Axial ball joint

A ball hinge, axial technology, applied in the direction of pivot, pivot connection, steering pull rod, etc., can solve problems such as steering impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

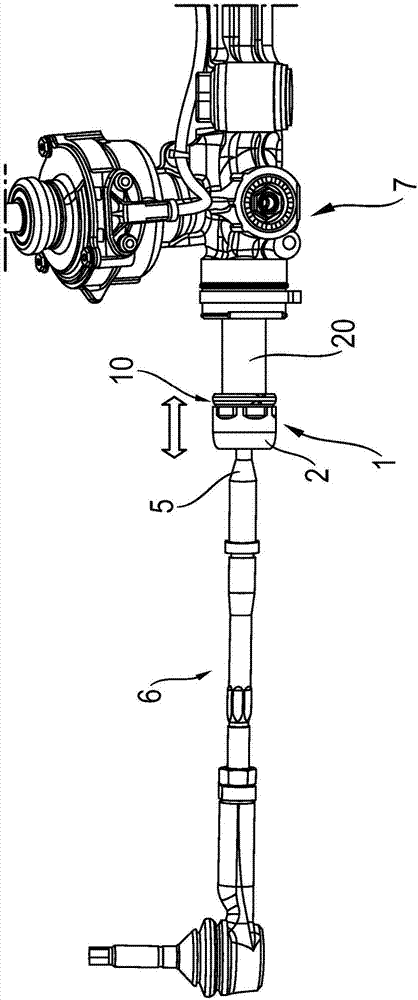

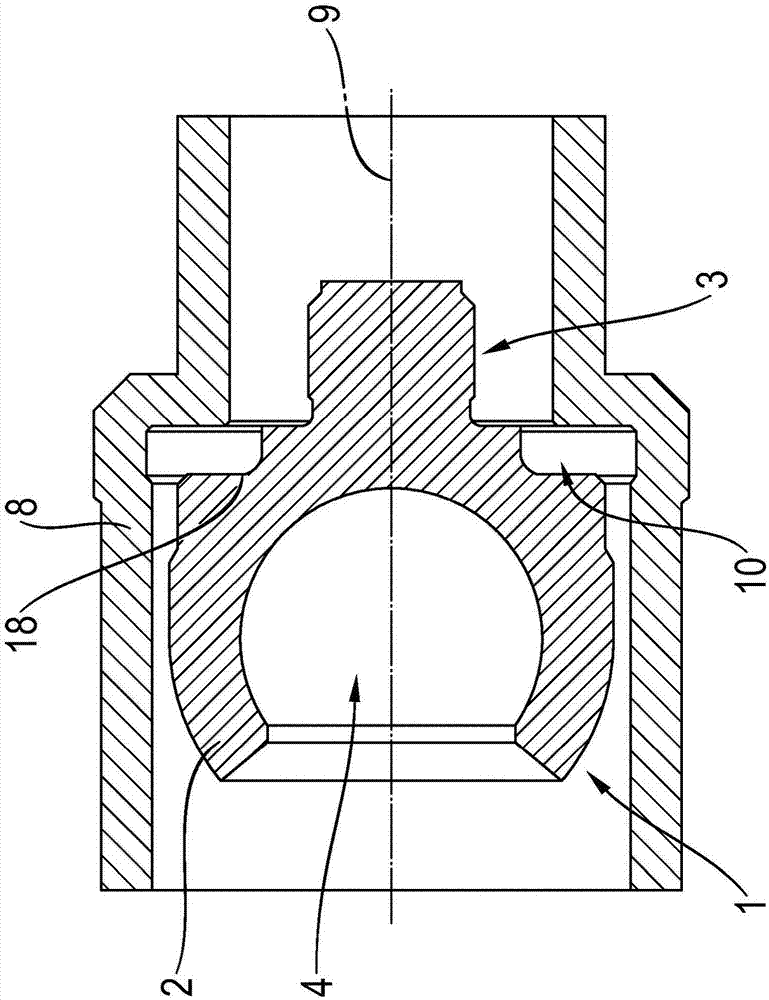

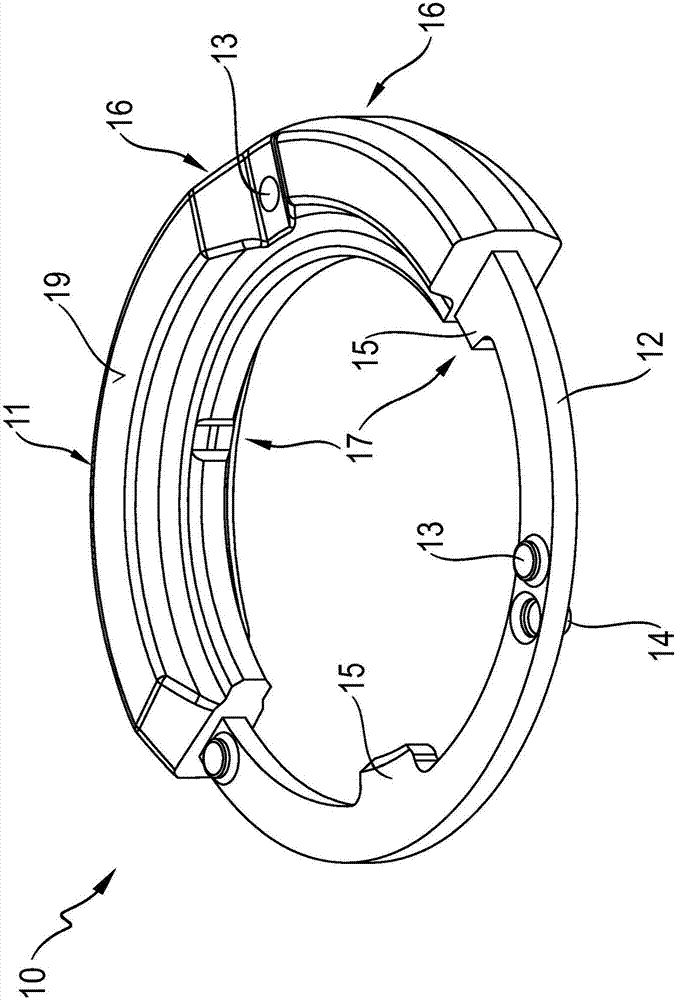

[0026] figure 1 A tie rod 6 is shown in side view, which has an axial ball joint 1 and is mechanically connected via the axial ball joint 1 to a steering gear 7 . The adjustment movement caused by the steering gear 7 brings about a displacement of the axial ball joint 1 in the direction indicated by the double arrow. The axial ball joint 1 comprises a joint housing 2 which is open on one side and which accommodates a (not shown) joint ball. The hinge ball is fastened on the hinge pin 5 , which is thus supported in a pivotable ball relative to the hinge housing 2 . A damping device 10 is arranged on the side of the hinge housing 2 facing the steering gear 7 . A damping device 10 , also called a stop damper, is mounted on the axial cup of the axial ball joint 1 . In the assembled state shown, the damper device 10 is located between the hinge housing 2 and the toothed rack 20 at the interface with the steering gear 7 .

[0027] According to the corresponding turning curve (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com