Tachometer-free rotating machinery fault feature extraction method under variable rotating speed

A rotating machinery and fault feature technology, applied in the field of rotating machinery fault feature extraction, can solve the problems of high time domain resolution and frequency domain resolution, failure, and failure to meet actual needs, etc., to achieve high frequency accuracy, Precisely extracted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

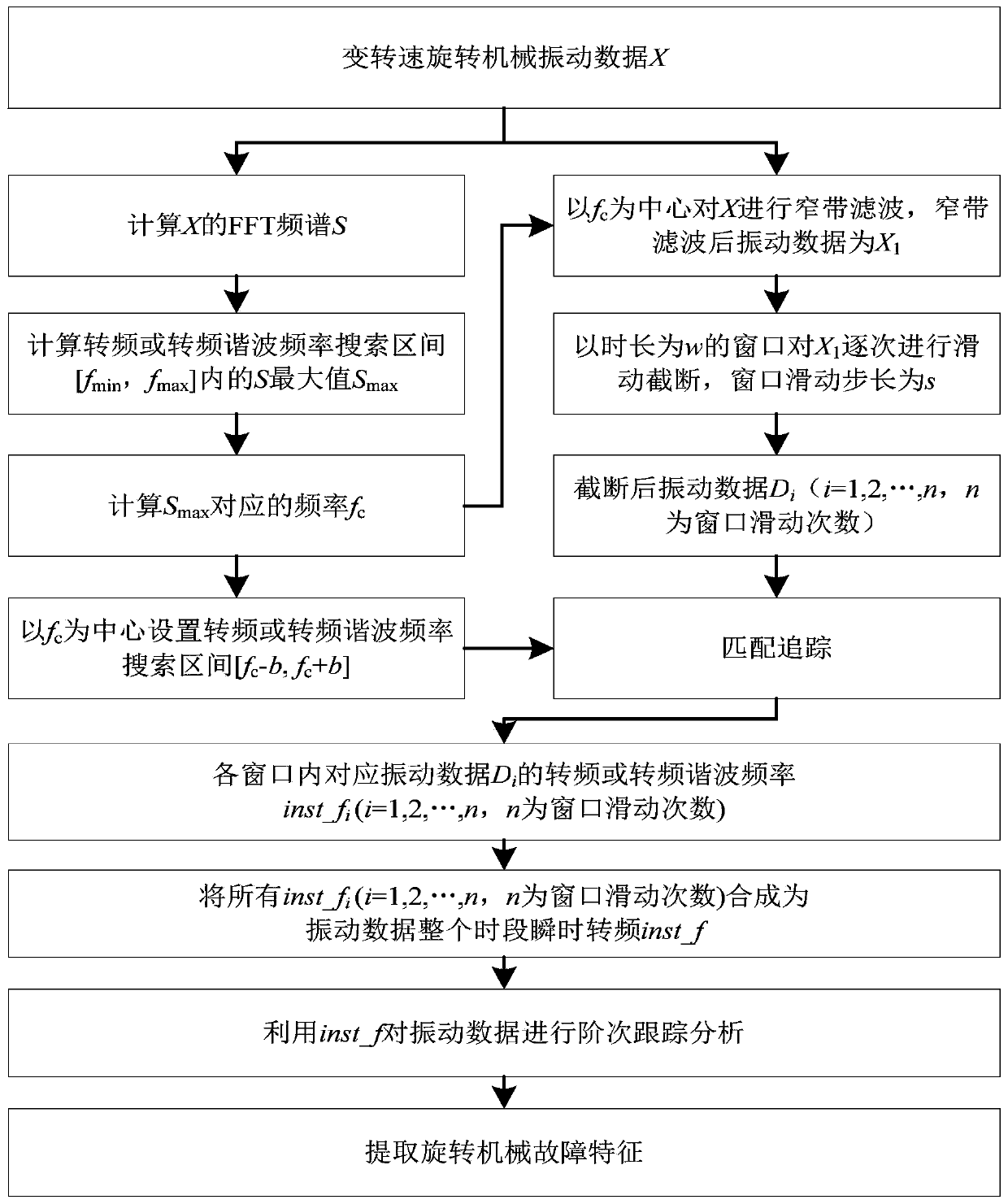

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the application clearer, the embodiments of the application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

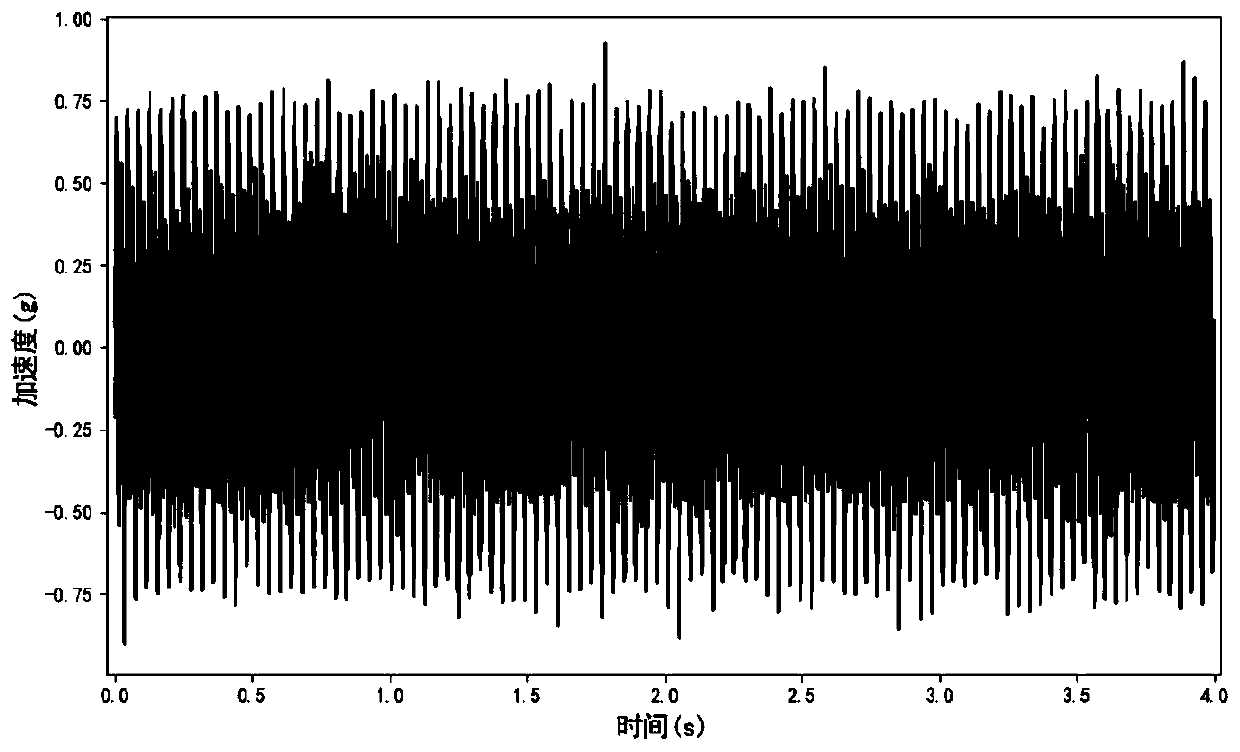

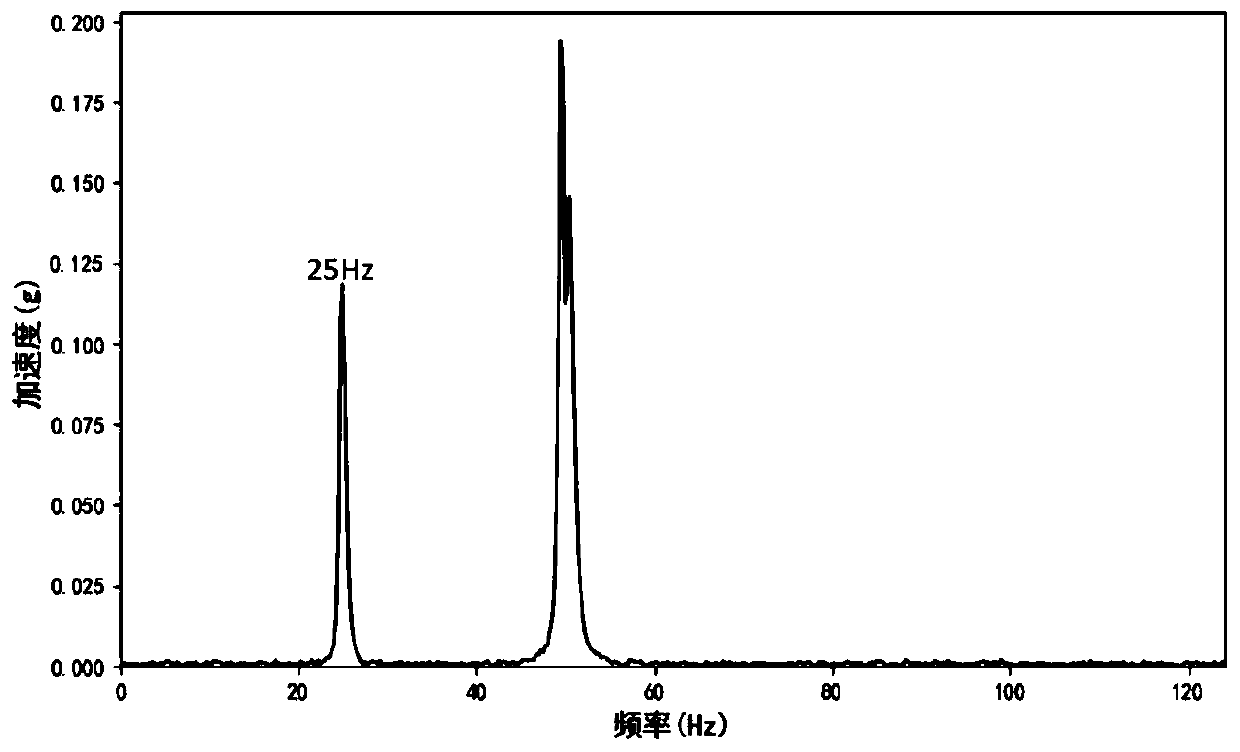

[0034] The purpose of the present invention is to design a method for extracting fault features of rotating machinery without a tachometer at variable speeds, which can realize accurate extraction of fault features of rotating machinery at variable speeds in the scene without a tachometer. A vibration sensor is provided on the rotating machine, such as an acceleration sensor, a displacement sensor or a speed sensor, and the vibration data of the rotating machine can be acquired through the vibration sensor. The rotating machines in the present application may be bearings, rotors, gears, imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com