Shielding case with storable mounting position

A technology of shielding cover and installation position, applied in the field of shielding cover, which can solve the problems of contact damage on the upper part of the shielding cover shell, heat dissipation of the shielding cover, poor shock absorption effect, and reduced reliability of devices, so as to improve the heat dissipation function and heat dissipation effect Good, good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

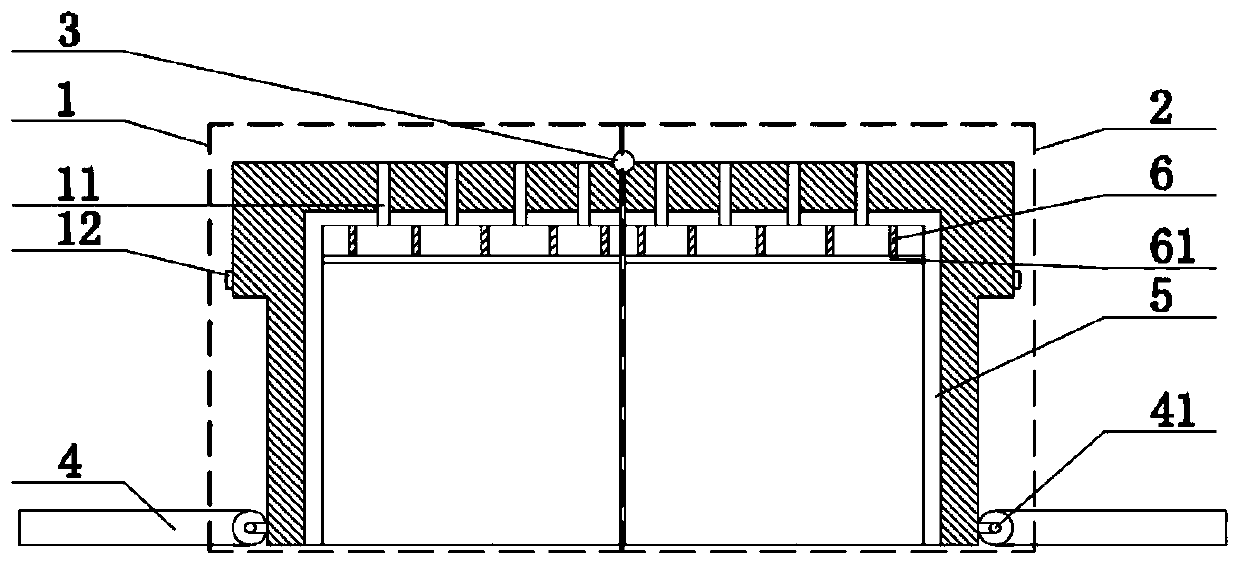

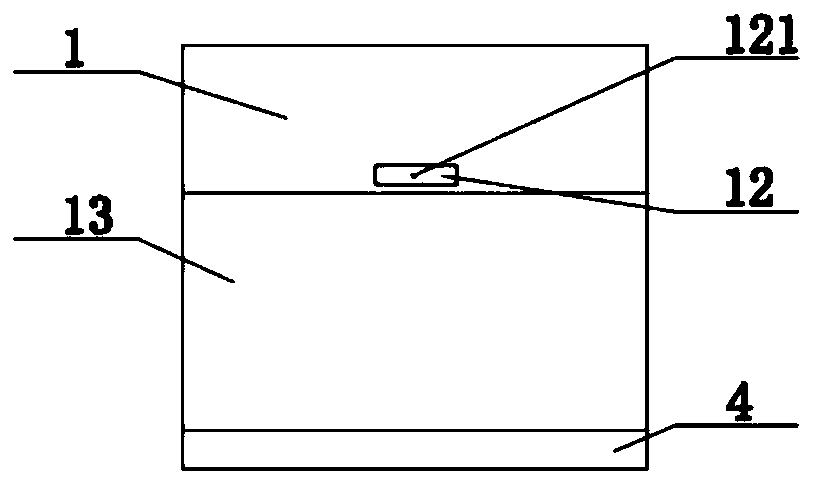

[0019] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it consists of the first shield split body 1, the second shield split body 2, the first hinge shaft 3, the mounting part 4, the insulating layer 5, and the cooling fins 6 The first shield split body 1 is provided with a heat dissipation through hole 11, and the heat dissipation through hole 11 is integrally formed with the first shield split body 1. The outer wall of the split body 1 is provided with a groove body 13, the groove body 13 is integrally formed with the first shield split body 1, the second shield split body 2 is hingedly installed on the right side of the first shield split body 1, and the second shield The cover split body 2 and the first shield split body 1 are hinged and fixed through the first hinge shaft 3, and the bottoms of the first shield split body 1 and the second shield split body 2 are both hinged and fixed to the installation part 4, and the instal...

Embodiment 2

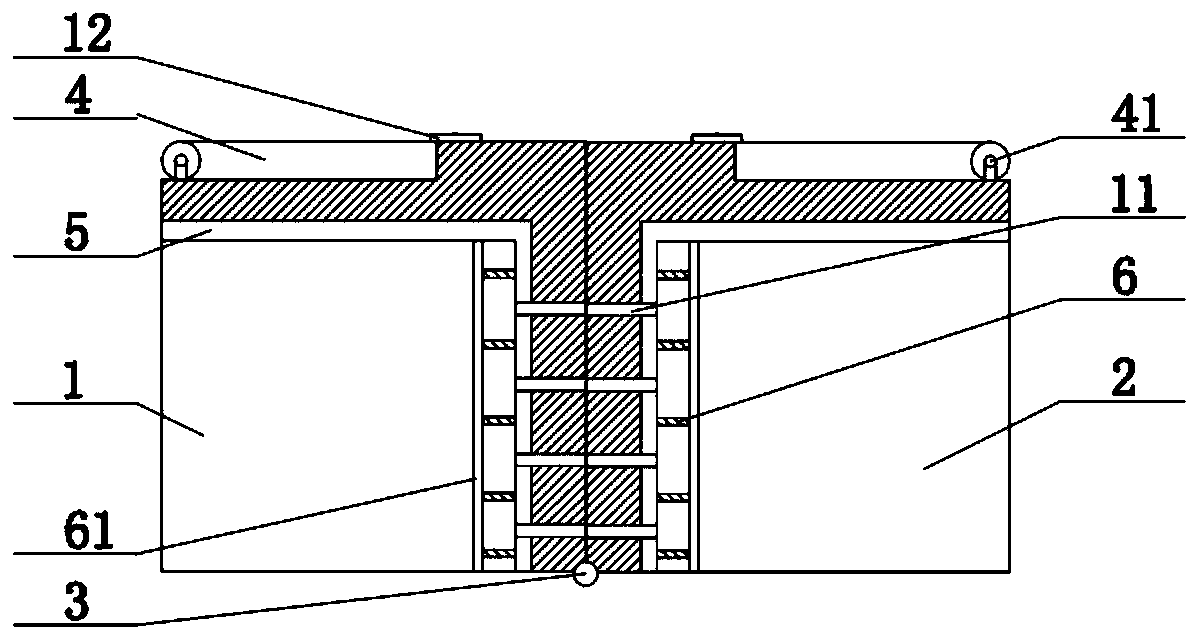

[0026] see Figure 4 As shown, the technical solution adopted in this specific embodiment is: it consists of the first shield split body 1, the second shield split body 2, the first hinge shaft 3, the mounting part 4, the insulating layer 5, and the cooling fins 6 The first shield split body 1 is provided with a heat dissipation through hole 11, and the heat dissipation through hole 11 is integrally formed with the first shield split body 1. The outer wall of the split body 1 is provided with a groove body 13, the groove body 13 is integrally formed with the first shield split body 1, the second shield split body 2 is hingedly installed on the right side of the first shield split body 1, and the second shield The cover split body 2 and the first shield split body 1 are hinged and fixed through the first hinge shaft 3, and the bottoms of the first shield split body 1 and the second shield split body 2 are both hinged and fixed to the installation part 4, and the installation pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com