A fire-resistant unit window

A fire-resistant and window-shaped technology, applied in the field of unit windows, can solve the problems of difficult control of the final product quality of doors and windows, reduce the basic performance of doors and windows, and many installation procedures, so as to prolong the time of evacuation and escape, improve structural stability and fire resistance , Improve the effect of fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Refractory inner skeleton

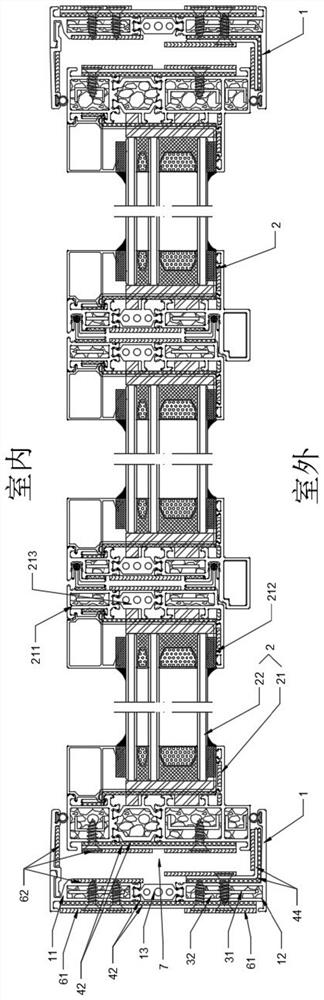

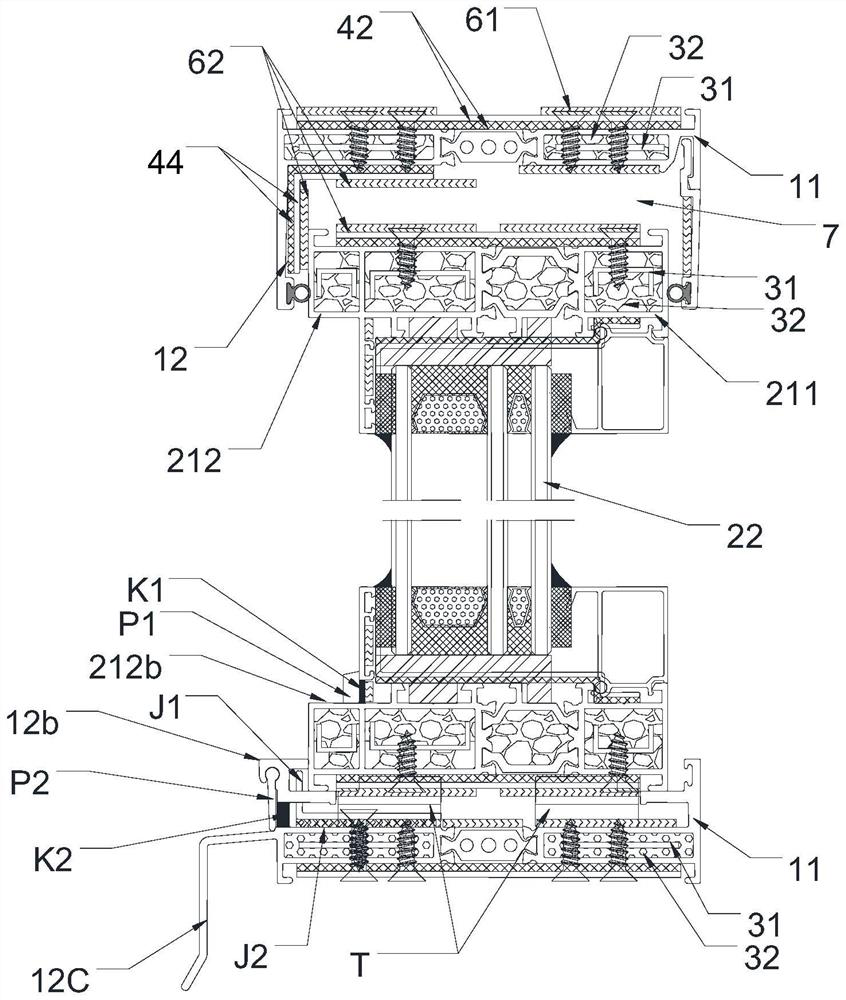

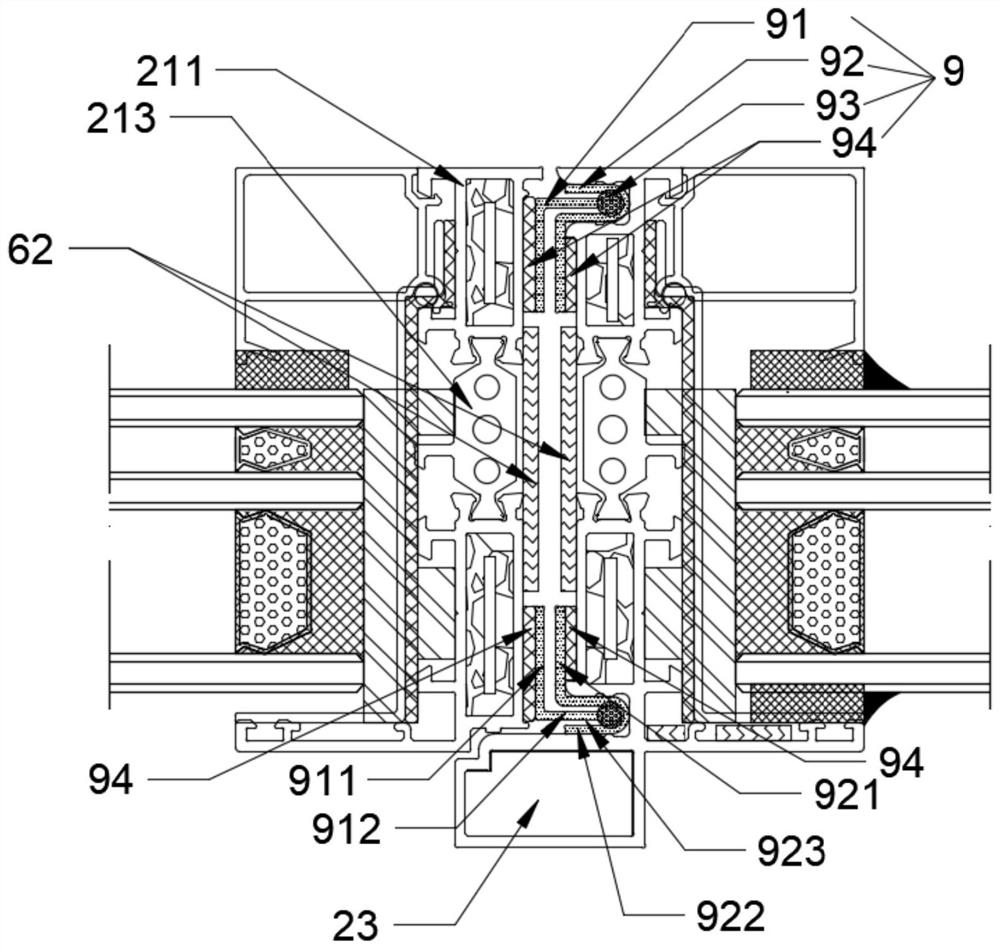

[0059] like Figure 1-2 A fire-resistant unit window shown includes an outer frame 1 for connecting with a wall, at least two unit windows 2 installed in the outer frame 1 , and the unit windows 2 include a window frame body 21 and a window glass 22 . In this embodiment, there are three unit windows, and the number of unit windows and outer frame specifications can be designed according to actual needs.

[0060] In order to improve the energy-saving and heat-insulating performance of the unit window, the window frame body 21 and the outer frame 1 are heat-insulating structures, and the window frame body 21 includes a window frame inner layer 211, a window frame outer layer 212 and an insulating strip 213 connecting the former two . The outer frame 1 includes an inner layer 11 of the outer frame, an outer layer 12 of the outer frame and a heat insulation strip 13 connecting the former two. The two types of insulation strips are basically so...

Embodiment 2

[0128] The structure of the refractory unit window of this embodiment is the same as that of Embodiment 1, the difference is that the window frame body 21 and the outer frame 1 are non-insulated structures, which reduces the manufacturing cost of the unit window and simplifies the processing technology .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com