Lifting system for a moment bearing, a method of mounting and dismounting a moment bearing and use of such lifting system

A technology for lifting systems and bearings, applied in the assembly of wind turbines, engines, wind power generation, etc., can solve the problems of reducing the production and maintenance costs of wind turbines, and achieve the effect of simple cost-effectiveness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

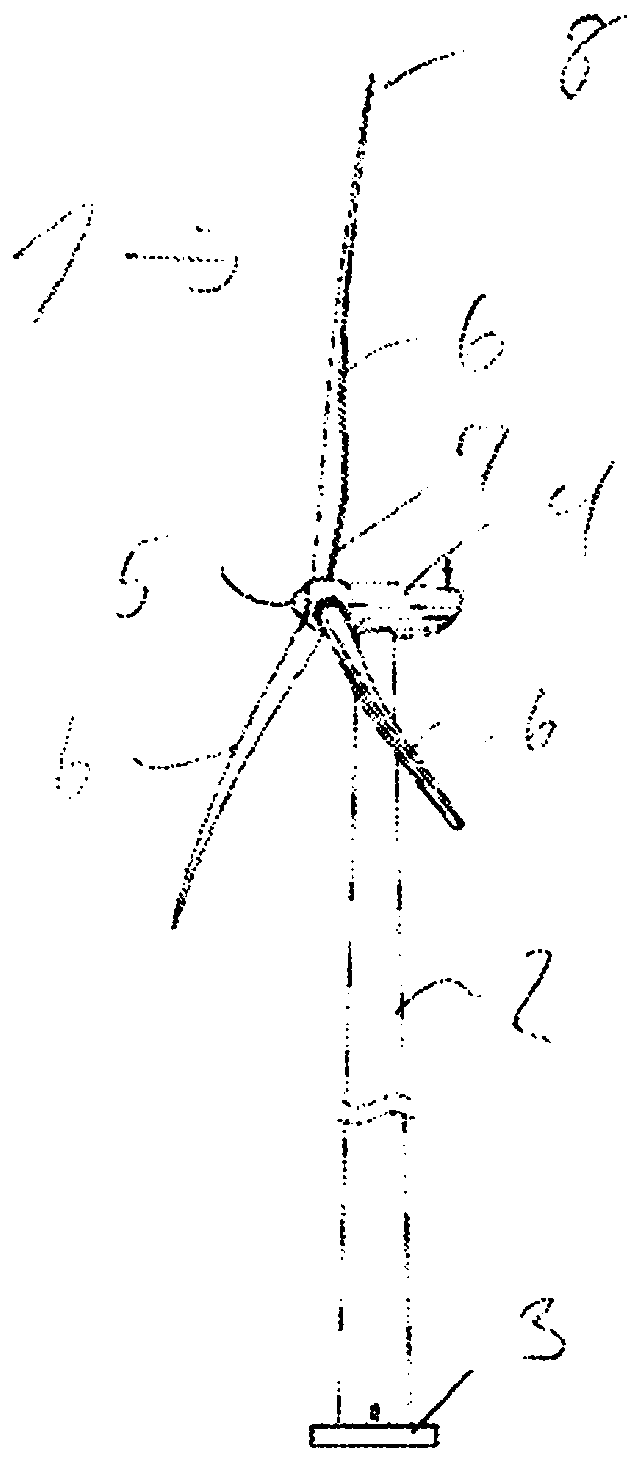

[0118] figure 1Visible in a is a typical wind turbine 1 comprising a tower 2 mounted at a foundation 3 . At the top of the tower 2 is visible a nacelle 4 comprising eg a gearbox, a generator and other components. Also installed at the nacelle 4 is a shaft for carrying the rotor, including a hub 5 and three wind generator rotor blades 6 . The rotor blade 6 is arranged at the hub 5 at a first end 7 , referred to as the root end of the rotor blade 6 . The second end 8 of the rotor blade 6 forms the blade tip.

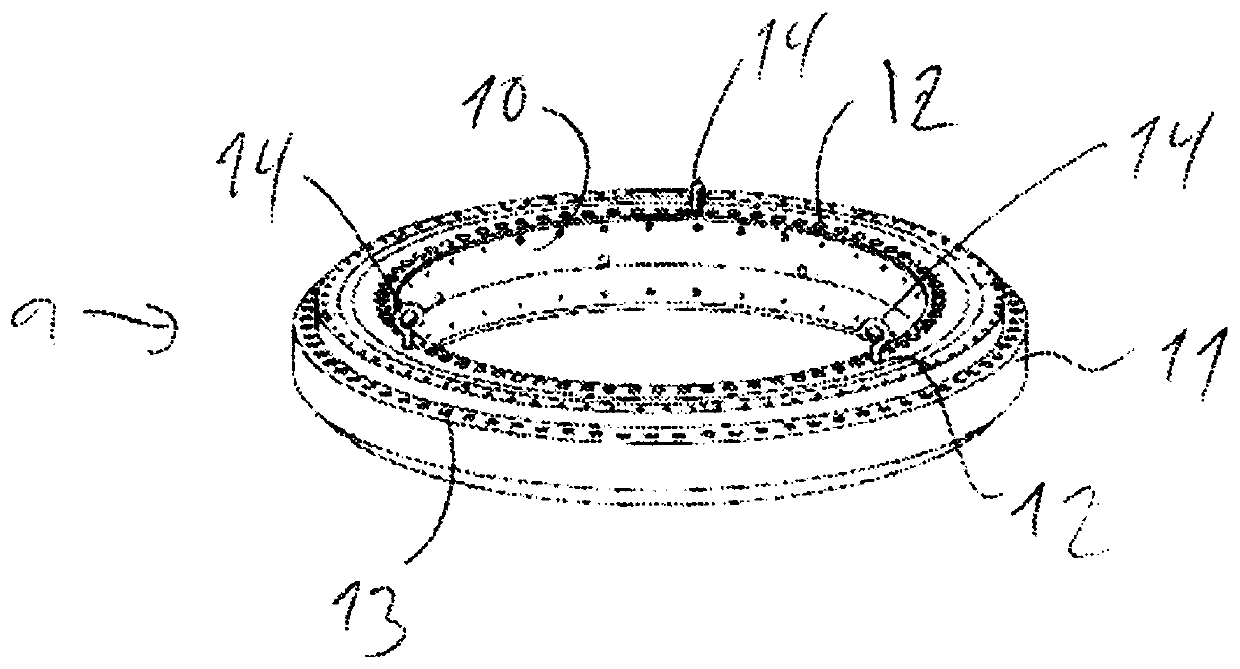

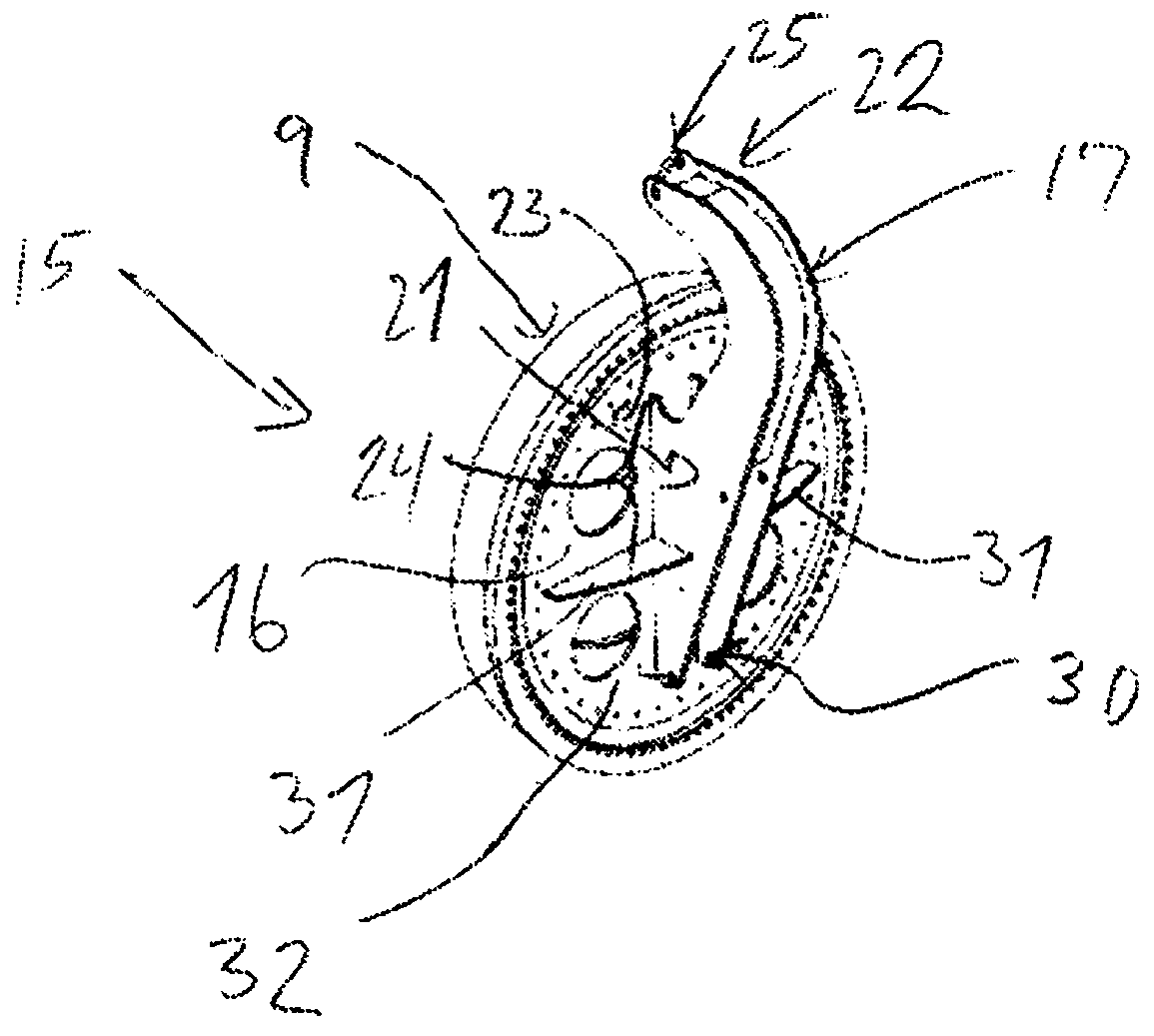

[0119] figure 2 A torque bearing 9 is shown comprising an inner ring 10 and an outer ring 11 . The inner ring is equipped with holes 12 arranged along a circle (see Figure 4 ). The outer ring also includes a plurality of holes 13 .

[0120] The holes 13 in the outer ring 11 are used to attach the torque bearing to a counterpart part on the main structure of the nacelle 4 of the wind generator. The holes 12 in the inner ring are arranged along a circle 19 (see F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com