Weld bead pressing and burr rolling integrated device

A welding bead and burr technology is applied in the field of pressure welding bead rolling and burr integrated device, which can solve the problems of reduced production efficiency and long workpiece dwell time, and achieves the effects of improving production efficiency, saving labor costs, and accurately positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

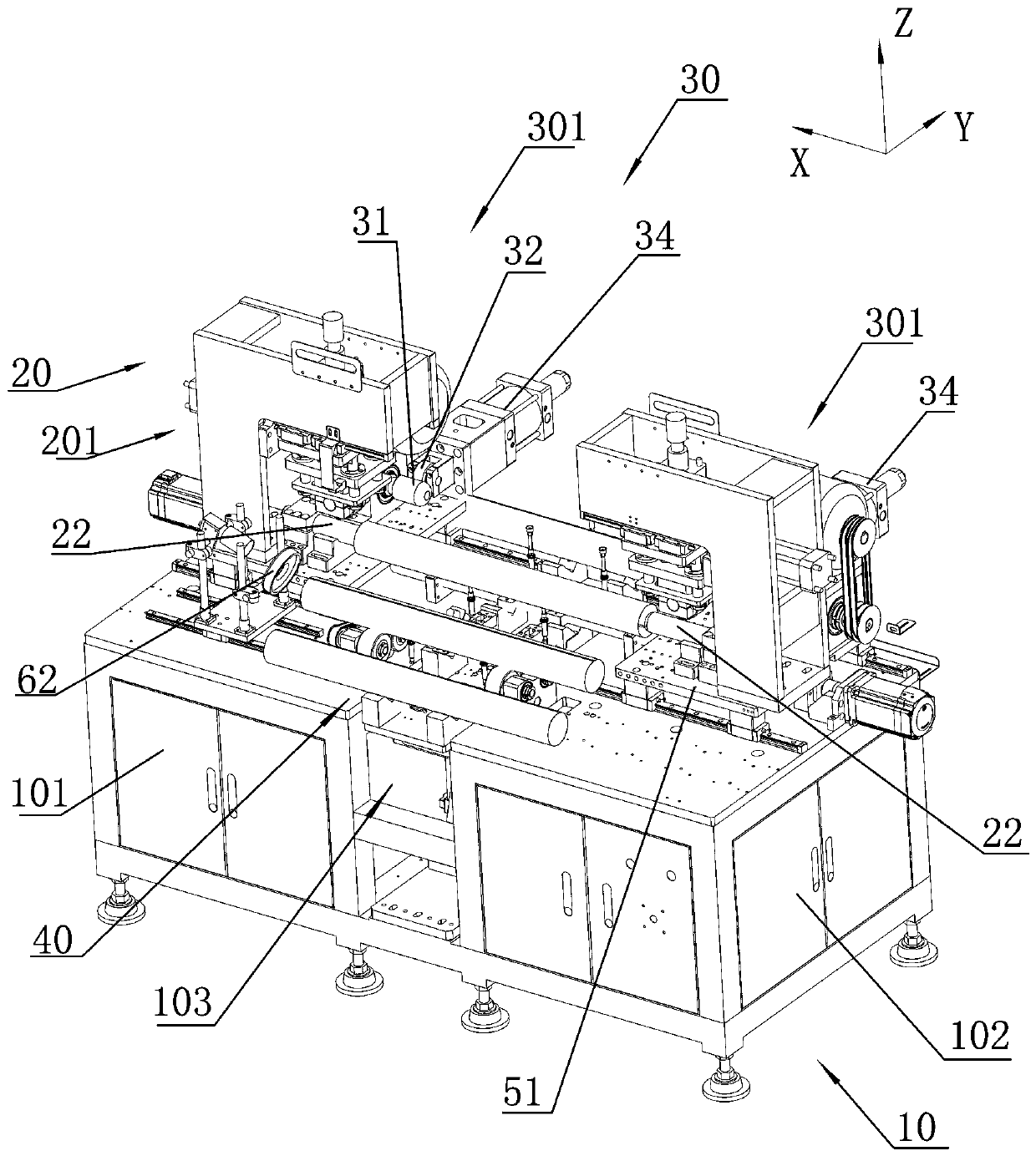

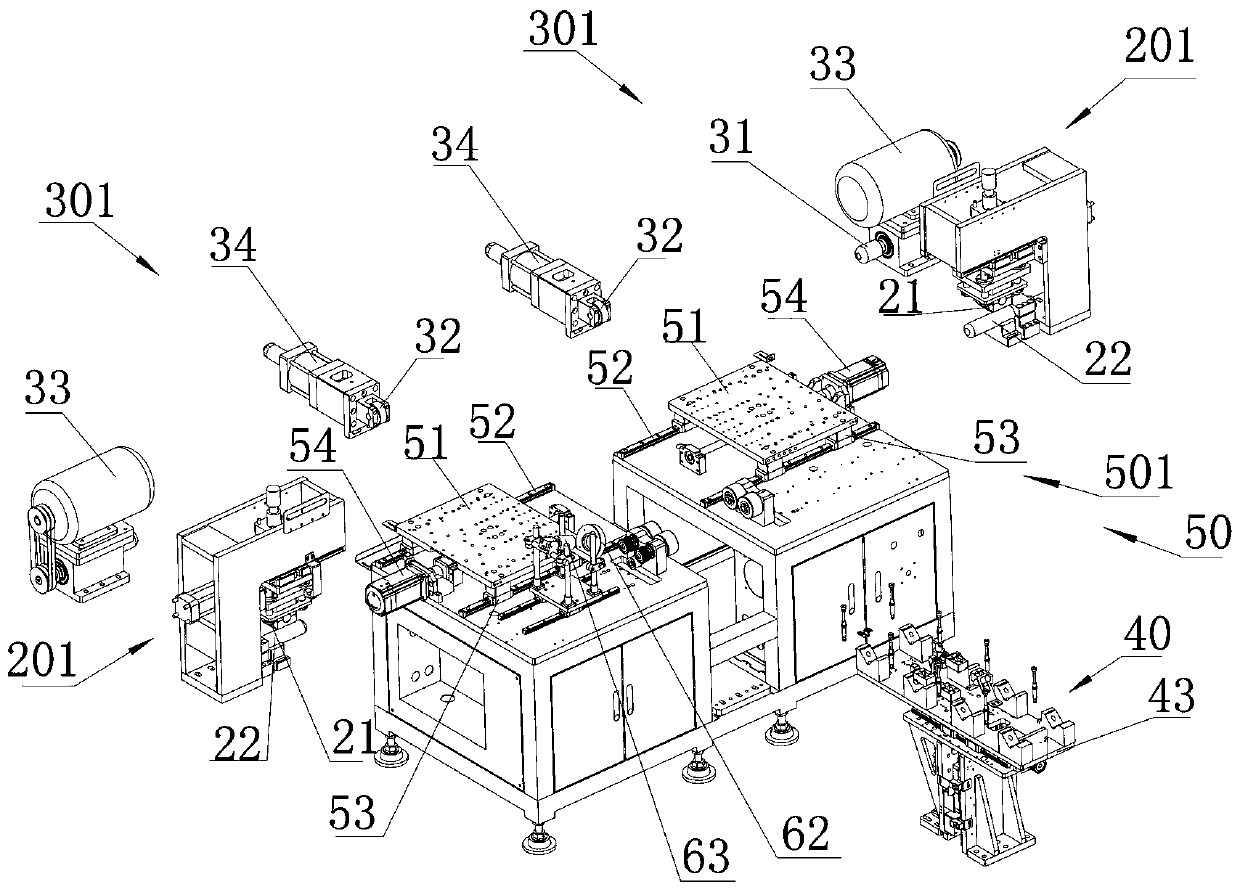

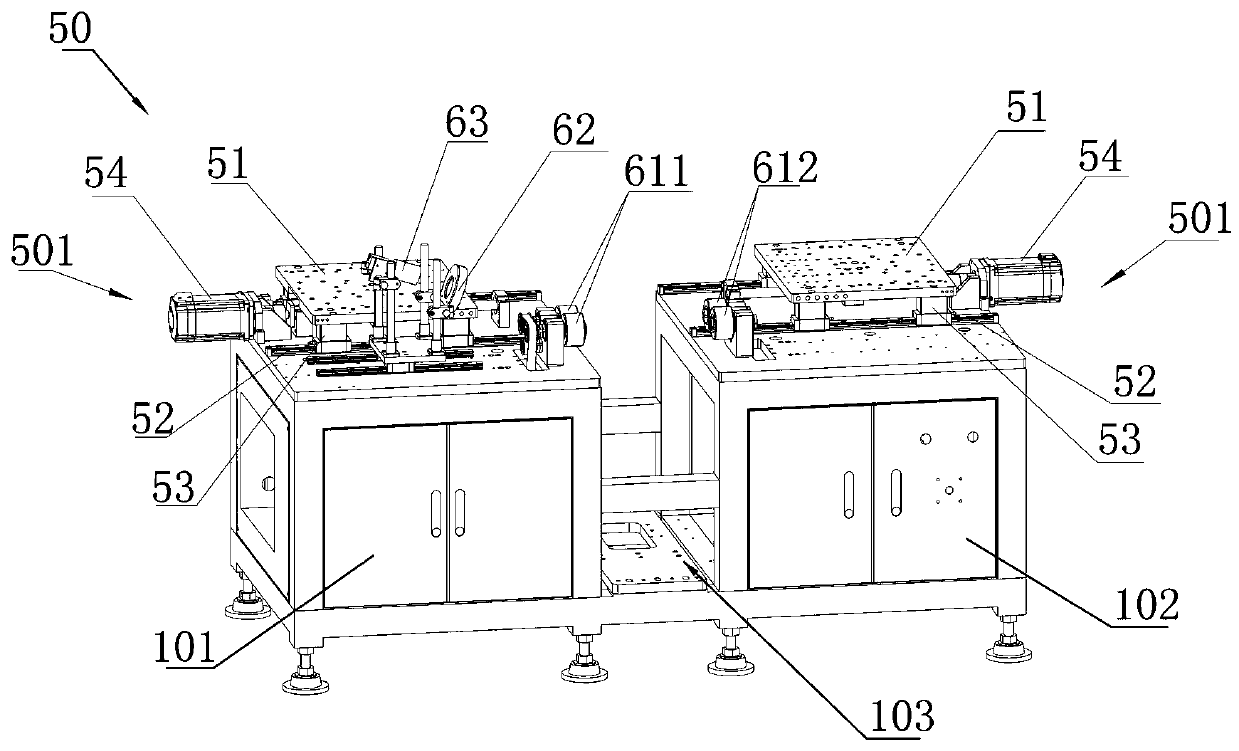

[0025] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

[0026] Figure 1 to Figure 9 , which is a preferred embodiment of the welding bead rolling and burring integrated device provided by the present invention. Such as Figure 1 to Figure 9 As shown, the welding bead rolling and burr integrated device includes a frame 10, and the frame 10 is provided with a welding bead mechanism 20 for rolling the welding bead on the end of the workpiece, and a roller for removing the burrs on the workpiece. The burr mechanism 30 and the transfer mechanism 40 for sequentially transferring the workpiece to the welding bead mechanism and the burr rolling mechanism, the welding bead mechanism 20 includes two oppositely arranged on the frame for welding the end of the workpiece respectively. Pressing the bead welding assembly 201, the burring mechanism 30 includes two burring assemblies 301 oppositely arranged ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap