Infusion drip chamber device with replaceable dimensions

A specification and size technology, applied in the field of infusion dripping device, can solve problems such as slipping out and inapplicability of infusion dripping device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

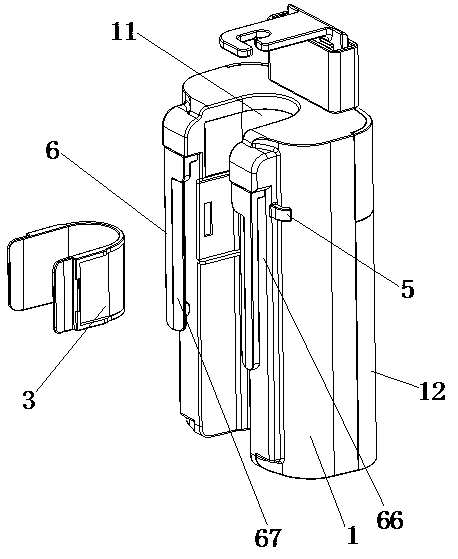

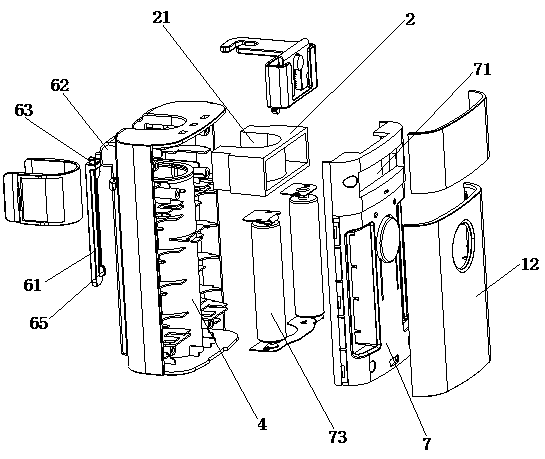

[0033] Embodiment one, with reference to Figure 1 to Figure 3It can be seen that it includes a plastic shell 1, a sensor component 2, a dropper specification and size adapting component 3, a control board, an anti-slip component 5 and a pocket clamping component 6, and one side of the plastic shell 1 is provided with a cover snap-fitted with it Plate 12, the other side of the plastic shell 1 is provided with a mounting groove 11, the mounting groove 11 in this embodiment can be a U-shaped mounting groove, the anti-slip component 5, the sensor component 2 and the pocket clamping component 6 are all arranged in the The side of the plastic housing 1 close to the installation groove 11, the installation cavity 4 is formed between the cover plate 12 and the plastic housing 1, the control main board is arranged in the installation cavity 4, and the control main board is electrically connected with the sensor component 2, and the specification of the dropping funnel The size adaptat...

Embodiment 2

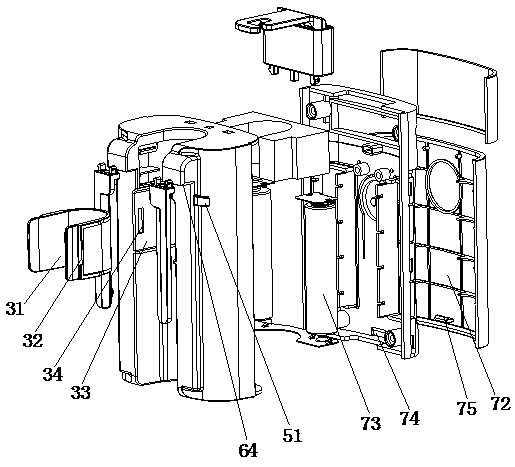

[0035] Embodiment two, refer to Figure 4 As a further improvement of Embodiment 1, inflatable airbags 35 are fixedly installed on both sides of the inner surface of the shrapnel 31, and the two inflatable airbags 35 are connected through the air bag 36. An air pump 37 is arranged under the shrapnel 31, and the air pump 37 is fixed. Connect one end of the inflatable tube 38, the other end of the inflatable tube 38 passes through the shrapnel 31 and communicates with the inflatable end of one of the inflatable airbags 35, the inflatable end of the inflatable airbag 35 is provided with a one-way valve; the side wall of the installation groove 11 is provided with an inflatable In the pump placement groove 9 , after inserting the shrapnel 31 into the installation slot 33 , the air pump 37 can be placed in the air pump placement groove 9 . When monitoring the infusion dripping funnel of smaller specifications, after the medical personnel place the infusion dripping funnel in the sh...

Embodiment 3

[0036] Embodiment three, refer to Figure 5-7 , as a further improvement of the first embodiment, the present application also includes a guide clamping device 8, which is fixedly installed under the plastic housing 1, and a positioning groove 81 is opened on the guide clamping device 8. Both sides of the positioning groove 81 are provided with through holes, and both sides of the positioning groove 81 are provided with chute 82. In the chute 82, a partition block 83 is slidingly connected, and one side of the partition block 83 moves in the positioning groove 81 through the through hole. Inside, the other side of the partition block 83 is fixedly equipped with an inclined block 84, and the side of the chute 82 is fixedly equipped with a telescopic motor 85, and the driving end of the telescopic motor 85 is movably connected to one end of the telescopic rod 86, and the other end of the telescopic rod 86 is provided with The inclined surface matched by the inclined block 84; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com