Rotor for a rotary press

A rotary and rotor technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of product loss, damage efficiency, etc., and achieve the effect of improving efficiency, simple structure, and reducing the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Unless otherwise stated, the same reference numerals in the figures denote the same objects.

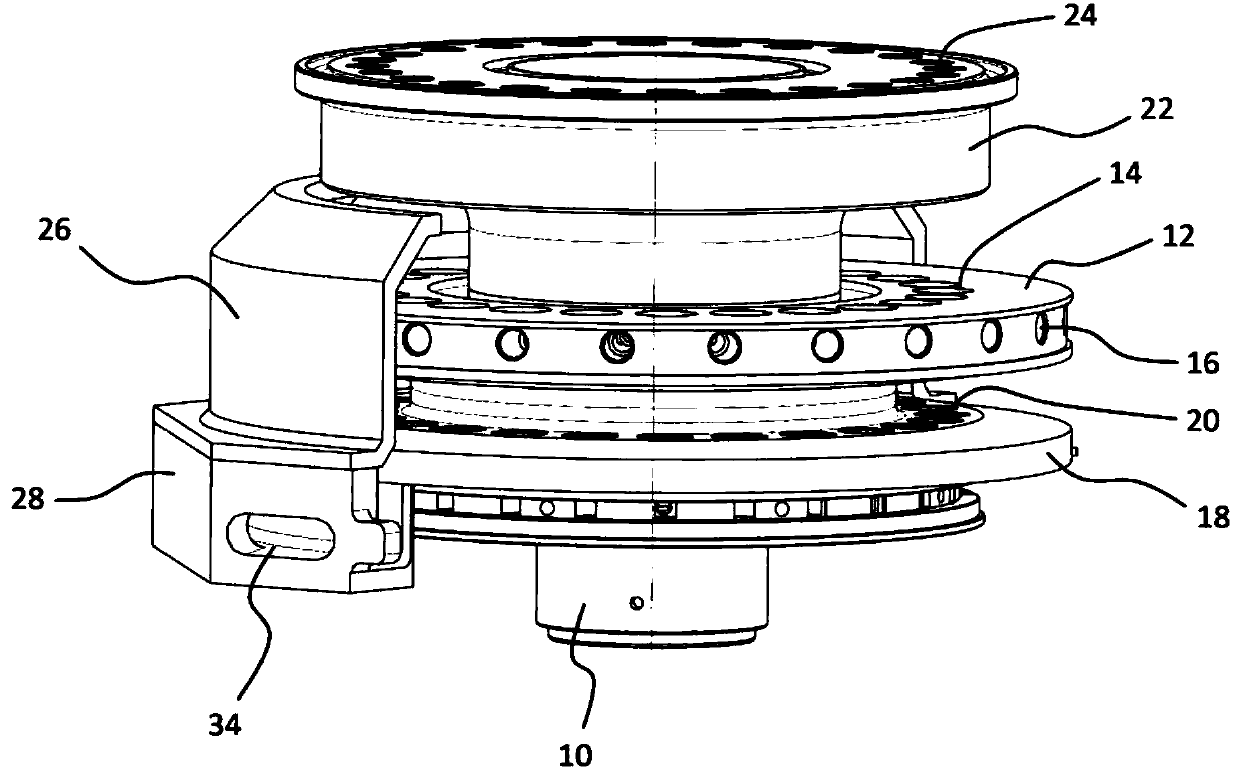

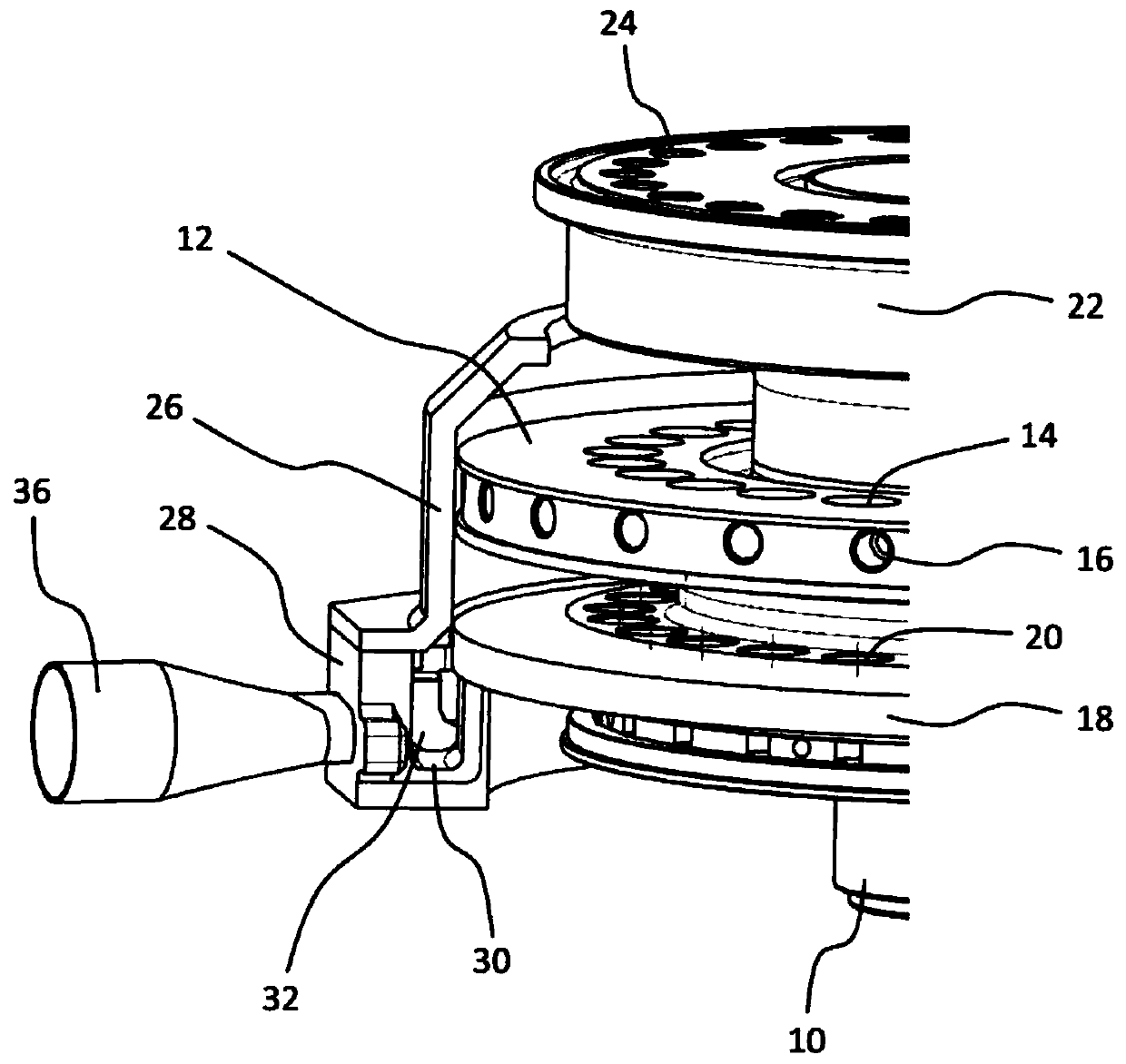

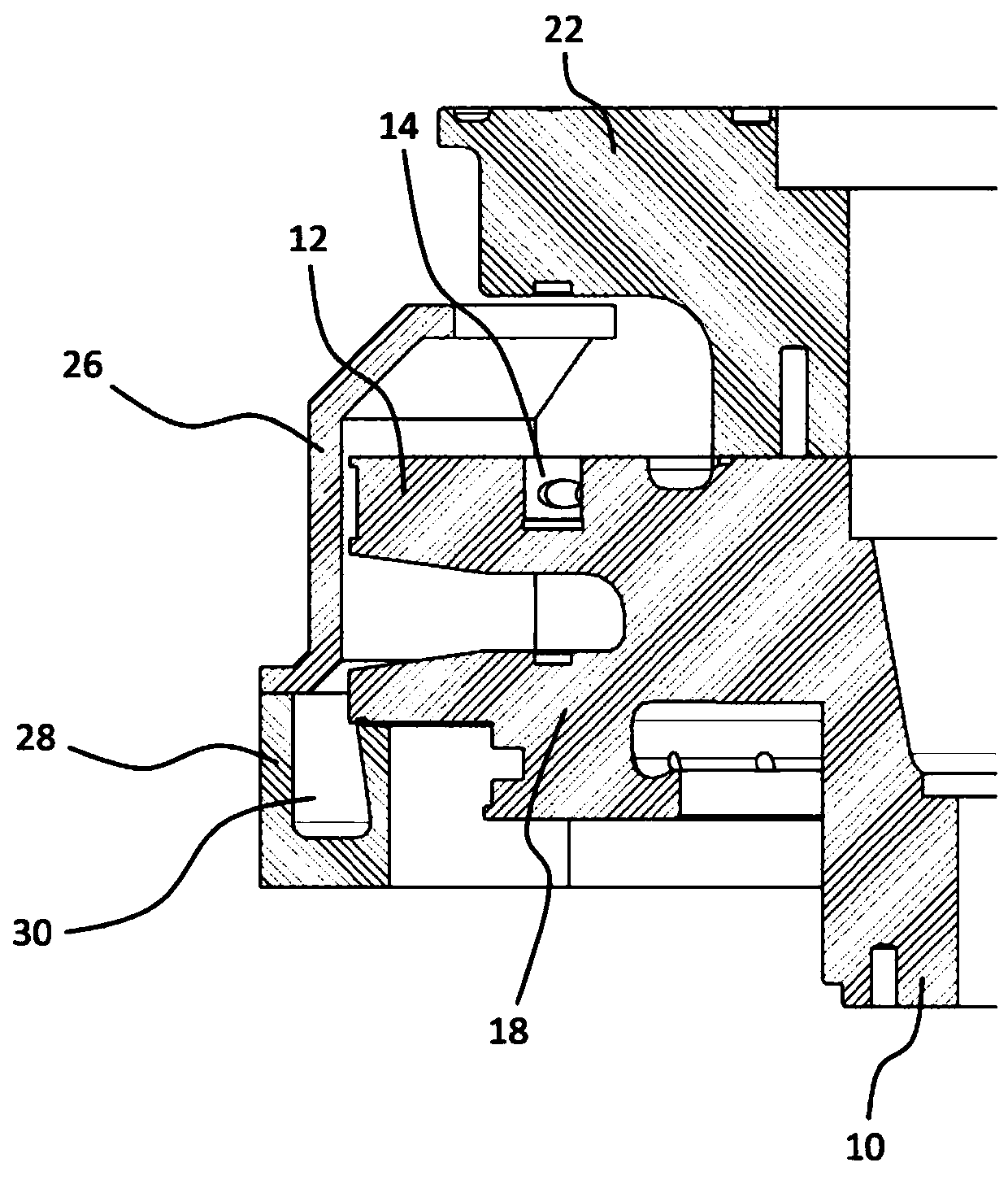

[0025]The rotor according to the invention shown in the figures is the rotor of a rotary press, in particular a rotary tablet press, for pressing eg powdery products into compacts, eg tablets. The rotor comprises a drive section 10 which is connected to a rotary drive for turning the rotor which is not shown in detail for reasons of simplicity. Die plate 12 is connected to drive section 10 . The die plate 12 has a plurality of sleeve receptacles 14 , in which die sleeves are inserted in the example, so that the die sleeves form the die holes of the die plate 12 . Also for reasons of simplicity, the die sleeve is not shown in the figures. The die plate 12 has a plurality of radial holes 16 on the peripheral side, into which locking screws for locking the die sleeve in the sleeve receptacle 14 can be inserted. This is known. In the example shown, the die disk 12 is designed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com