Special disc buckle formwork support for arc-shaped building structure

A technology for building structures and formwork supports, which is applied to building structures, on-site preparation of building components, construction, etc., can solve problems such as inability to apply arc-shaped building structure systems, achieve simple structure, increase installation speed, and ensure installation quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

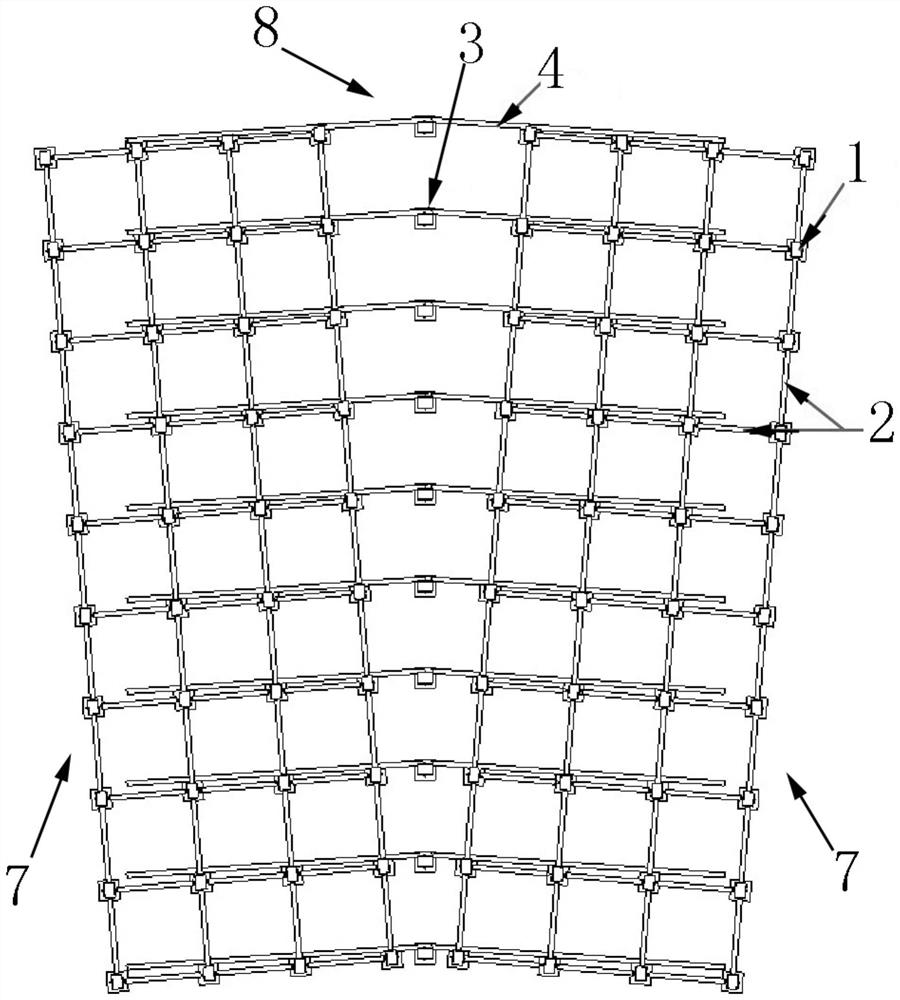

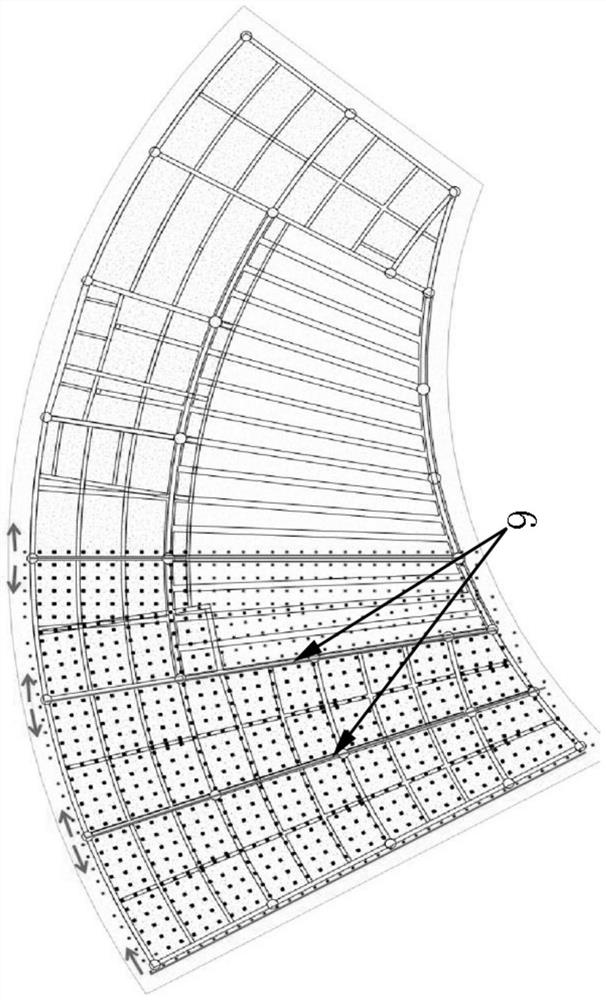

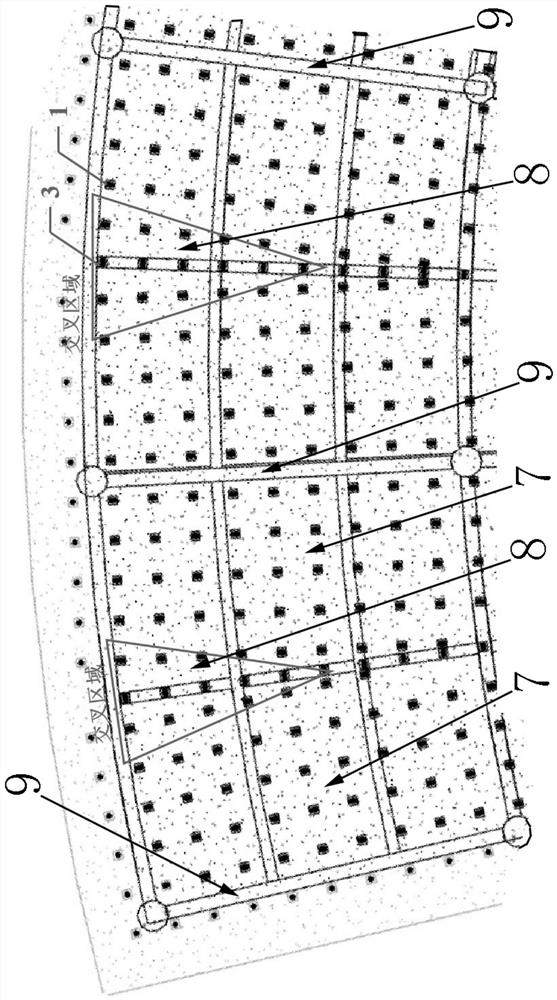

[0028] Example 1, as Figure 1-6 As shown, the present invention provides a special disk buckle support formwork for an arc-shaped building structure, including a regular disk-buckle support formwork 7 that is synchronously and evenly erected to both sides with the main beam 9 of the arc-shaped building structure as the center, and is erected on the opposite side. The cross-connection disc buckle formwork frames 8 are connected between the main beams 9 of the adjacent arc-shaped building structures and are respectively connected with the two regular disc buckle support formwork frames 7 between the adjacent arc-shaped building structure main beams 9 .

[0029] The invention has the advantages of simple structure, scientific and reasonable design, and convenient use. By creatively arranging and designing the buckle frame body, a cross-connection area that partially does not conform to the connection modulus of the buckle frame body is formed, and then the cross-connection area i...

Embodiment 2

[0030] Example 2, as Figure 1-6 As shown, the present invention provides a special disk buckle support formwork for an arc-shaped building structure, including a regular disk-buckle support formwork 7 that is synchronously and evenly erected to both sides with the main beam 9 of the arc-shaped building structure as the center, and is erected on the opposite side. The cross-connection disc buckle formwork frames 8 are connected between the main beams 9 of the adjacent arc-shaped building structures and are respectively connected with the two regular disc buckle support formwork frames 7 between the adjacent arc-shaped building structure main beams 9 . The cross-connection disc buckle support formwork 8 includes a cross-connection disc buckle frame pole 3 and a fastener-type steel pipe cross bar 4 mounted on the cross-connection disc buckle frame pole 3; the cross-connection disc buckle frame pole 3 passes through the fasteners The steel pipe cross bar 4 is overlapped with the ...

Embodiment 3

[0032] Example 3, as Figure 1-6 As shown, the present invention provides a special disk buckle support formwork for an arc-shaped building structure, including a regular disk-buckle support formwork 7 that is synchronously and evenly erected to both sides with the main beam 9 of the arc-shaped building structure as the center, and is erected on the opposite side. The cross-connection disc buckle formwork frames 8 are connected between the main beams 9 of the adjacent arc-shaped building structures and are respectively connected with the two regular disc buckle support formwork frames 7 between the adjacent arc-shaped building structure main beams 9 . The cross-connection disc buckle support formwork 8 includes a cross-connection disc buckle frame pole 3 and a fastener-type steel pipe cross bar 4 mounted on the cross-connection disc buckle frame pole 3; the cross-connection disc buckle frame pole 3 passes through the fasteners The steel pipe cross bar 4 is overlapped with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com