High-efficiency ultrasonic cleaning device and method

An ultrasonic cleaning and high-efficiency technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of low efficiency, poor cleaning effect, low utilization rate of sound energy, etc. Enhance the strength, enhance the effect, improve the efficiency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

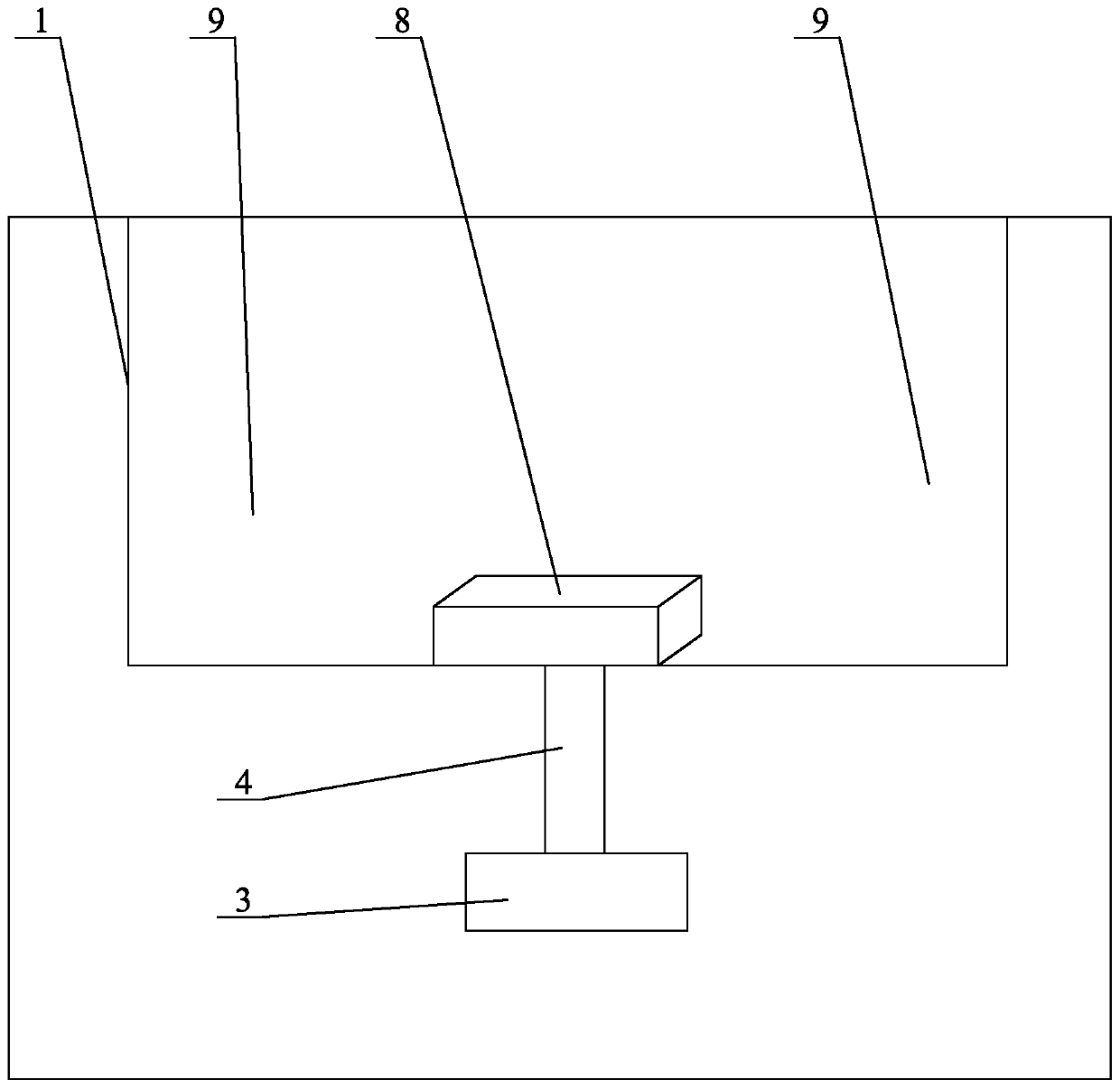

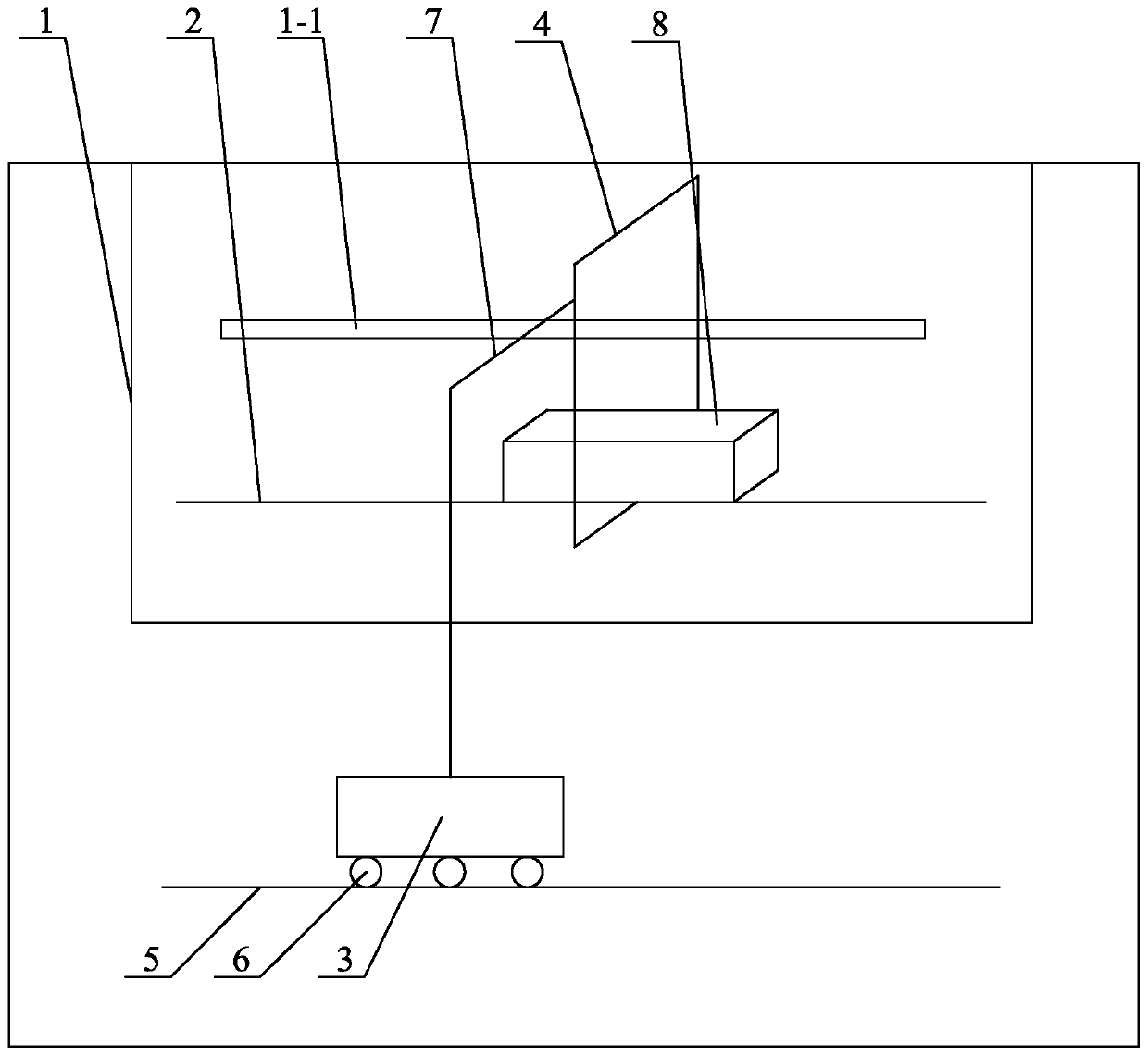

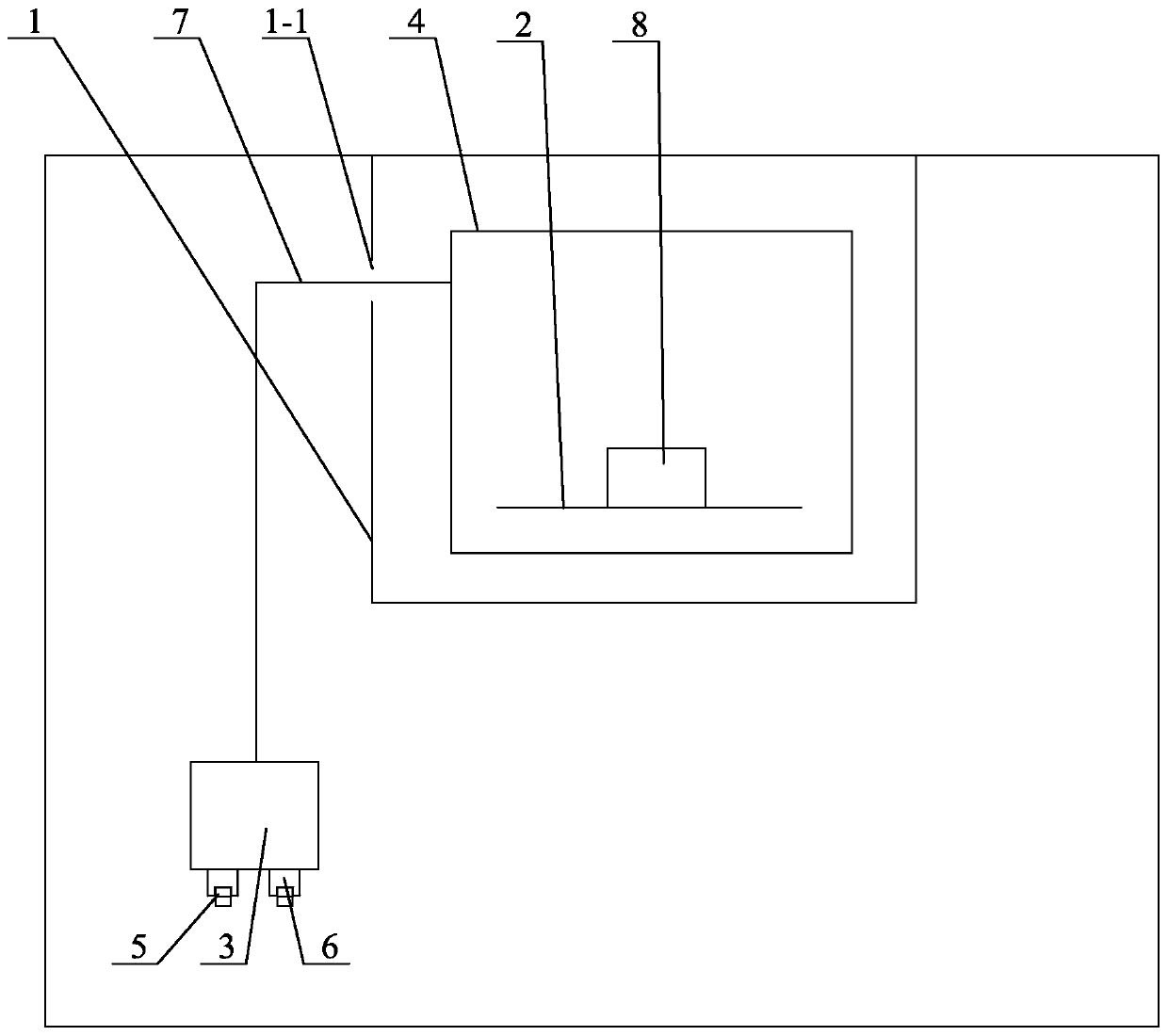

[0018] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a high-efficiency ultrasonic cleaning device described in this embodiment includes a cleaning tank 1, a sample placement table 2, an ultrasonic generator 3, an ultrasonic head 4 and a set of slide rails 5, and the sample placement table 2 is set in the cleaning tank 1, the ultrasonic generator 3 is arranged on the outside of the cleaning tank 1, the output end of the ultrasonic generator 3 is connected to the ultrasonic head 4, the shape of the ultrasonic head 4 is a frame, the ultrasonic head 4 is arranged in the cleaning tank 1 and is set in the sample Place the outside of platform 2, the bottom of sonotrode 3 is provided with a group of slide rails 5 along the length direction, and the lower end surface of sonotrode 3 is provided with a group of rollers 6, and rollers 6 and slide rail 5 are slidingly connected.

[0019] The invention proposes a method and device that can enhance...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 2 to Figure 4 To describe this embodiment, the ultrasonic head 4 in this embodiment is a square frame or a circular frame. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0024] In this embodiment, in order to facilitate the installation of the ultrasonic head 4 on the outside of the sample placement platform 2, the sample placement platform 2 can be fixed in the cleaning tank 1 using a cantilever type, that is, one side of the lower end of the sample placement platform 2 is fixedly connected to the cleaning tank 1 , the ultrasonic head 4 is set from the other side of the sample placement platform 2; the sample placement platform 2 can also be fixed in the cleaning tank 1 in a detachable assembled manner, and one side of the lower end of the sample placement platform 2 is fixedly connected to the cleaning tank 1 , and then the ultrasonic head 4 is set from the o...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination Figure 2 to Figure 4 Describe this embodiment, the sonotrode 3 described in this embodiment is arranged on the side below the cleaning tank 1, the end of the ultrasonic head 4 is connected with the output end of the sonotrode 3 through a strut 7, and the side wall of the cleaning tank 1 The upper part is provided with a through groove 1-1 along the length direction, and the pole 7 is inserted in the through groove 1-1. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment. Such design is to prevent the ultrasonic head 4 from interfering with the cleaning tank 1 during installation. The sonotrode 3 is arranged on the side below the cleaning tank 1 to prevent the sample 8 from interfering with the sonotrode 3 and its slide rail 5 when the sample 8 is installed, making it inconvenient to place and take out the sample 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com