Device and method for pretreating low-fat beef

A pretreatment device, beef technology, applied in the direction of meat tenderization, processing meat, preservation of meat/fish by freezing/cooling, etc. Improve tumbling efficiency and seepage effect, uniform feeding, good thawing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

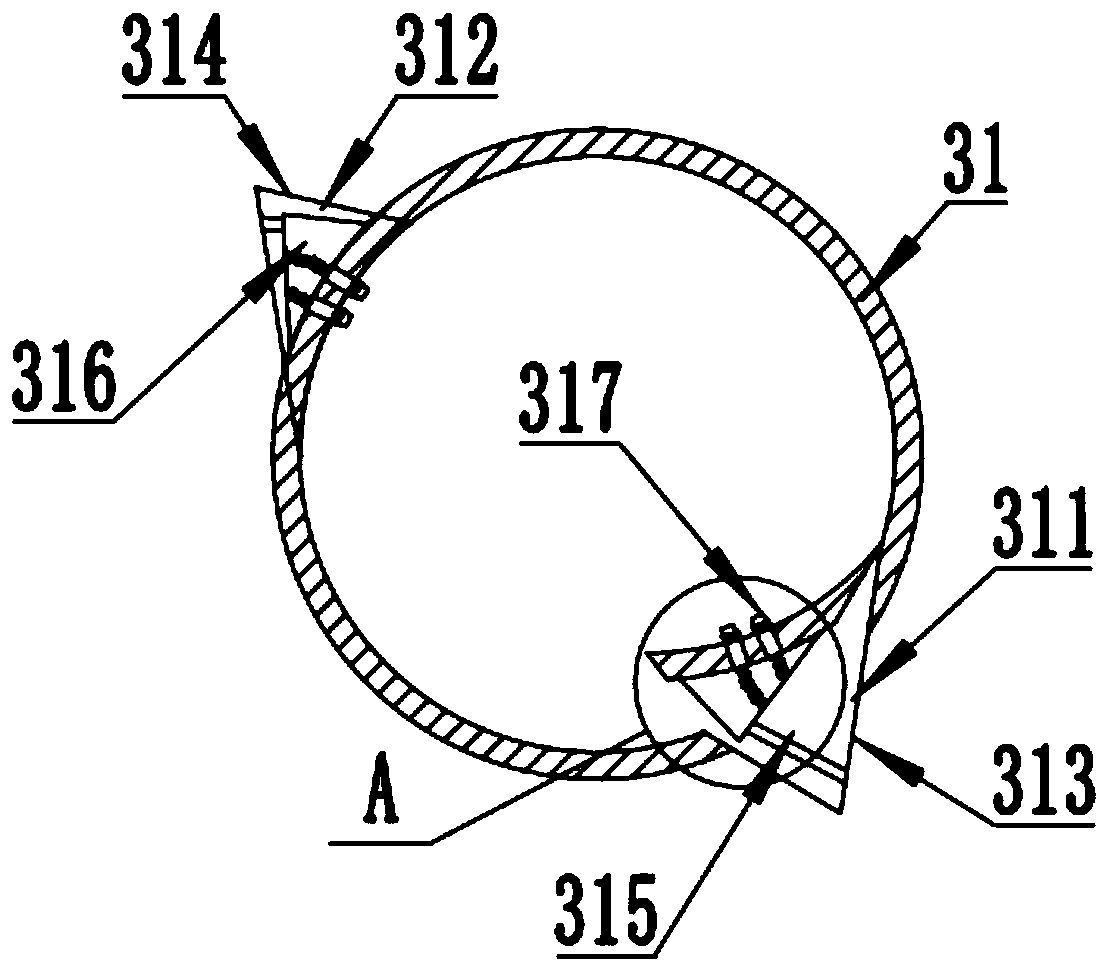

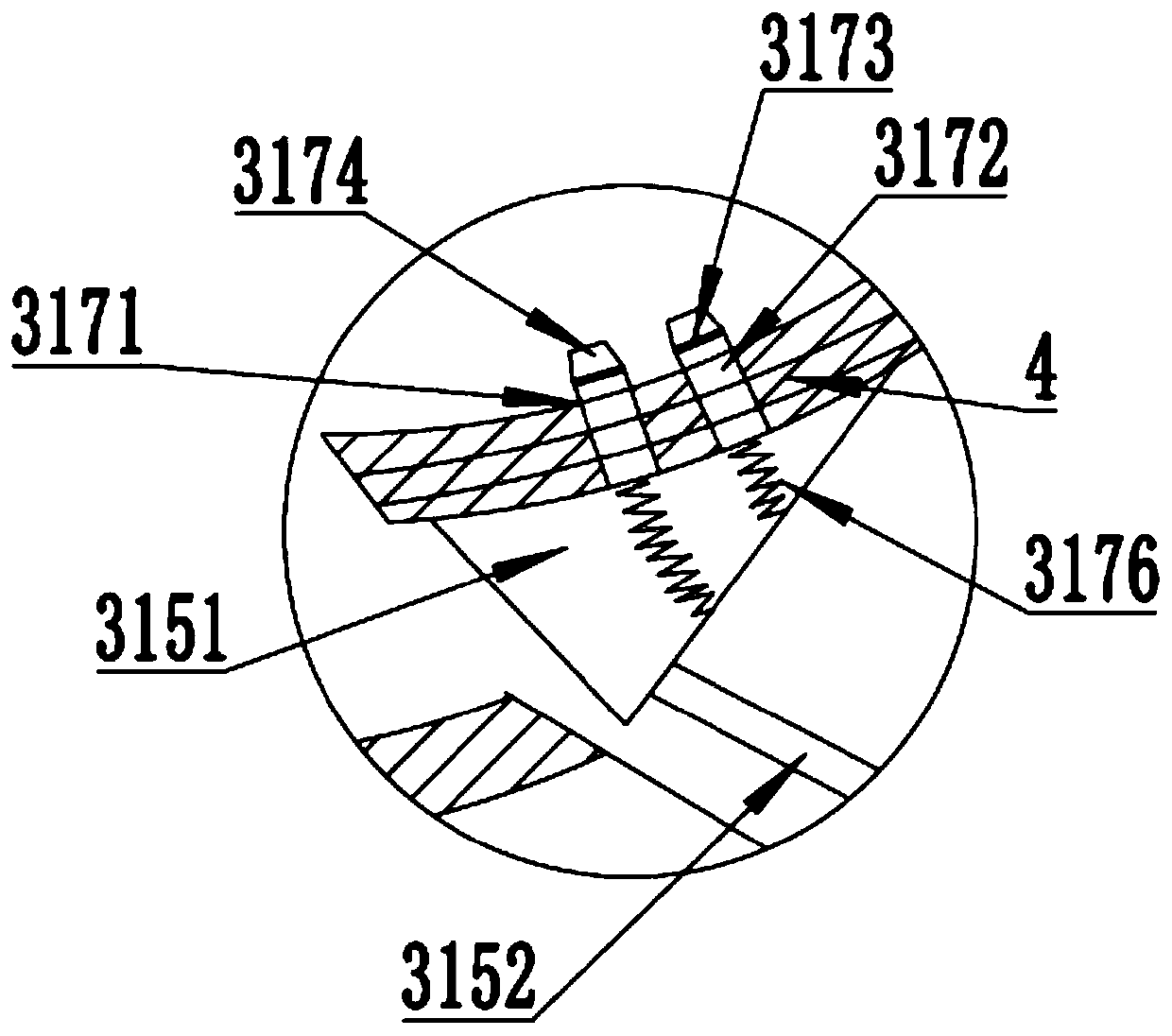

[0041] As an embodiment, the weighing mechanism includes a support rod connected to both ends of the cylinder 31 and a weight sensor installed at the bottom of the support rod.

[0042] As an embodiment, both the first cavity 3151 and the side of the second cavity are connected with a rotatable transition plate, and when the first cavity 3151 and the second cavity extend out, the transition plate can be rotated for The transition between the first cavity 3151 , the second cavity and the inner wall of the cylinder 31 prevents the beef from being stuck between the first cavity 3151 , the second cavity and the cylinder 31 .

[0043] As an implementation, both the first cavity 3151 and the second cavity are equipped with a liquid level switch, and the liquid level switch is connected with a buzzer to prompt the liquid level in the first cavity 3151 and the second cavity, which is convenient The user knows the liquid level in the first cavity 3151 and the second cavity, for example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com