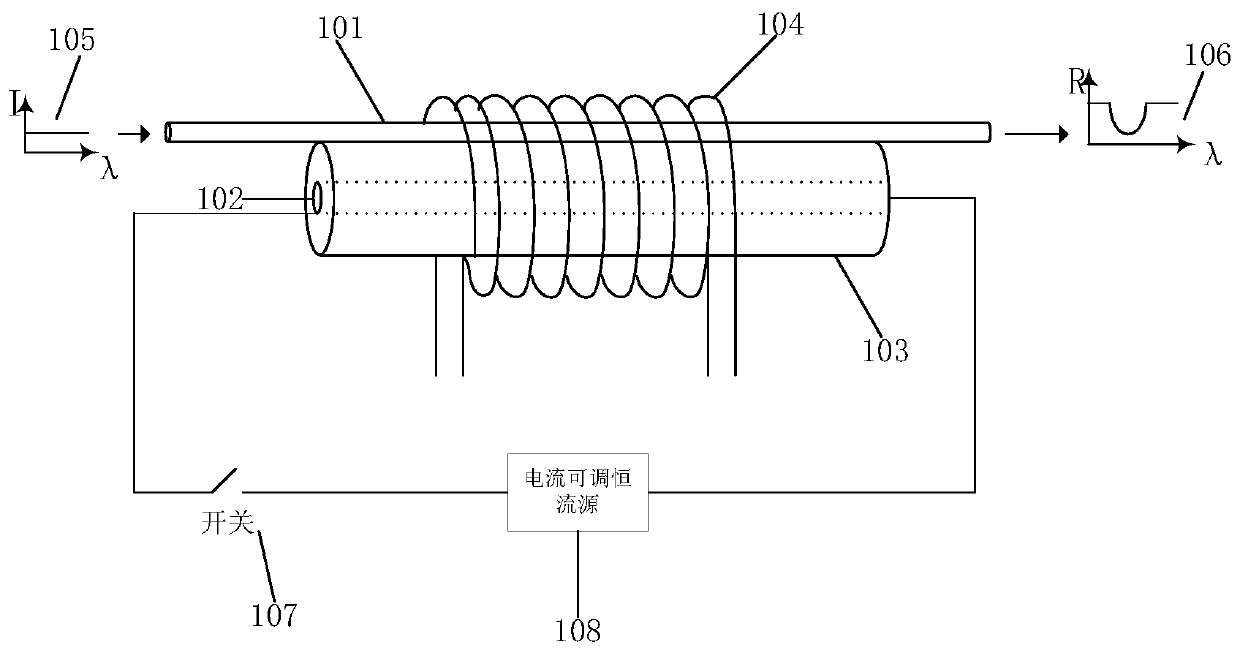

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] refer to Figure 1-Figure 3 , a method for manufacturing a mechanical long-period fiber grating, comprising the following steps:

[0027] 1) if figure 1 , prepare an optical fiber 101 . The optical fiber selected in the present invention includes but not limited to single-mode optical fiber.

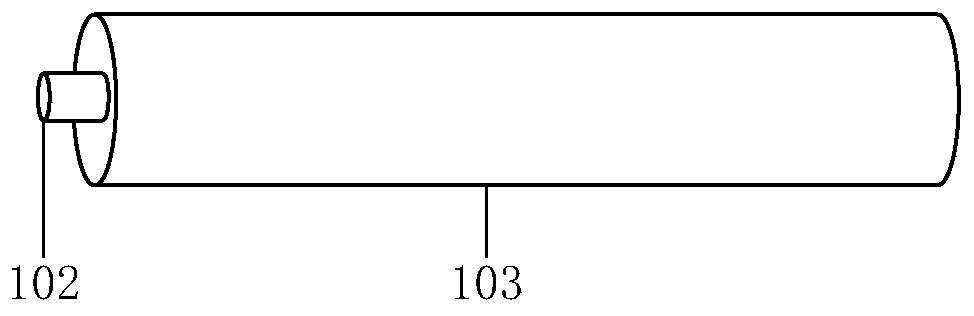

[0028] 2) if figure 2 , prepare the heating rod 102 and the heat conduction cylindrical sleeve 103, wherein the heating rod 102 adopts electric heating method, the material of the heating rod 102 includes but not limited to stainless steel; the center of the heat conduction cylindrical sleeve 103 is empty, and the heating rod 102 can be put into it and in close contact. The heat conducting cylindrical sleeve 103 is made of a material with a large coefficient of thermal expansion, including but not limited to aluminum.

[0029] 3) if image 3 , put the optical fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com