A centrifuge scraper mechanism

A centrifuge and scraper technology, which is applied in the field of centrifuges, can solve problems such as time-consuming and labor-intensive removal of potential safety hazards, and achieve the effect of avoiding potential safety hazards and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] For ease of understanding, the present invention will be described in detail below in conjunction with the accompanying drawings.

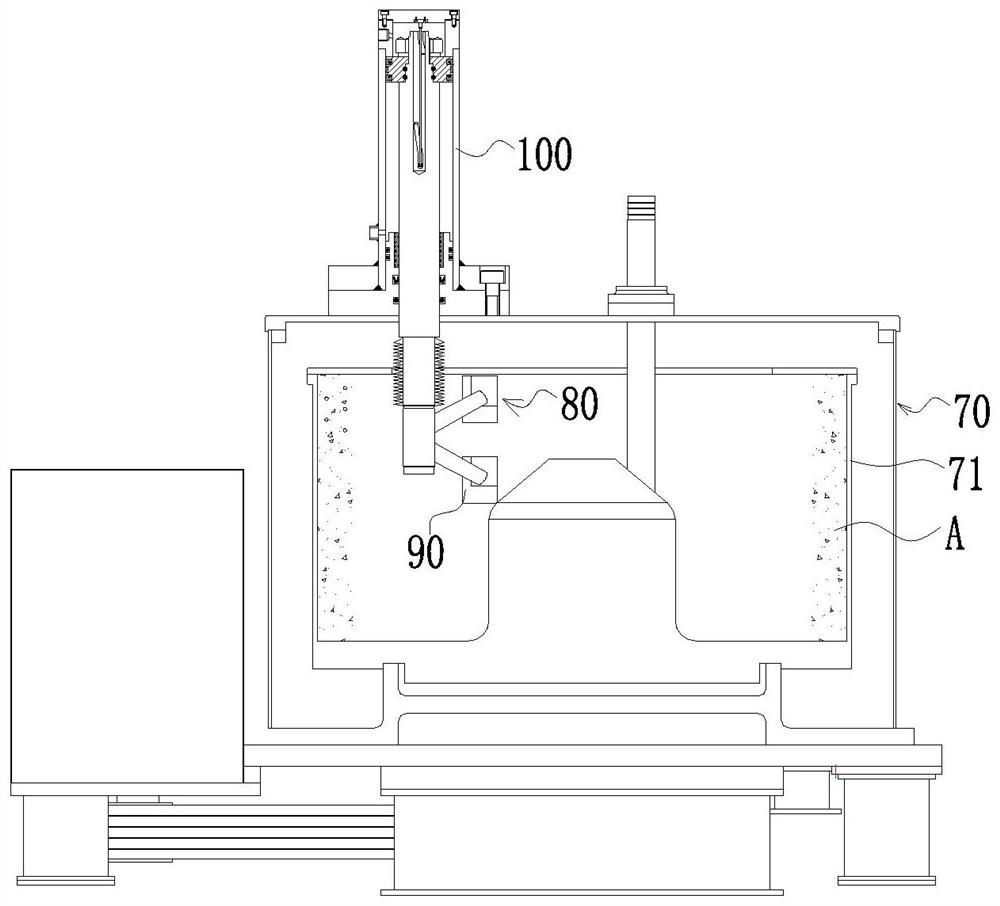

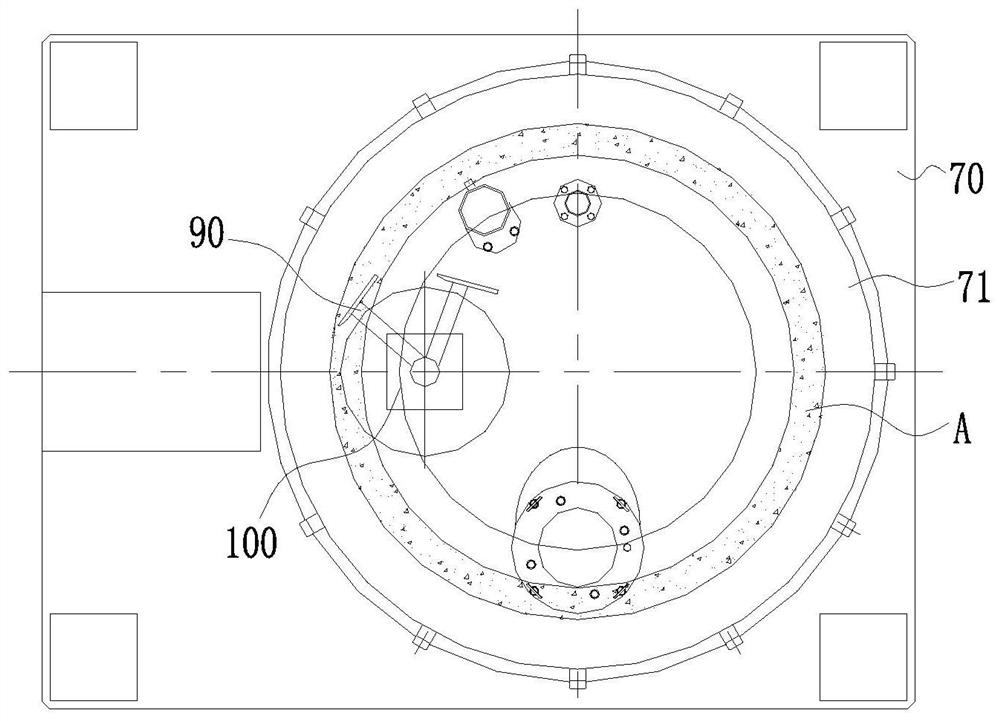

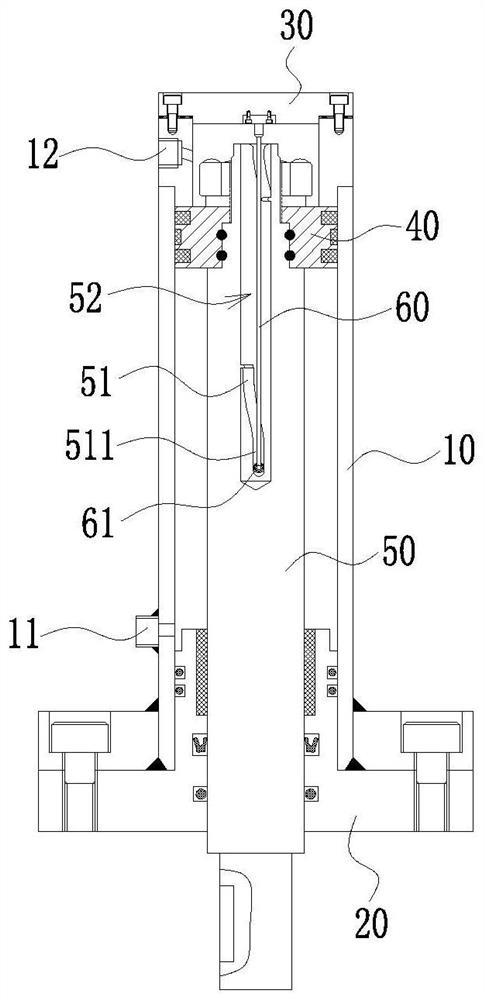

[0025] A centrifuge scraper mechanism, including a scraper device 80 arranged on the centrifuge 70 for scraping the filter cake A on the inner wall of the drum 71, the scraper device 80 includes a scraper 90 and a driving device 100 for driving the scraper 90, and the scraper 90 is adjacent to On the inner wall of the drum 71, the driving device 100 drives the scraper 90 to rotate from the initial position and cut into the position of the filter cake A in the drum 71 and continue to make a linear motion to scrape the filter cake A until it reaches the bottom of the drum 71, and the scraper 90 completes the scraping action Afterwards, the driving device 100 drives the scraper 90 to linearly retreat from the bottom of the drum 71 to the top and rotate to an initial position away from the drum 71 . After the centrifuge 70 completes the centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com