Method for determining flow-back model of shale gas fracturing fluid

A fracturing fluid and shale gas well technology, which is applied in the fields of earthwork drilling, measurement, wellbore/well components, etc., can solve the problems that limit the stable production capacity of shale gas wells, cannot diagnose gas well problems, and cannot determine the productivity of fracturing fluids and gas wells. impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

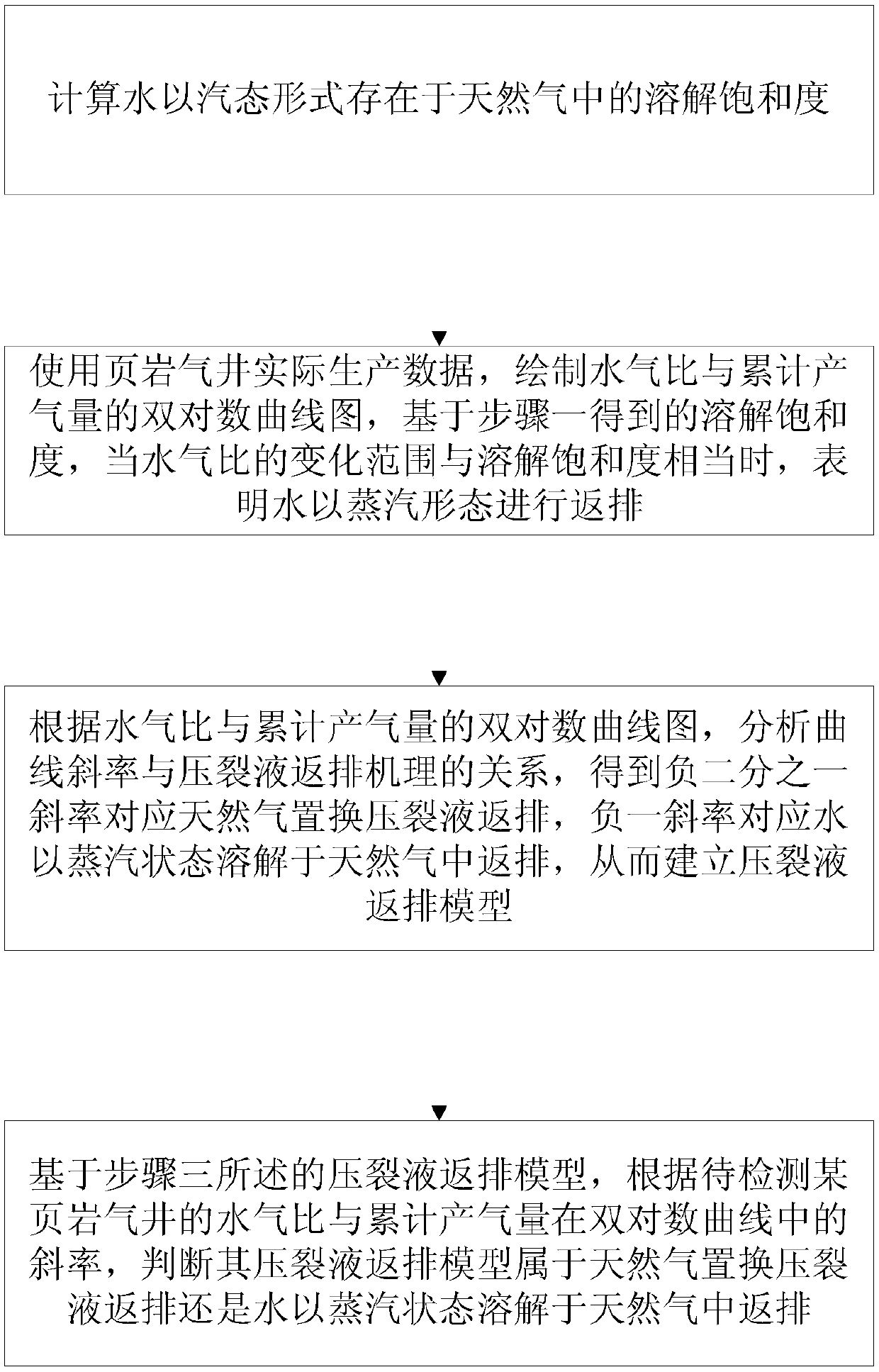

[0028] Such as figure 1 As shown, a method for determining the flowback model of shale gas fracturing fluid includes the following steps:

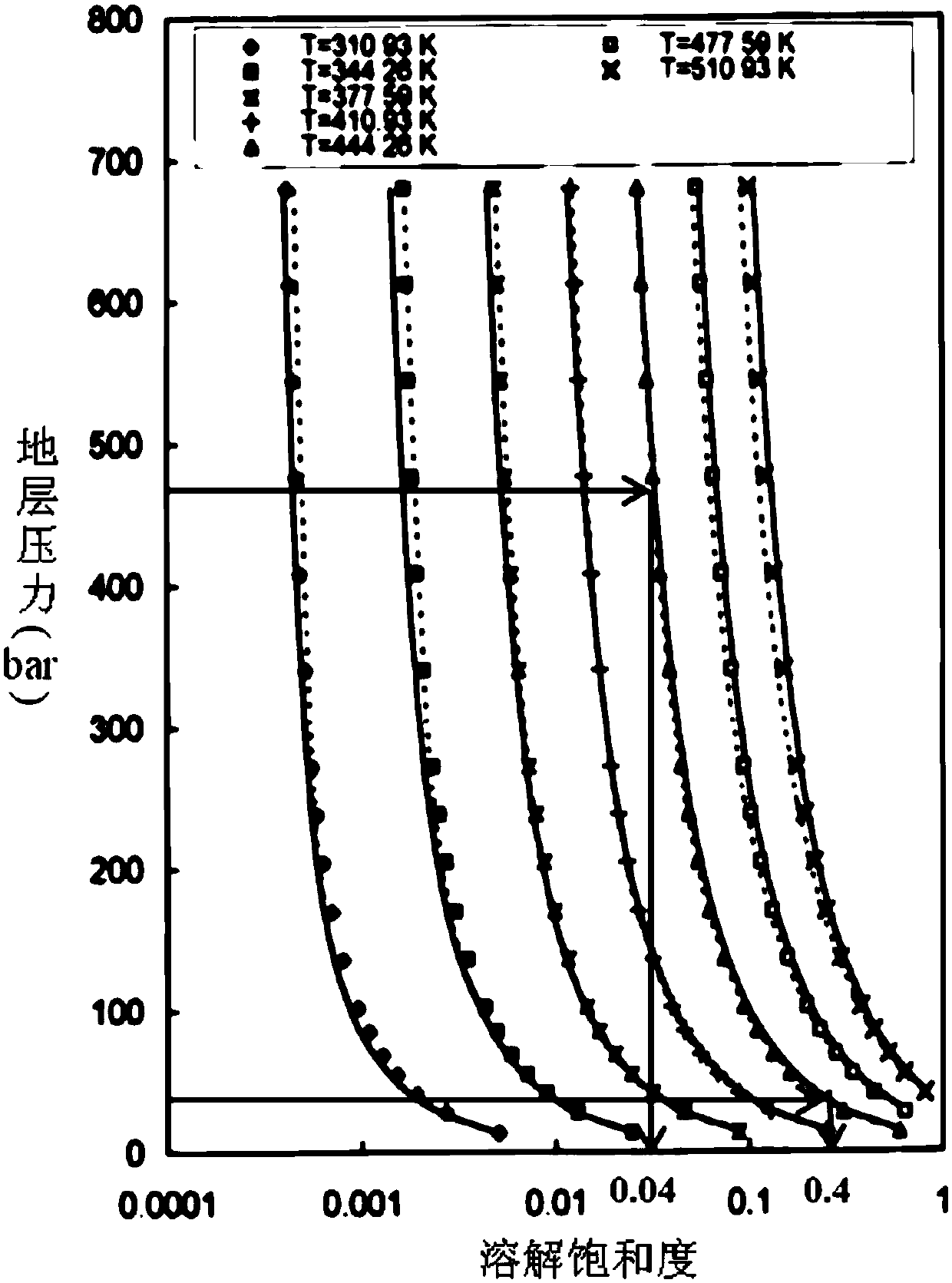

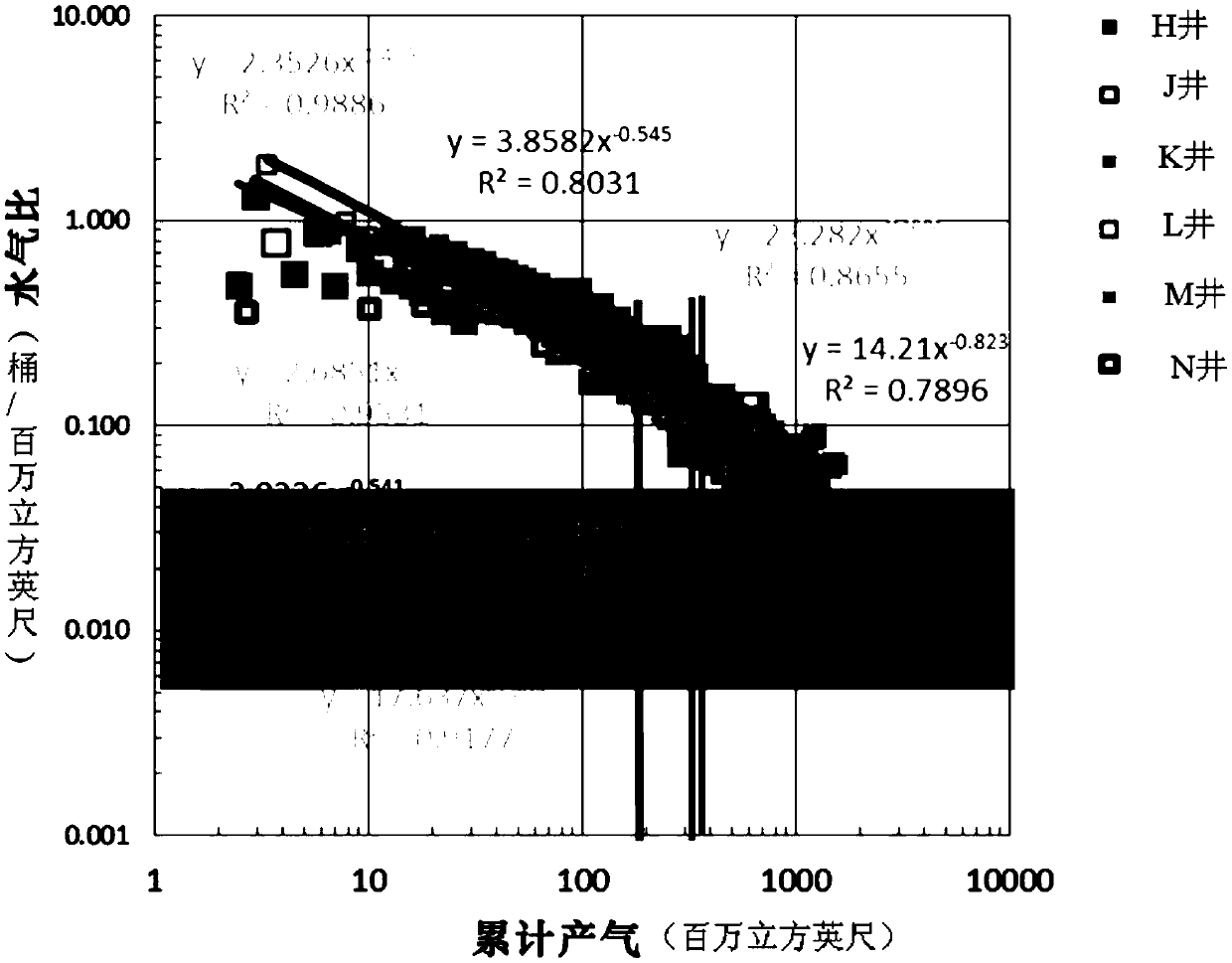

[0029] Step 1: According to formation pressure and temperature, calculate the solubility saturation of water in gaseous form in natural gas. Such as figure 2 As shown, in this example, statistics are made on the Horn River shale gas reservoir, the formation pressure ranges from 313-471bar, the bottomhole flow pressure is 45-70bar, and the formation temperature T=448K, the solution saturation is roughly between 0.04-0.4 between.

[0030] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com