Progressive guide pipe

A guide tube and progressive technology, applied in the field of wall-mounted solar collectors, can solve the problems of easy breakage, complicated process, scrapped all-glass collector cores, etc., and achieve the effect of avoiding fragility and increasing the deformation coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

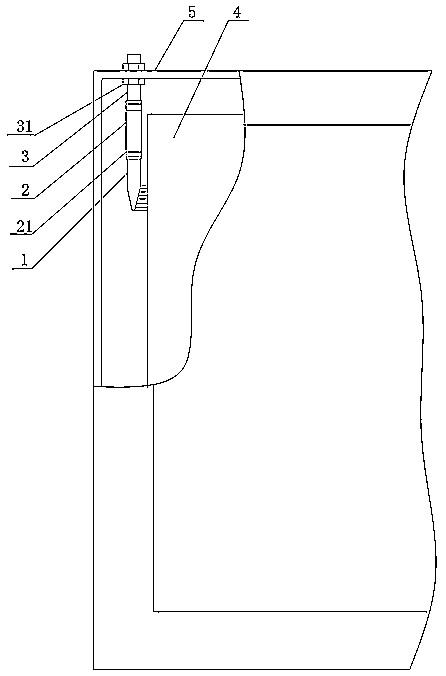

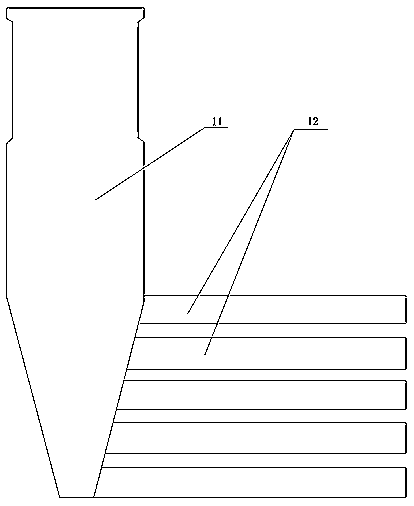

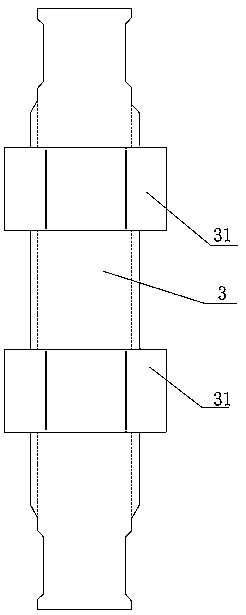

[0018] Such as figure 1 As shown, the progressive guide tube of this embodiment is composed of a collecting tube 1, a buffer tube 2, and a positioning tube 3, and is characterized in that: the sub-tube 12 of the collecting tube 1 is embedded in the sandwich cavity of the all-glass heat collecting core 4 Inside, the mother pipe 11 is connected to the buffer pipe 2; the other end of the buffer pipe 2 is connected to the positioning pipe 3, and the positioning pipe 3 leads out to the frame body 5 of the heat-absorbing medium all-glass solar collector plate, and the positioning pipe 3 is fixed on the frame body 5 . The buffer tube 2 is made of high-temperature-resistant plastic material, which has the effect of buffering deformation. Pipeline fastening clips 21 are fixed at the joints of the buffer pipe 2 and the gathering pipe 1 and the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com