Wall mounting type frozen chicken unfreezing mechanism and unfreezing method

A wall-mounted, chicken technology, which is applied in the direction of freezing/cooling to preserve meat/fish, etc. It can solve the problems of long thawing time, inability to hang the mechanism, poor heating uniformity of chicken, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

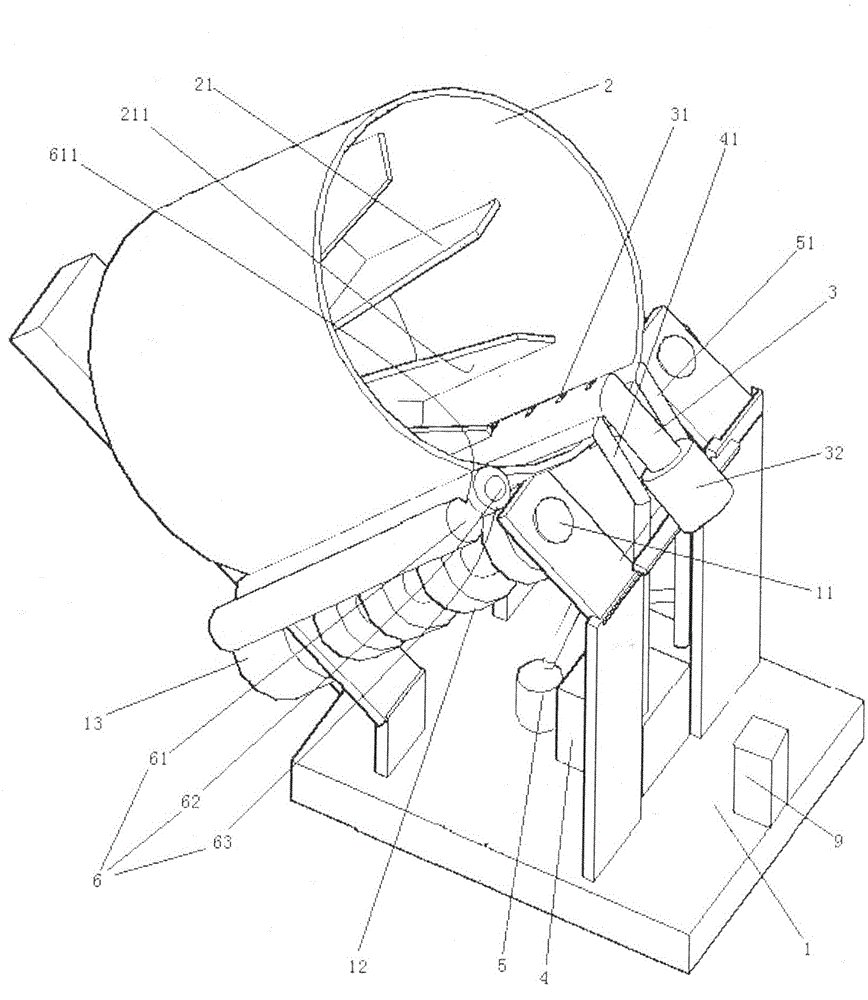

[0030] Embodiment one, see figure 1 A wall-mounted frozen chicken thawing mechanism includes a frame 1, a bucket 2, an air blowing pipe 3, a thermostat 4, a circulation pump 5 and a wiping mechanism 6.

[0031] The frame 1 is provided with a pair of support shafts 11 in an inclined state. The support shaft 11 is rotatably connected to the frame 1 . A pair of support shafts 11 are distributed along the left and right directions. The two supporting shafts 11 are parallel. The support shaft 11 is provided with several drive wheels 12 distributed along the axial direction. The one on the left side in the pair of supporting shafts 11 is connected with the driving motor 13 . The drive motor 13 is connected to the lower end of the support shaft. This can improve the stability of the present invention. The frame 1 is also provided with a suspension frame 9 .

[0032] Bucket 2 is the little truncated cone shape of bottom big upper end (being open end). The bucket 2 rests on the...

Embodiment 2

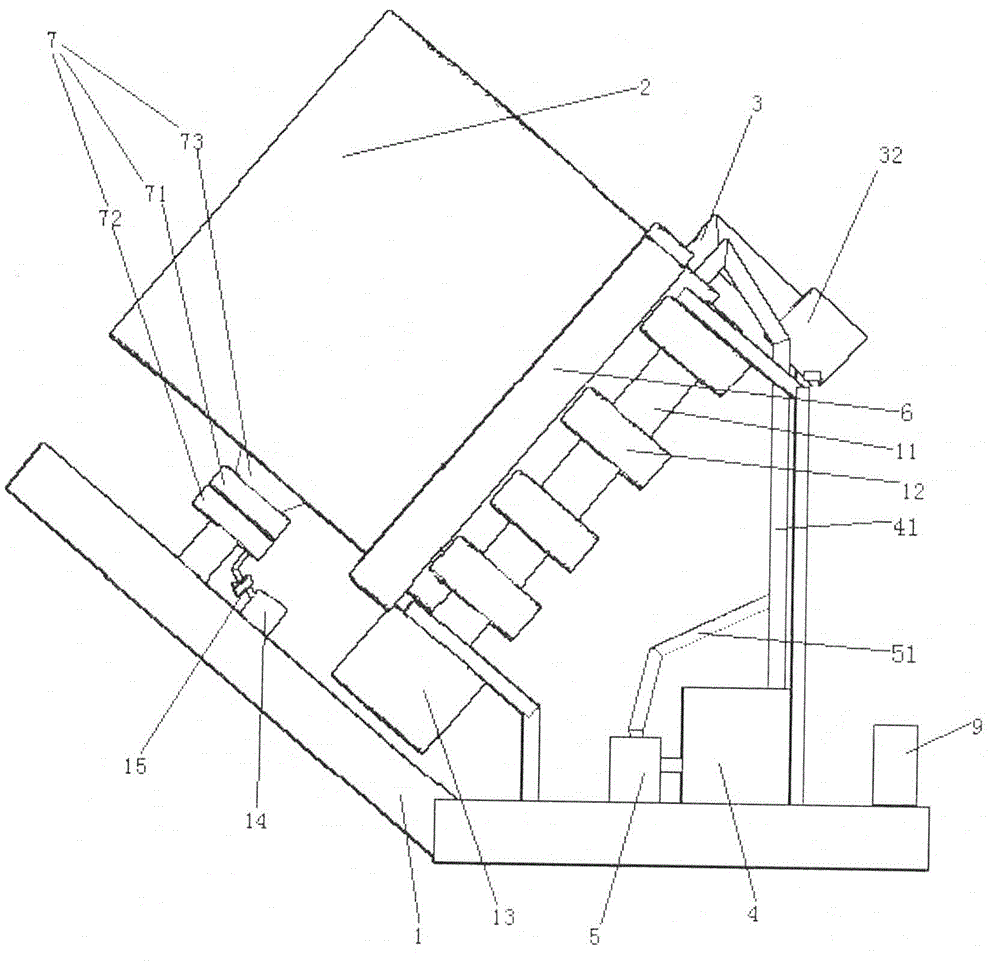

[0072] Embodiment two, the difference with embodiment one is:

[0073] see Figure 5 , also includes a coating heating mechanism 8. Suspension bar 9 is the arc structure that arches downwards (certainly upwards is also possible). The coating heating mechanism 8 includes a case shell 80 , a swing rod 87 and a driving motor 88 . The swing rod 87 is provided with an applicator head 871 . The applicator head 871 is ring-shaped. The coating head 871 is sheathed on the suspension rod 91 . The drive motor 88 is fixed to the case 80 . The case shell 80 is fixed together with the frame 1.

[0074] see Figure 6 , The coating heating mechanism 8 also includes a power input shaft 86, a swing shaft 81, a swing gear 82, a forward drive gear 83, a reverse drive gear 84 and a reversing gear 85 located in the case. The swing shaft 81 is rotatably connected to the casing 80 . The swing gear 82 is connected to the swing shaft 81 . The forward drive gear 83 is connected to a power inpu...

Embodiment 3

[0078] Embodiment three, the difference with embodiment two is:

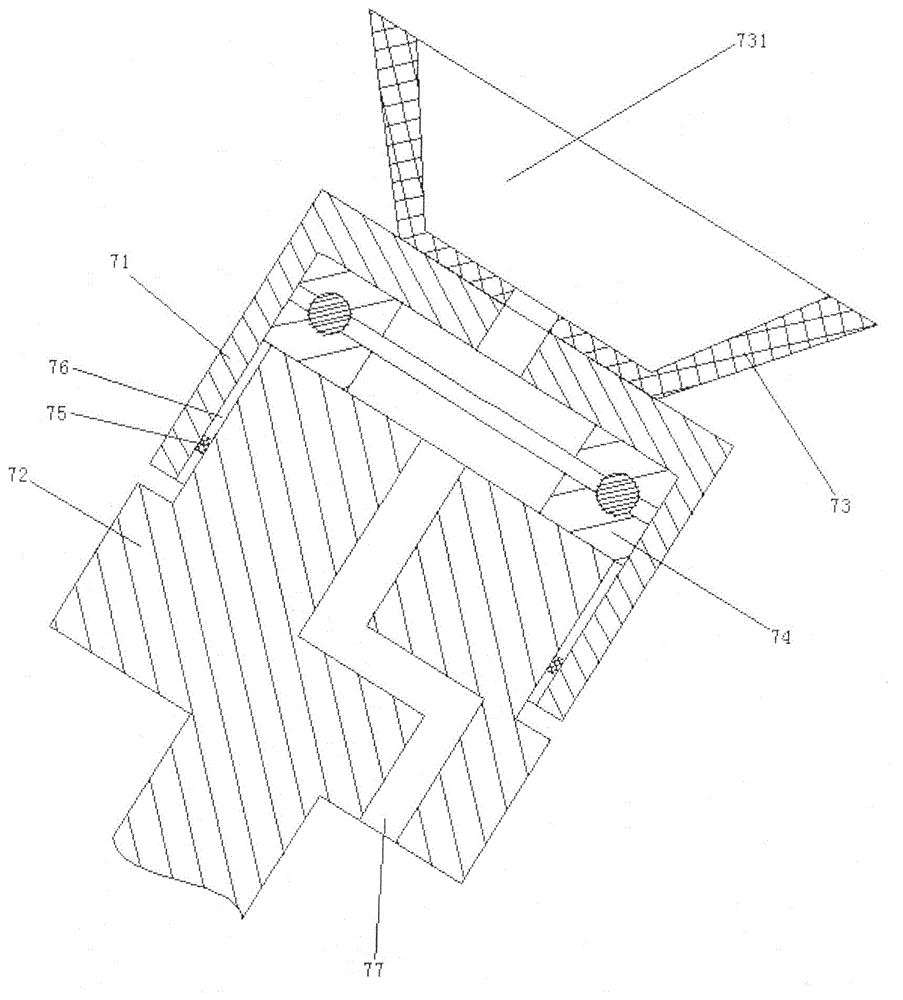

[0079] see Figure 8 , the squeeze roller 61 is also rotatably connected to the frame 1 (see figure 1 )of. Squeeze roll also is by drive motor 13 (referring to figure 1 )Driven. The wiping mechanism 6 also includes a water receiving tank 66, that is, the water receiving tank replaces the gutter. The water receiving groove 66 is located below the extrusion place of the extrusion roller 61 . The linear velocity of the contact point 632 between the water-absorbing block and the surface of the squeeze roller is equal to the linear velocity of the surface of the squeeze roller 611. During use, the rotation direction of the mandrel 62 is from bottom to top, that is, direction C in the figure, which is opposite to the rotation direction of the first embodiment. The rotation direction of squeeze roller 61 is opposite to the rotation direction of the mandrel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com