Simple calculation method for maximum principal stress of underground diaphragm wall in excavation stage

A technology of maximum principal stress and calculation method, which is applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve the cumbersome calculation of maximum principal stress and other problems, and achieve the effects of high precision, simple calculation and simplified calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

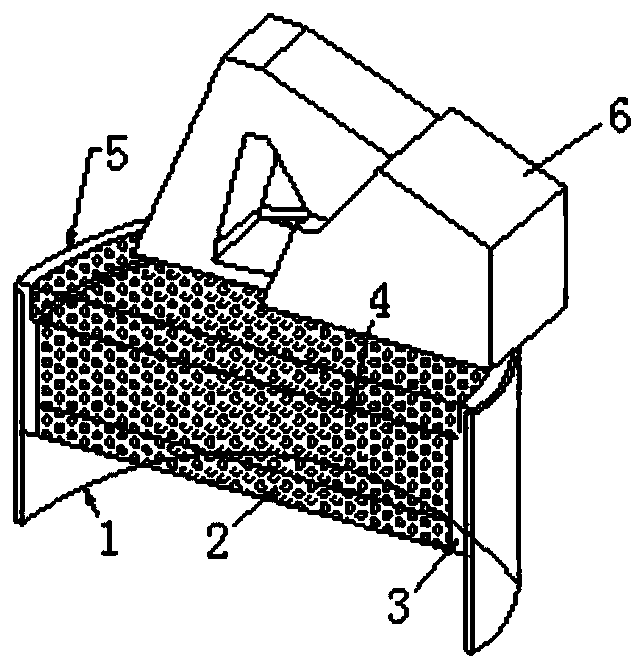

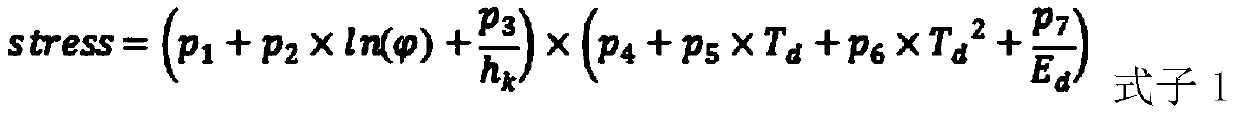

[0047] Such as Figure 1-2 As shown, a simple calculation method for the maximum principal stress of the ground connection wall in the excavation stage includes the following steps:

[0048] Step S1: Establish the finite element model of the ground connection wall excavation stage, the model is a groove body, the finite element model includes the ground connection wall 1, the bottom plate 2, the lining 3 and the filling core 4, the ground connection wall 1 is a semi-cylindrical body, The bottom of the finite element model is provided with a bottom plate 2, the inner side of the ground connection wall 1 is provided with a lining 3, the finite element model is filled with a filler core 4, and an abutment 6 is provided above the finite element model, and the ground connection wall 1 The top is the cap beam 5.

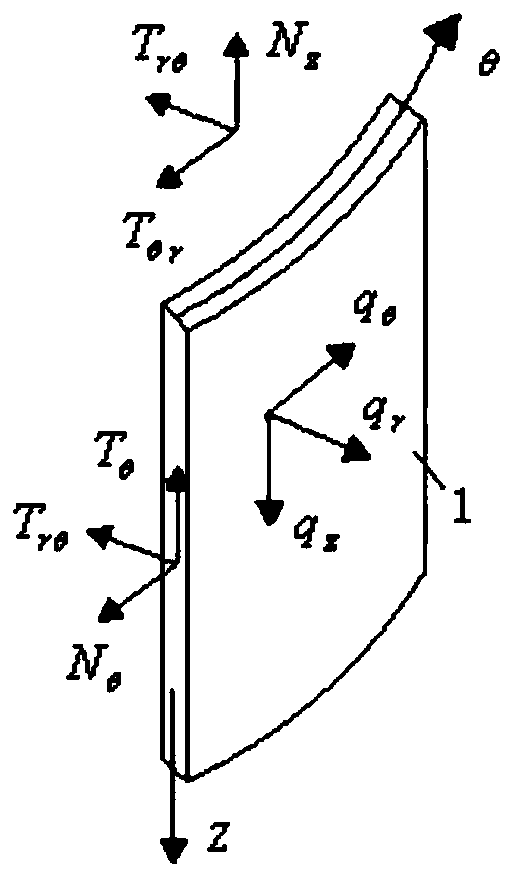

[0049] Step S2: Simplify the ground connection wall 1 into a cylindrical surface, select a cylindrical surface on the ground connection wall 1 and establish a surface coord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com