Agricultural seed water separation device

A water separation and seed technology, applied in the direction of filtration separation, solid separation, wet separation, etc., can solve the problems of unfulfilled seeds, complex structure, poor water separation effect, etc., to achieve easy replacement, enhanced effect, The effect of avoiding water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

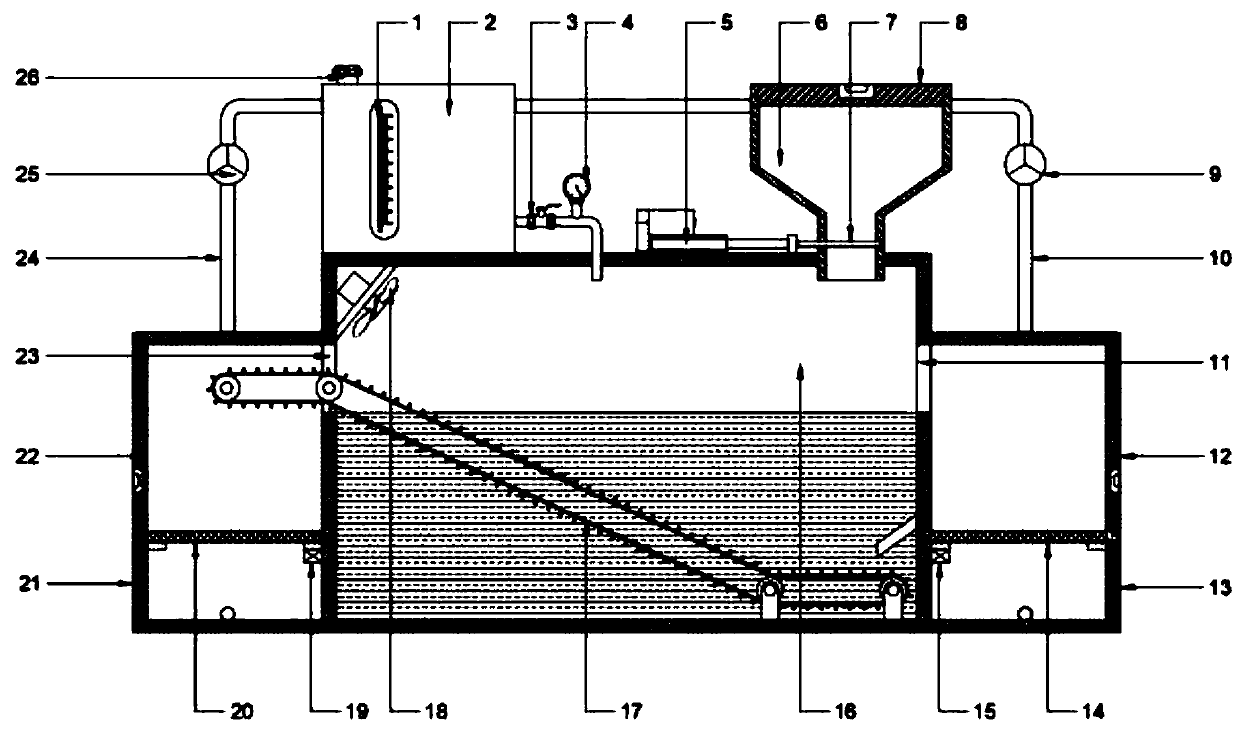

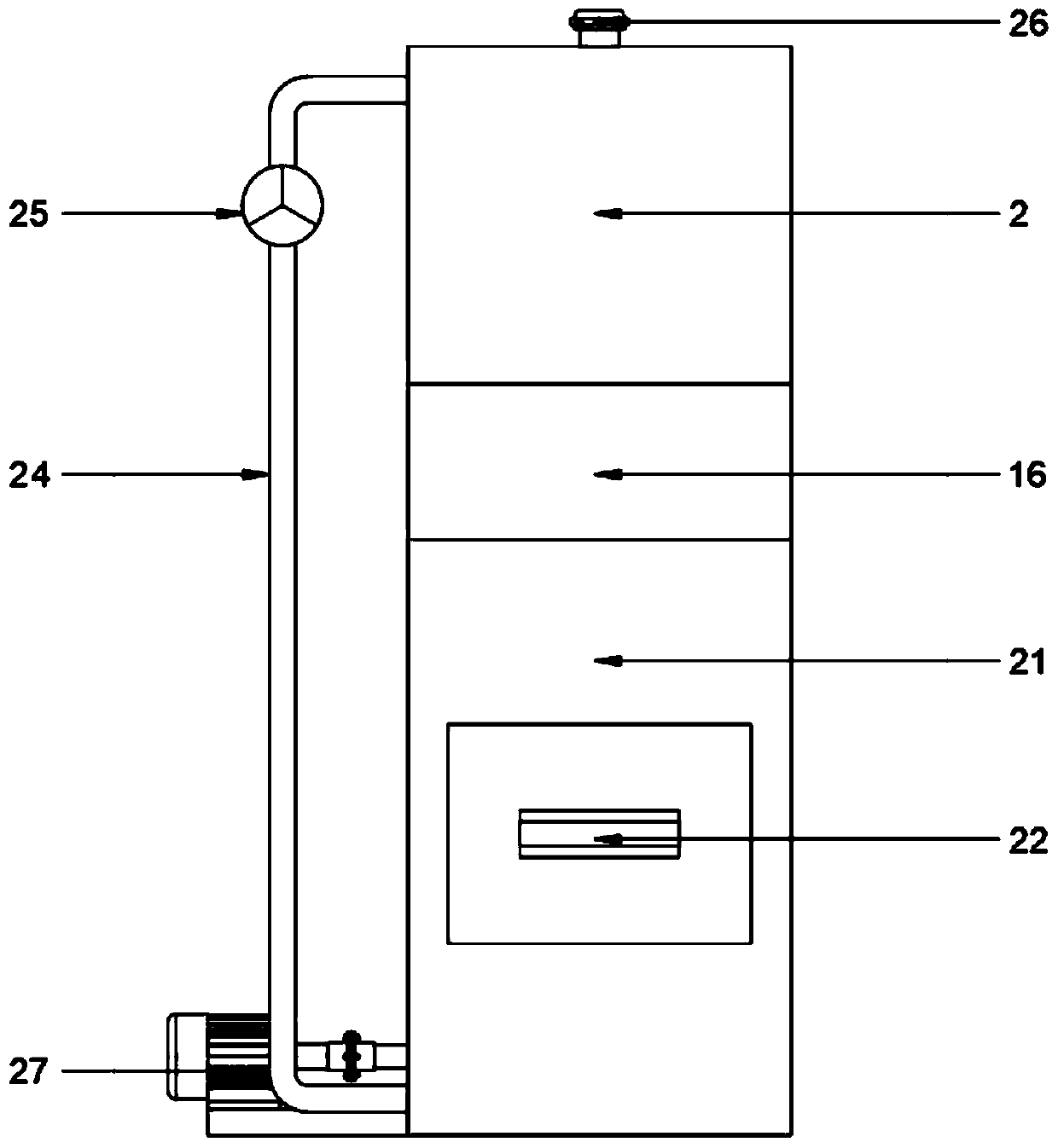

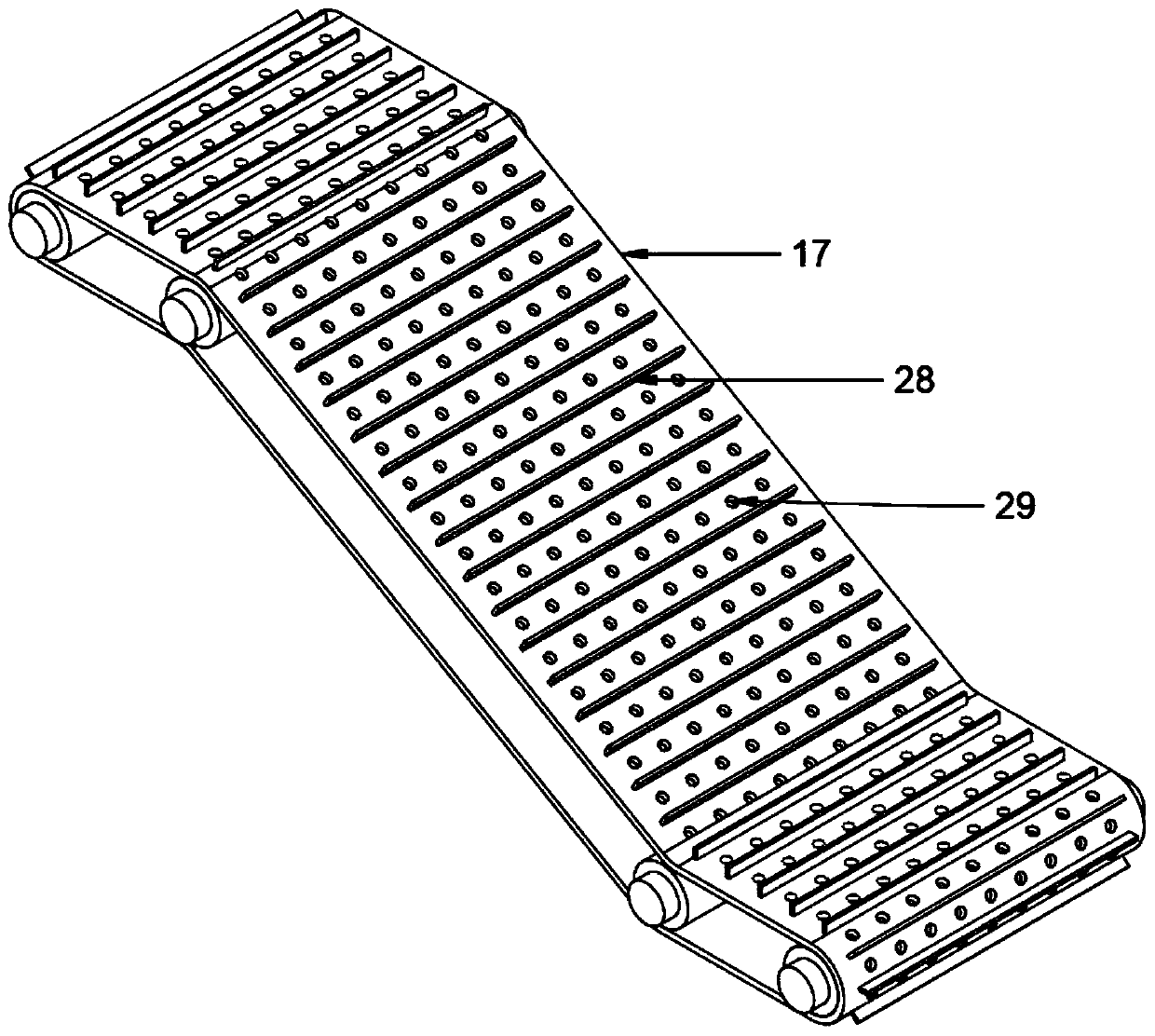

Embodiment 1

[0021] see Figure 1~3 , in the embodiment of the present invention, a kind of water separation device for agricultural seeds comprises a water separation box 16 and a conveyor belt 17, and above the water separation box 16, a water storage tank 2 and a feedstock tank 2 respectively connected to the water separation box 16 are arranged side by side. Assemblies, the first collection box 13 and the second collection box 21 are connected to each other on both sides of the water selection box 16, and the conveyor belt 17 is fixed inside the water selection box 16 and its feed end is above the feeding assembly position. Correspondingly, the discharge end of the conveyor belt 17 extends into the second collection box 21 from the second outlet 23 provided on one side of the water separation box 16, and the side of the water separation box 16 away from the second discharge gate 22 is also The first outlet 11 is provided and communicated with the first collection box 13, and the convey...

Embodiment 2

[0028] see image 3 , in the embodiment of the present invention, an agricultural seed water separation device, in order to improve the efficiency of water separation seeds of the device, quickly separate dry seeds and plump seeds, on the basis of embodiment 1, the inside of the water separation box 16 A fan 18 is arranged at a corner far away from the first outlet 11, and the shriveled seeds floating on the surface of the water are blown to the first outlet 11 to make it output from the first outlet 11, so as to prevent the impact on full seeds and enhance the seed water separation effect.

[0029] The working principle of the present invention is:

[0030]During work, open feed door 8, put seed into feed hopper 6 inside; Open valve 3, described water storage tank 2 injects water in water selection box 16 through outlet pipe, keeps water surface and first outlet 11 and second outlet 11. The exit height of the discharge door 22 is even; start the electric push rod 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com