Pipeline repairing method

A technology for pipelines and pipeline leaks, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems affecting construction period, loss, long cycle, etc., to achieve low repair cost, low social negative impact, The effect of short repair cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

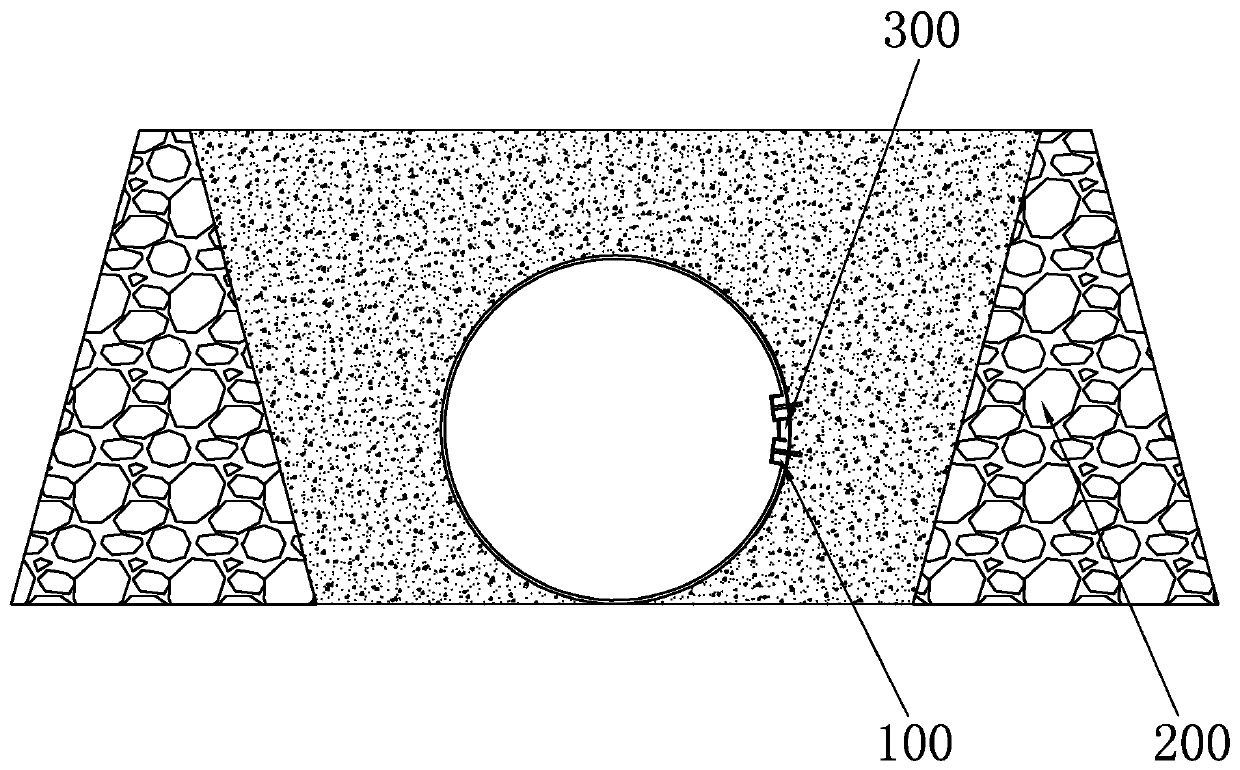

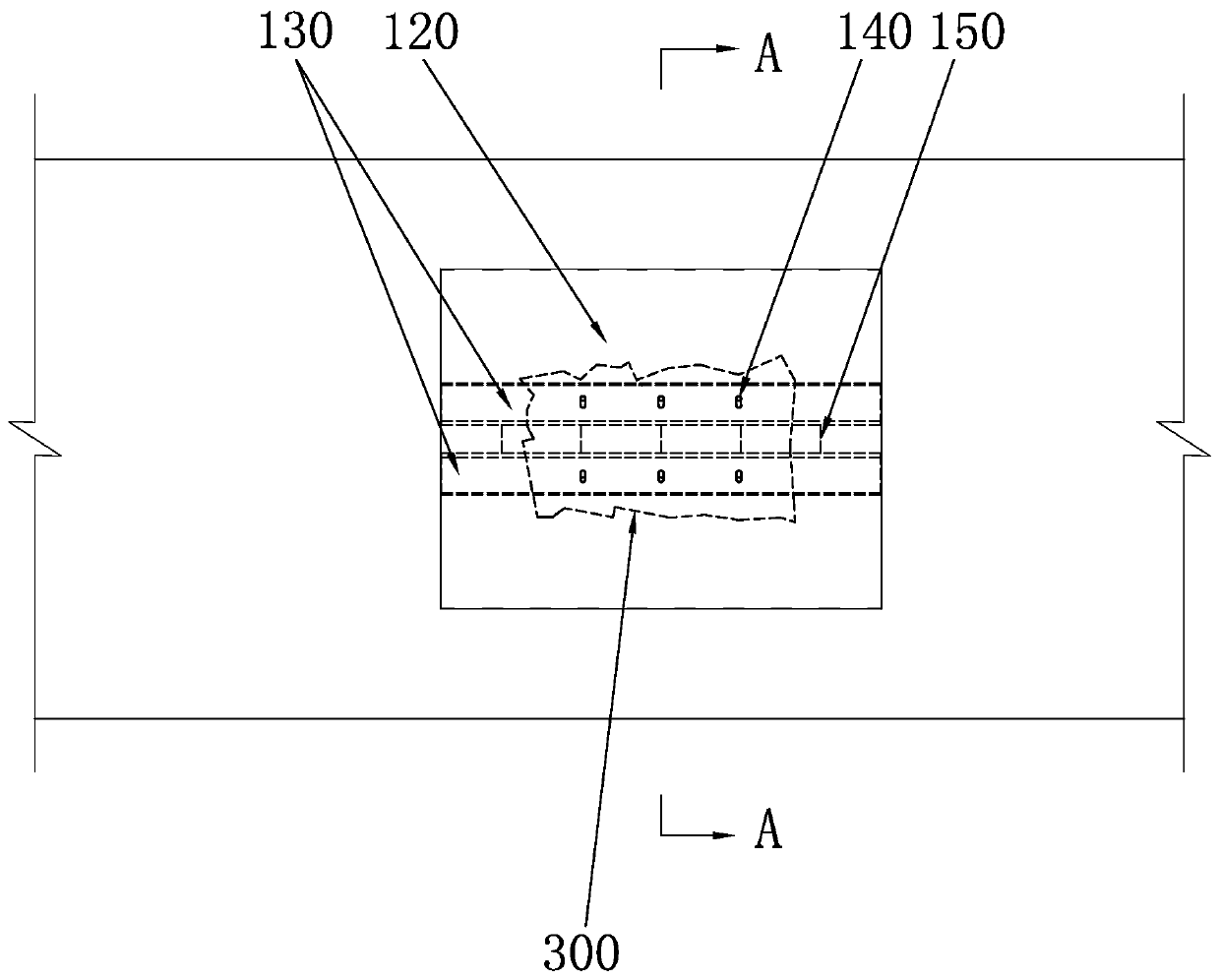

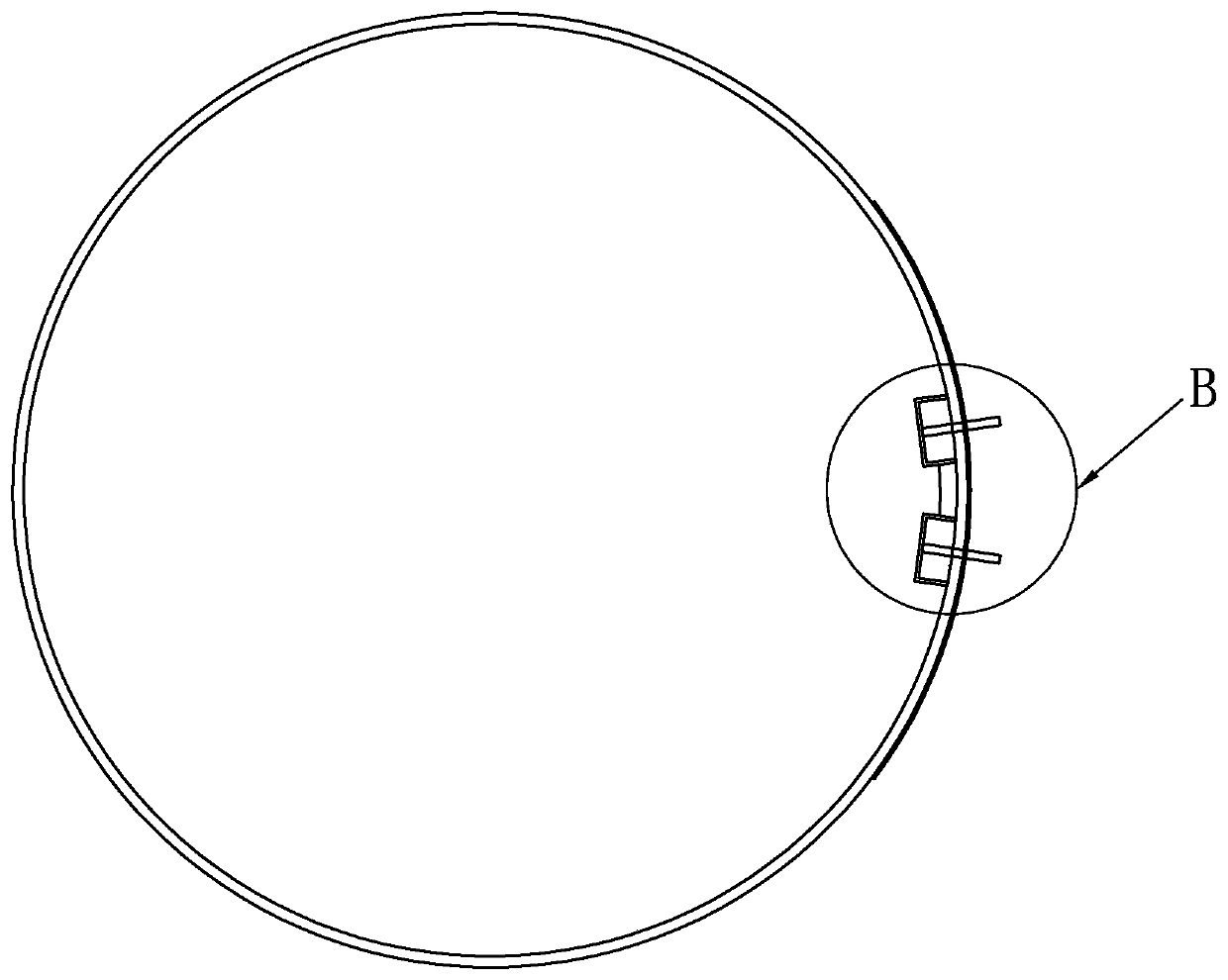

[0043] refer to Figure 1 to Figure 6 , the pipeline repair device 100 includes a leak blocking plate 120 and a fixing piece 130 . The leakage stopper 120 completely covers the leakage point 300 of the pipeline. Specifically, the leak stopper 120 has an area greater than that of the pipeline leak 300, the leak stopper 120 completely covers the pipeline leak 300, and the leak stopper 120 prevents the water in the pipeline from continuing to leak. flow out. At the same time, refer to figure 2 and image 3 , the arc of the leak-stopping plate 120 is the same as the arc of the pipe, where the arc of the pipe refers to the arc of the radial cross section of the pipe. In this embodiment, the pipe is a round pipe, so the cross-section of the leakage plugging plate 120 is arc-shaped. Preferably, the leak plugging plate 120 is a steel leak plugging plate. The fixing member 130 is erected on the pipeline leakage point 300 . Specifically, the fixing piece 130 is pressed against t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com