Workpiece detection device

A detection device and workpiece technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem of not having screw, not having nut fixing, not having, etc., to improve the pass rate and improve the detection data. Accuracy, better data, more accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

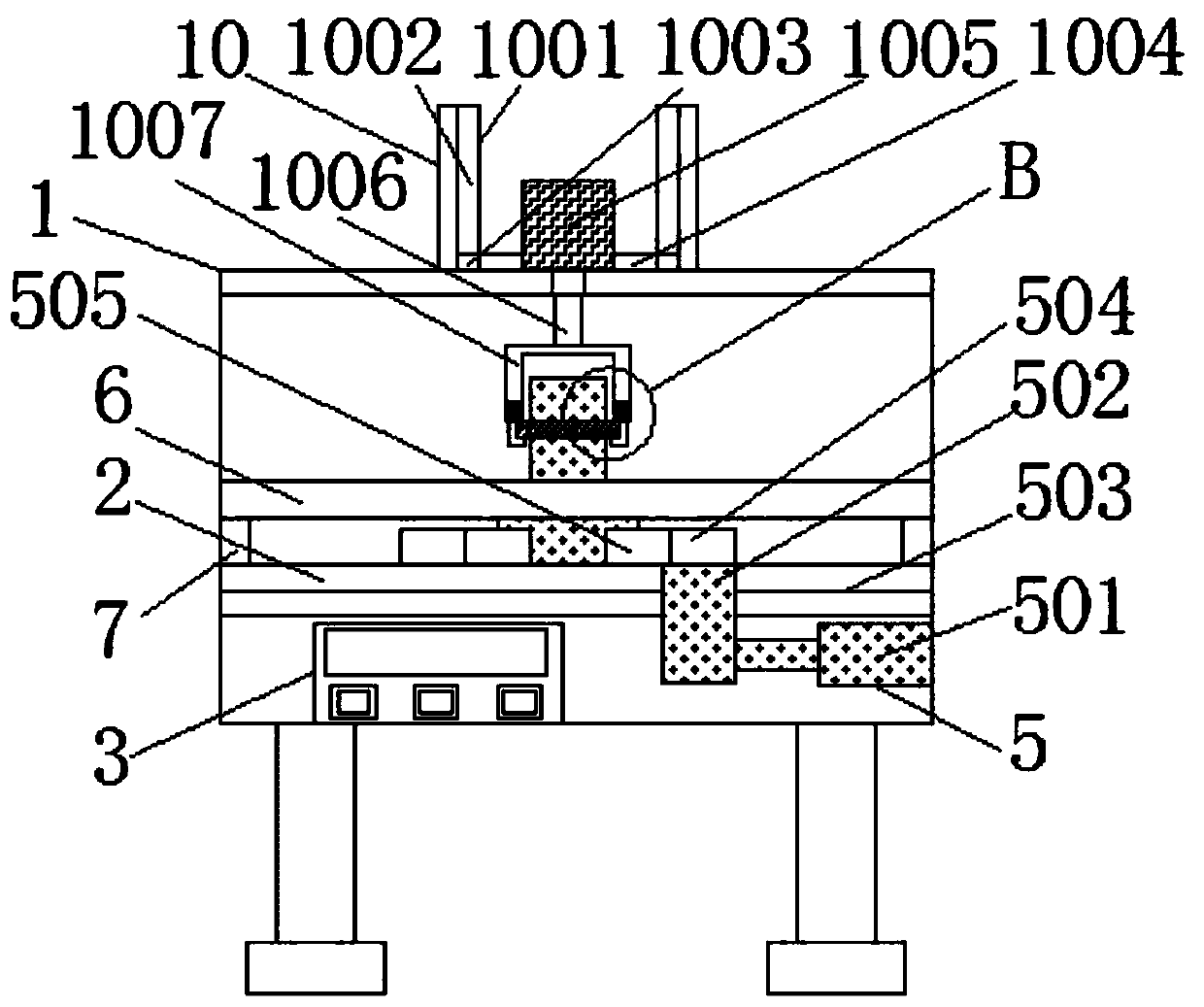

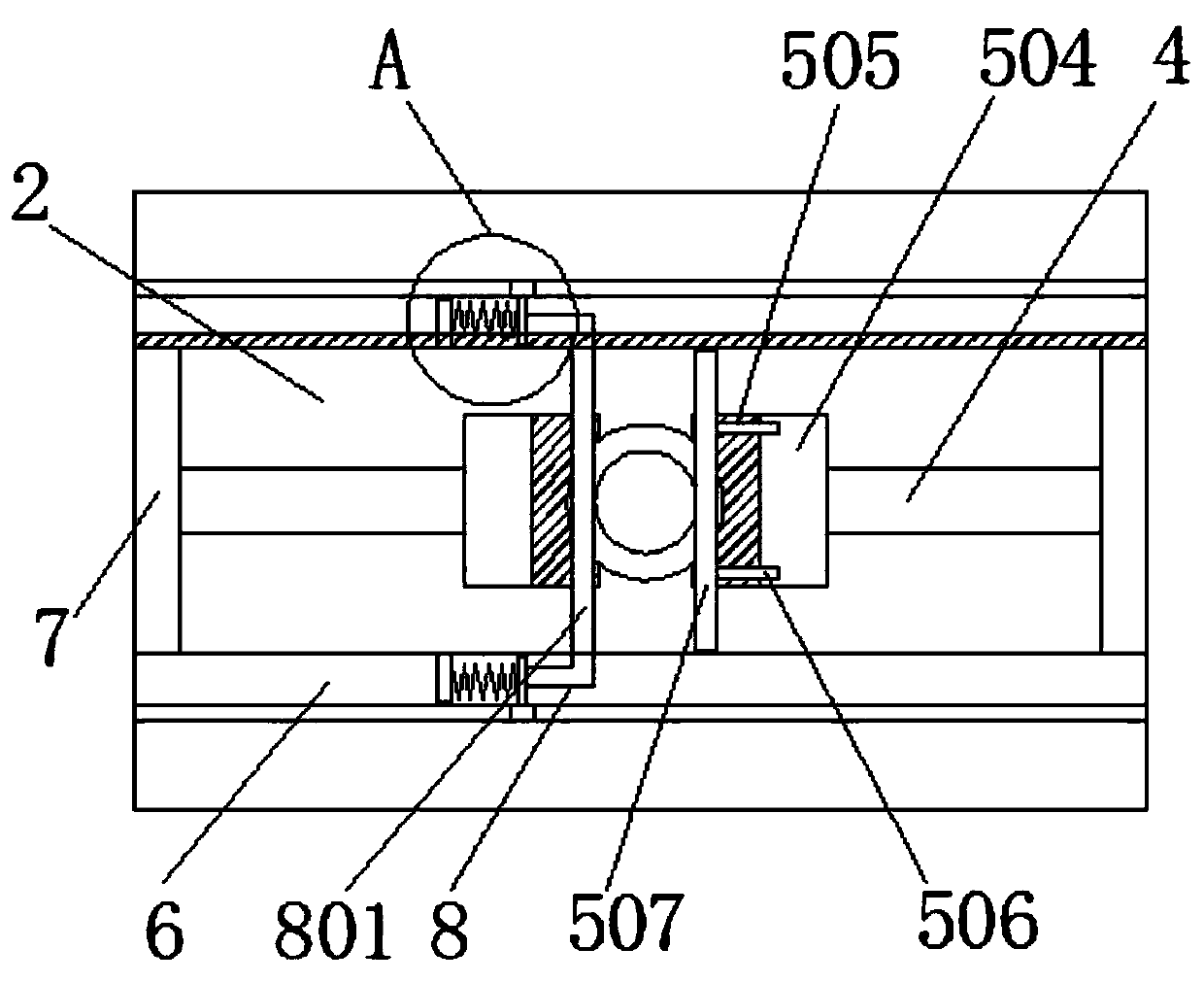

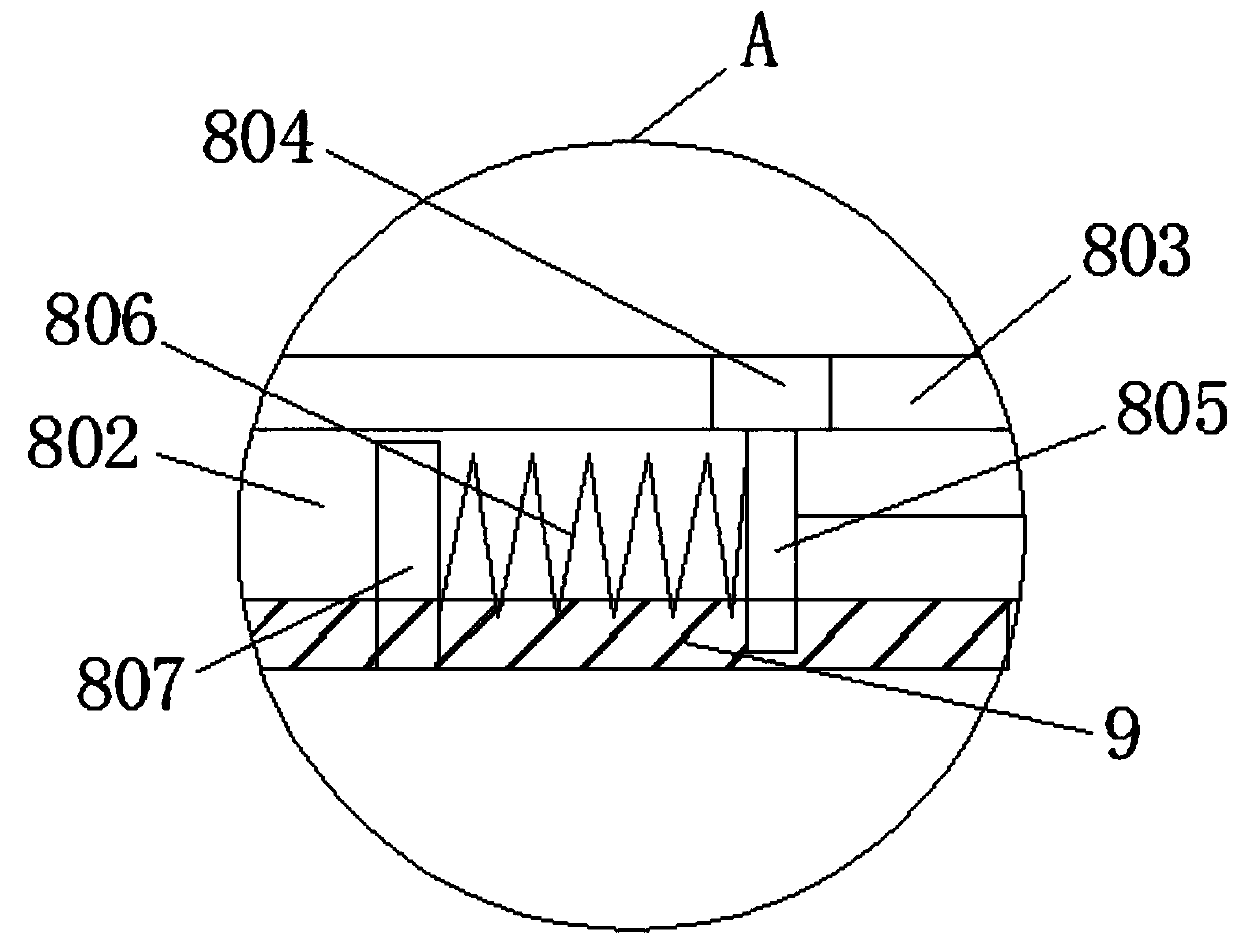

[0033] Example 1: as figure 1 — Figure 4, a detection device for a workpiece, comprising: a body 1, a support plate 2, a control panel 3, a slot 4, a clamping mechanism 5, an electric push rod 501, a slide plate 502, a slide bar 503, a connecting plate 504, and an arc splint 505 , connecting rod 506, reading rod 507, support frame 6, base plate 7, pressing mechanism 8, u-shaped resisting rod 801, inner cavity 802, first chute 803, first slider 804, resisting plate 805, first Spring 806, fixed plate 807, scale line 9, detection mechanism 10, fixed rod 1001, slide rail 1002, second slider 1003, support rod 1004, drive motor 1005, connecting shaft 1006, n-type bracket 1007, fixed inner groove 1008 , the second chute 1009, the third slider 1010, the pressure plate 1011, the L-shaped firmware rod 1012, the second spring 1013, the nut 11 and the screw rod 12, the support plate 2 is installed inside the body 1, and the outer wall of the body 1 is installed with a control There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com