A garbage transfer device for environmental protection equipment

A technology of environmental protection equipment and transfer device, which is applied in the directions of garbage storage, transportation and packaging, can solve the problems of affecting the work progress, reducing the transfer efficiency, and tedious manual feeding, so as to improve the stability, improve the transfer efficiency, and reduce the down load. the effect of the required time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

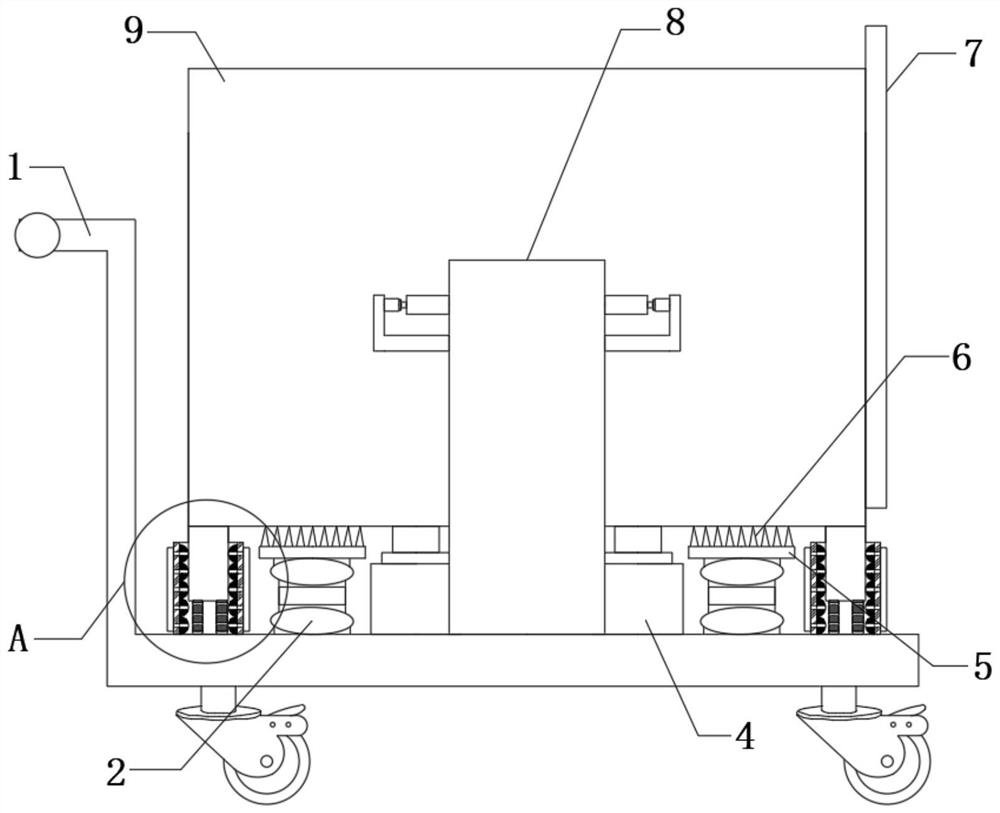

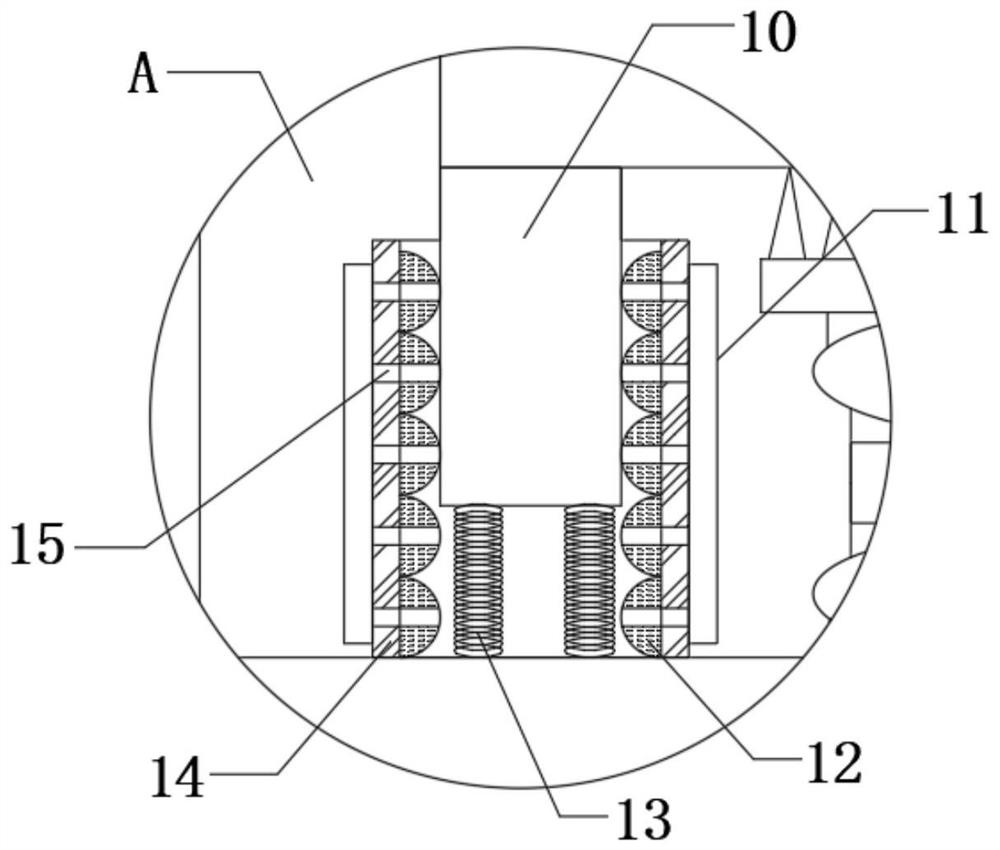

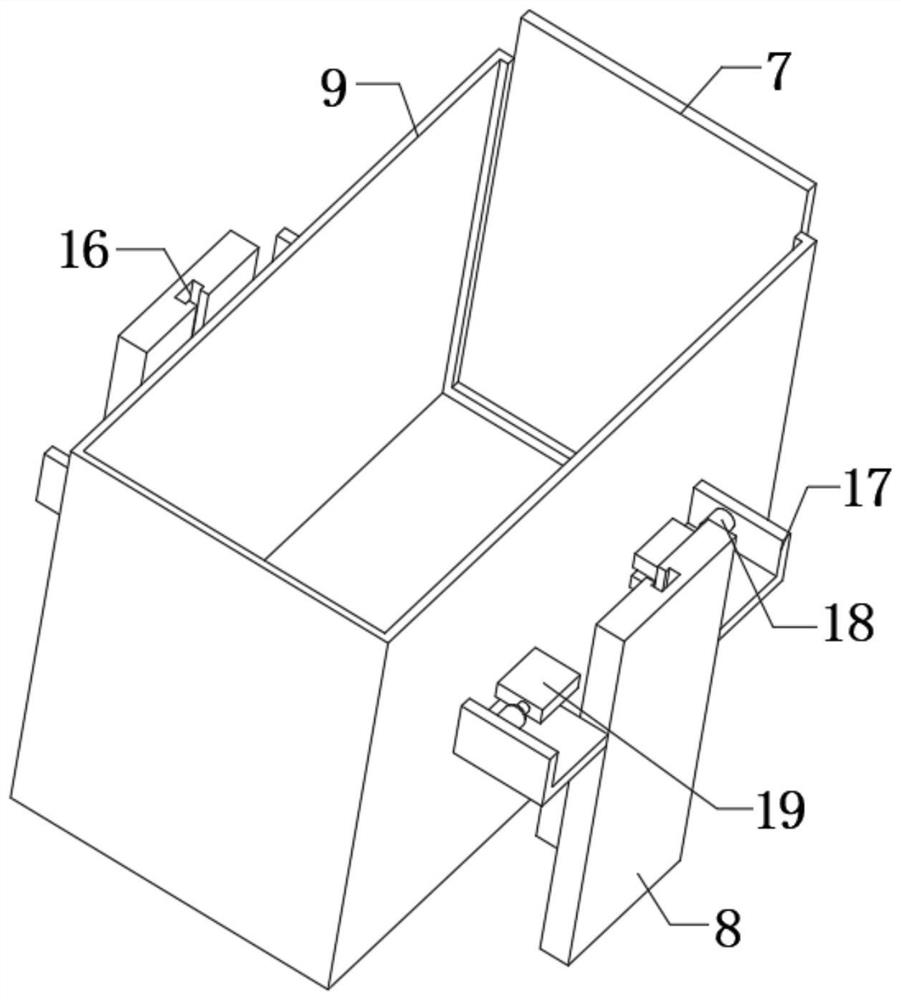

[0027] refer to Figure 1-4 , a garbage transfer device for environmental protection equipment, including a trolley 1 and a limit assembly, the top outer wall of the trolley 1 is fixed with four fixing cylinders 14 by screws, and the inner walls of the four fixing cylinders 14 are all inserted with connecting columns 10 , the top outer walls of the four connecting columns 10 are fixed with the same dustbin 9 by screws, one side of the outer wall of the dustbin 9 is provided with a card slot, the inner wall of the card slot is snapped with a box door 7, and the trolley 1 is located between the two sides of the garbage box 9. The top outer wall of the end is fixed with a fixed plate 8 by screws, and the outer walls of the opposite side of the two fixed plates 8 are all opened with a limit groove 16, and the inner walls of the two limit grooves 16 are all slidably connected with a slide bar 20, and the two slide bars The other ends of 20 are all fixed with side plates 21 by screw...

Embodiment 2

[0036] refer to figure 1 , figure 2 , Figure 5 with Image 6 , a garbage transfer device for environmental protection equipment, including a trolley 1 and a limit assembly, the top outer wall of the trolley 1 is fixed with four fixing cylinders 14 by screws, and the inner walls of the four fixing cylinders 14 are all inserted with connecting columns 10 , the top outer walls of the four connecting columns 10 are fixed with the same dustbin 9 by screws, one side of the outer wall of the dustbin 9 is provided with a card slot, the inner wall of the card slot is snapped with a box door 7, and the trolley 1 is located between the two sides of the garbage box 9. The top outer wall of the end is fixed with a fixed plate 8 by screws, and the outer walls of the opposite side of the two fixed plates 8 are all opened with a limit groove 16, and the inner walls of the two limit grooves 16 are all slidably connected with a slide bar 20, and the two slide bars The other ends of 20 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com