Discharging sorting machine for noise-reducing casting blank production

A noise reduction type and sorting machine technology, which is applied in the field of casting blank machinery, can solve the problems of troublesome installation, harsh sound, disorder and disorder, etc., and achieve the effect of easy disassembly, avoid harsh sound, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

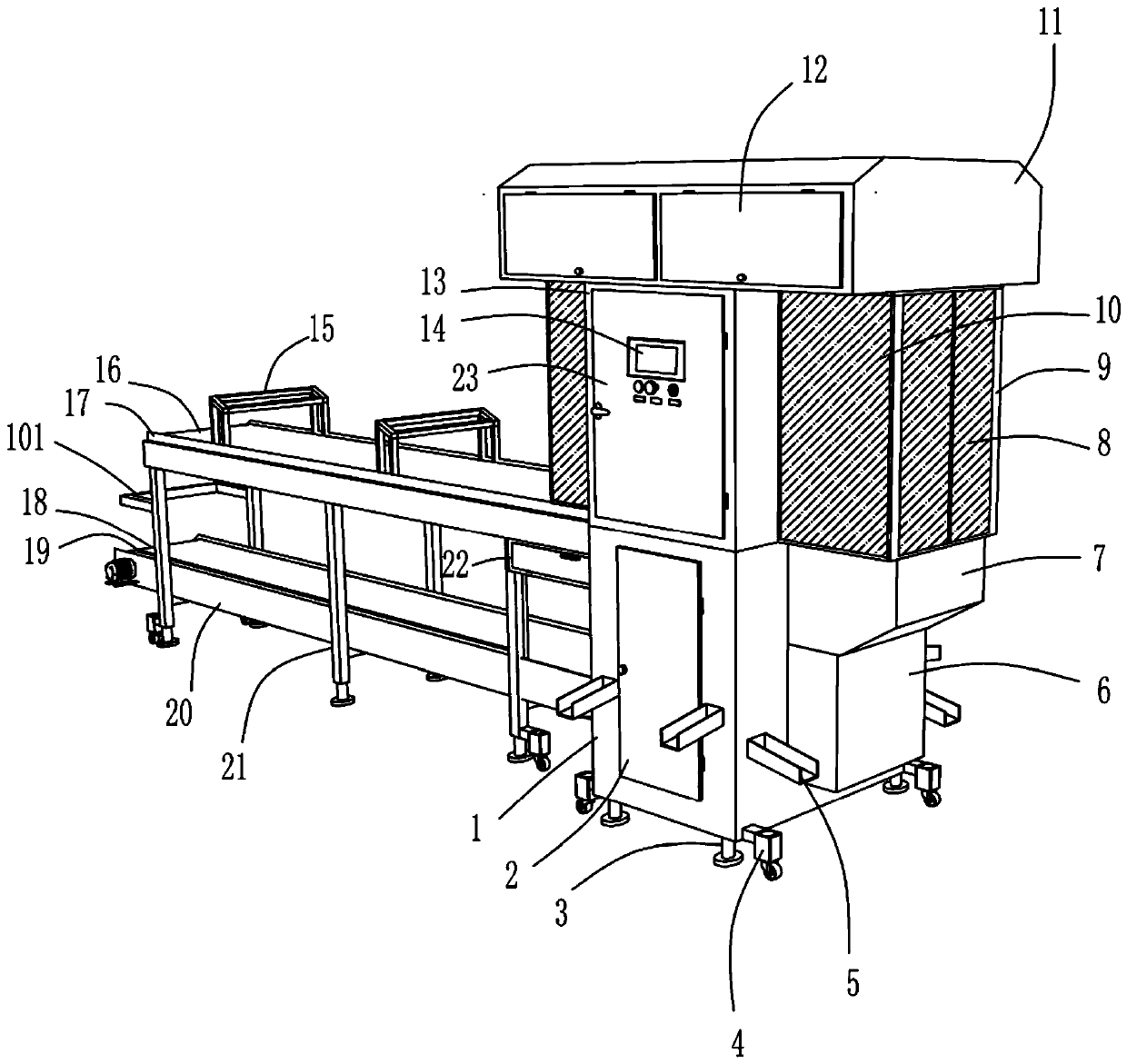

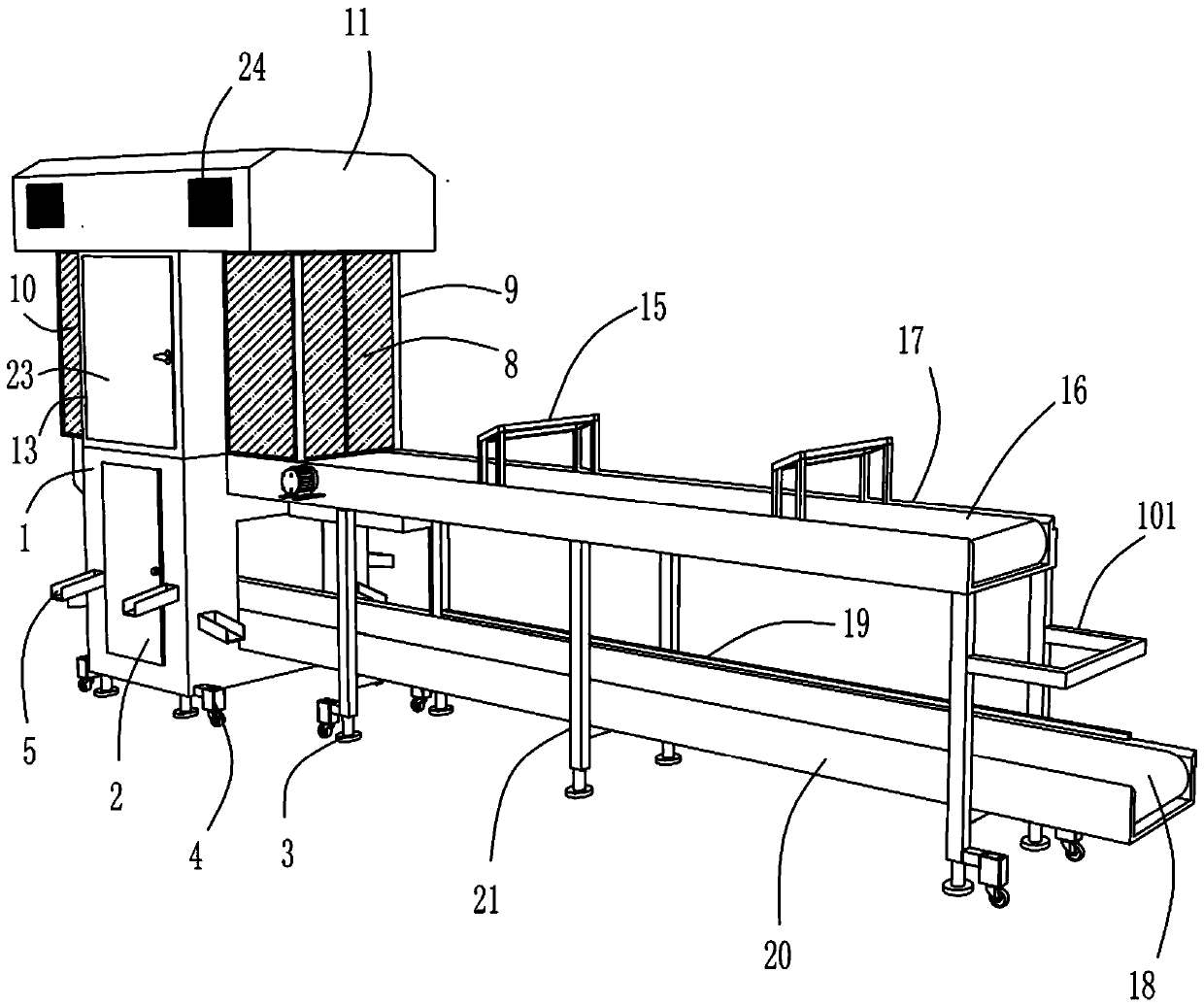

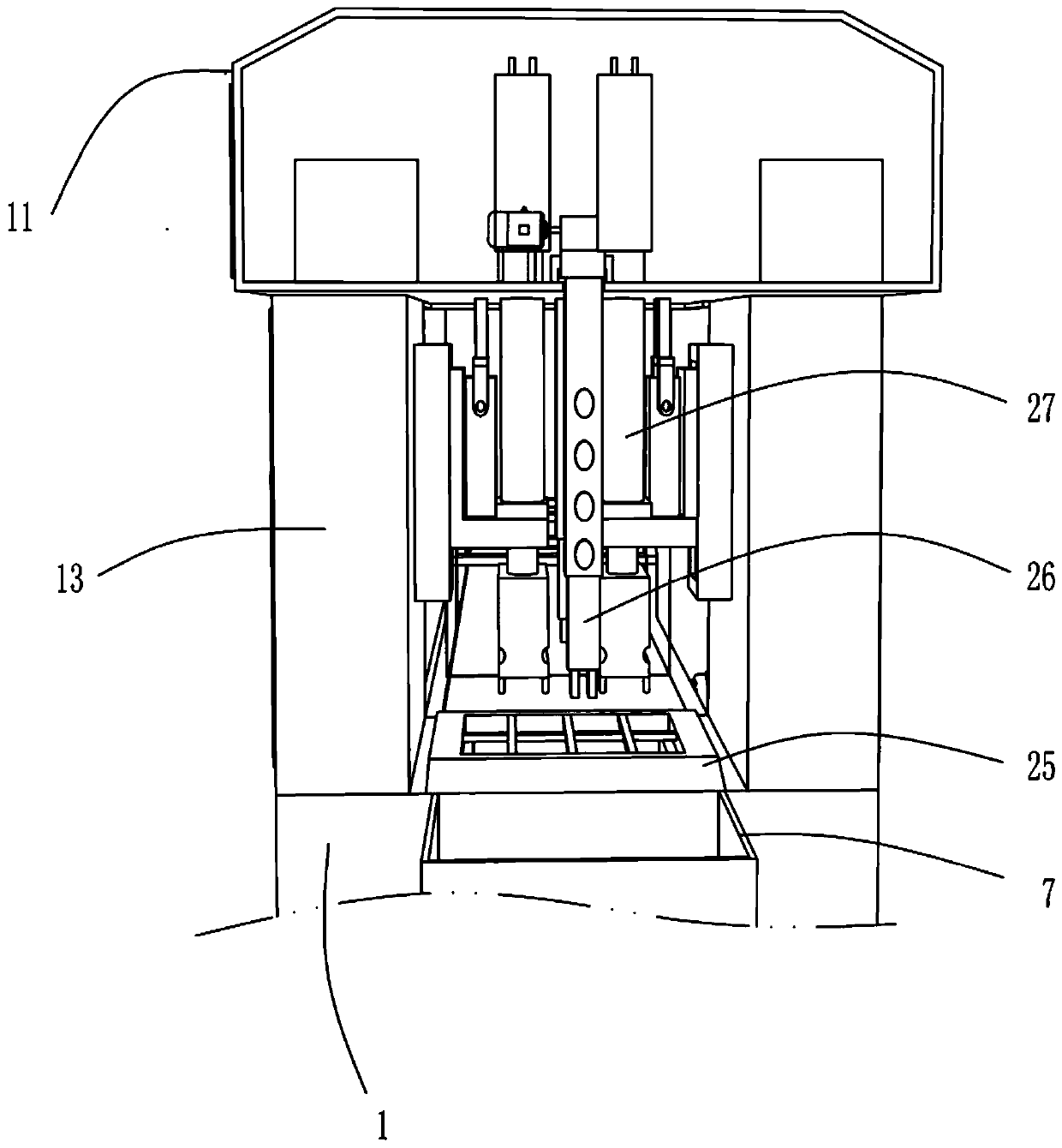

[0028] A noise-reducing unloading sorter for the production of casting blanks, such as Figure 1-6 As shown, it includes a discharge box 1, a first box door 2, a hopper 5, a lower hopper 7, a sliding window 8, a frame 9, a fixed window 10, an installation box 11, a second box door 12, and a first electric control box 13. Operation display screen 14, feeding conveying mechanism 16, first concave frame 17, waste conveying mechanism 18, second concave frame 20, H-shaped fixing frame 21, second electric control box 22, third box door 23 , radiating louvers 24, feeding porous frame 25, pick-up and unloading manipulator 26 and ultrasonic pick-up mechanism 27; the middle part of the discharge box 1 is provided with a hole 28, and both sides of the discharge box 1 are provided with installation grooves 29, and the discharge box 1 The side is hinged with a first box door 2 that is compatible with the installation groove 29, and the top of the discharge box 1 is fixedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com