Train brake mounted at bottom of train

A technology for brakes and trains, applied in the direction of brakes, brake components, vehicle components, etc., can solve the problems of large demand for sand and hidden safety hazards, and achieve the effect of strengthening braking effect, improving safety and reducing demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

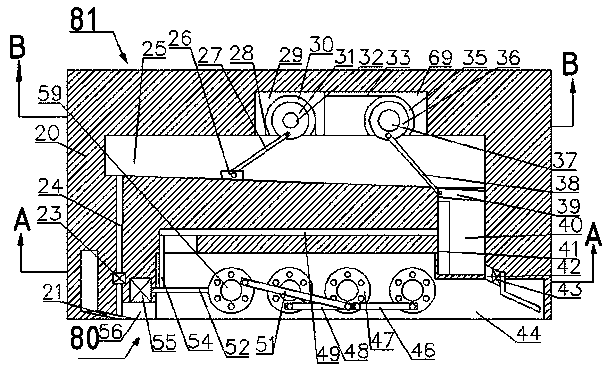

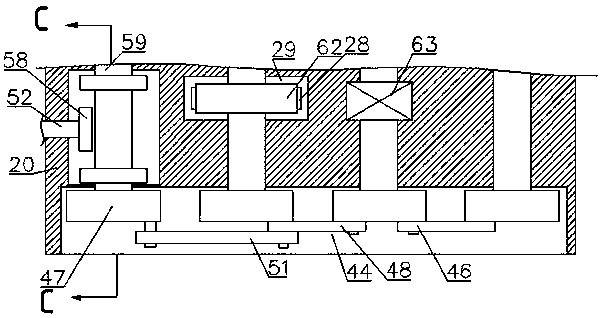

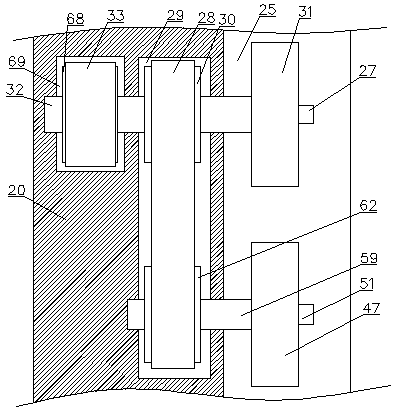

[0017] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The front, back, left, right, up, and down directions of the view direction are the same, figure 1 It is the front view of the device of the present invention, figure 1 The directions shown are consistent with the front, back, left, right, up, and down directions of the front view direction of the device of the present invention.

[0018] refer to Figure 1-4 According to an embodiment of the present invention, a train brake installed at the bottom of a train includes a vehicle body 20, and a wheel space 44 with an opening downward is arranged symmetrically front and rear in the vehicle body 20, and the wheel space 44 is provided with a friction active brake. A friction member 80 for shaft braking, the friction member 80 includes four wheel axles 59 rotatably mounted between the front wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com