Combined type building form

A building formwork and combined technology, applied in the direction of mold panels, molds, mold trays, etc., can solve the problems of high cost, inconvenient carrying and transportation, etc., and achieve the effect of convenient carrying and transportation and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

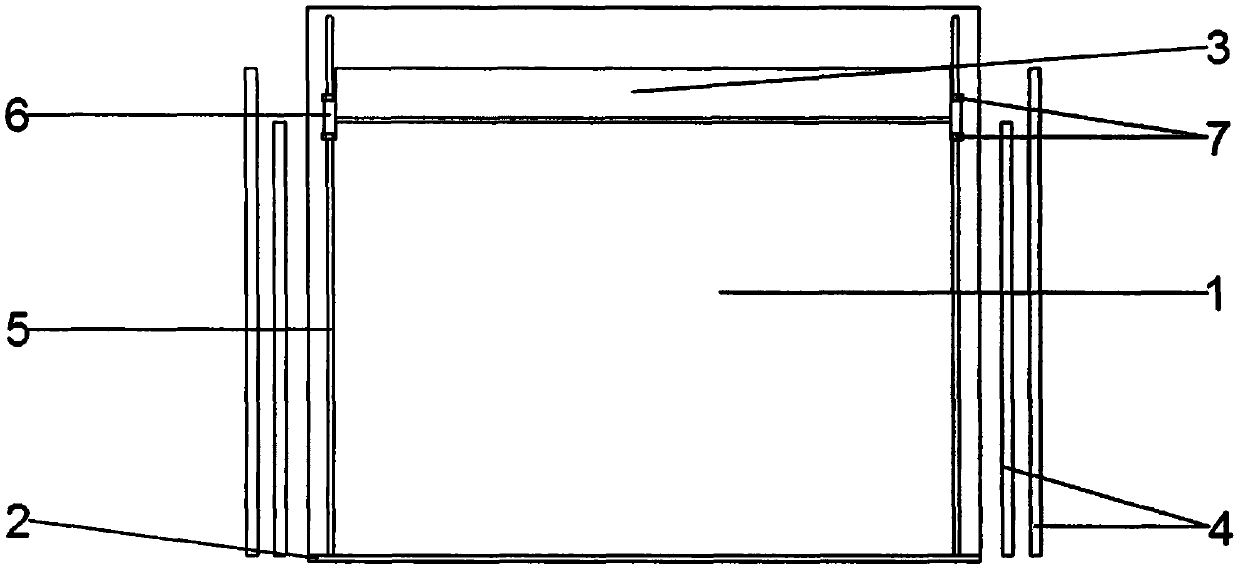

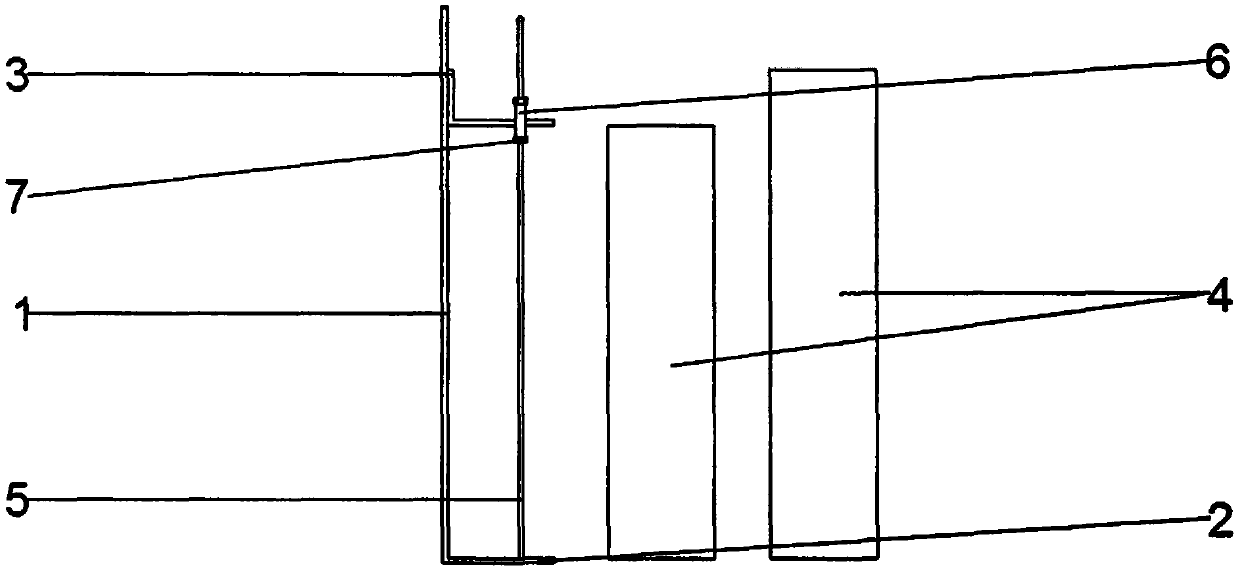

[0017] combine figure 1 and figure 2 , the combined building formwork includes a rectangular plate-shaped panel 1 and a number of rectangular plate-shaped side panels 4 of different lengths, the bottom end of the panel 1 is vertically provided with a rectangular plate-shaped fixed end plate 2, and the panel 1 is provided with an L-shaped plate shaped movable end plate 3, the movable end plate 3 is closely attached to the panel 1, the width of the movable end plate 3 is smaller than the width of the panel 1, and two circular tube-shaped sleeves 6 are vertically arranged on both sides of the movable end plate 3, The two sleeve pipes 6 are perpendicular to the fixed end plate 2, and the fixed end plate 2 is vertically provided with two cylindrical threaded rods 5, and the two threaded rods 5 pass through the two sleeve pipes 6 respectively, and the two threaded rods 5 are equipped with two threaded rods respectively. A threaded nut 7. The panel 1, the fixed end plate 2, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com