Air conditioner noise testing device and method

A testing device and noise technology, applied in the field of air-conditioning noise testing devices, can solve the problems of inaccurate noise testing results, the inability of the noise testing environment to simulate the real use environment of the air-conditioning, etc., and achieve the effect of accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

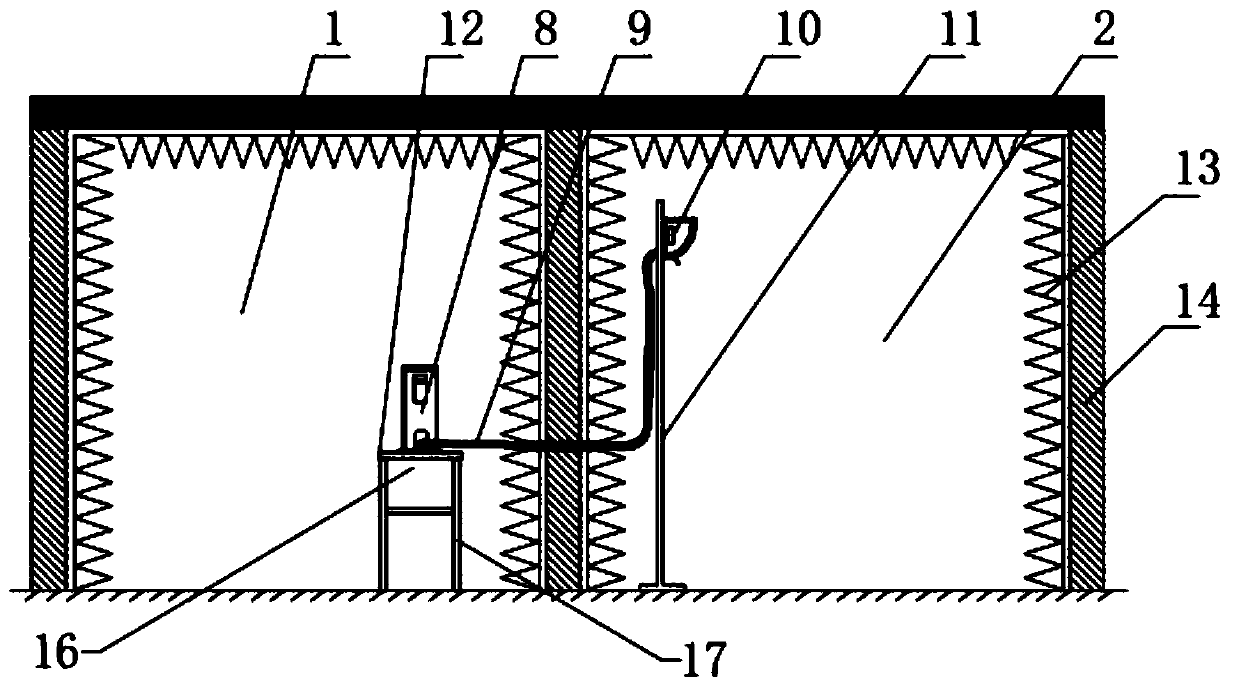

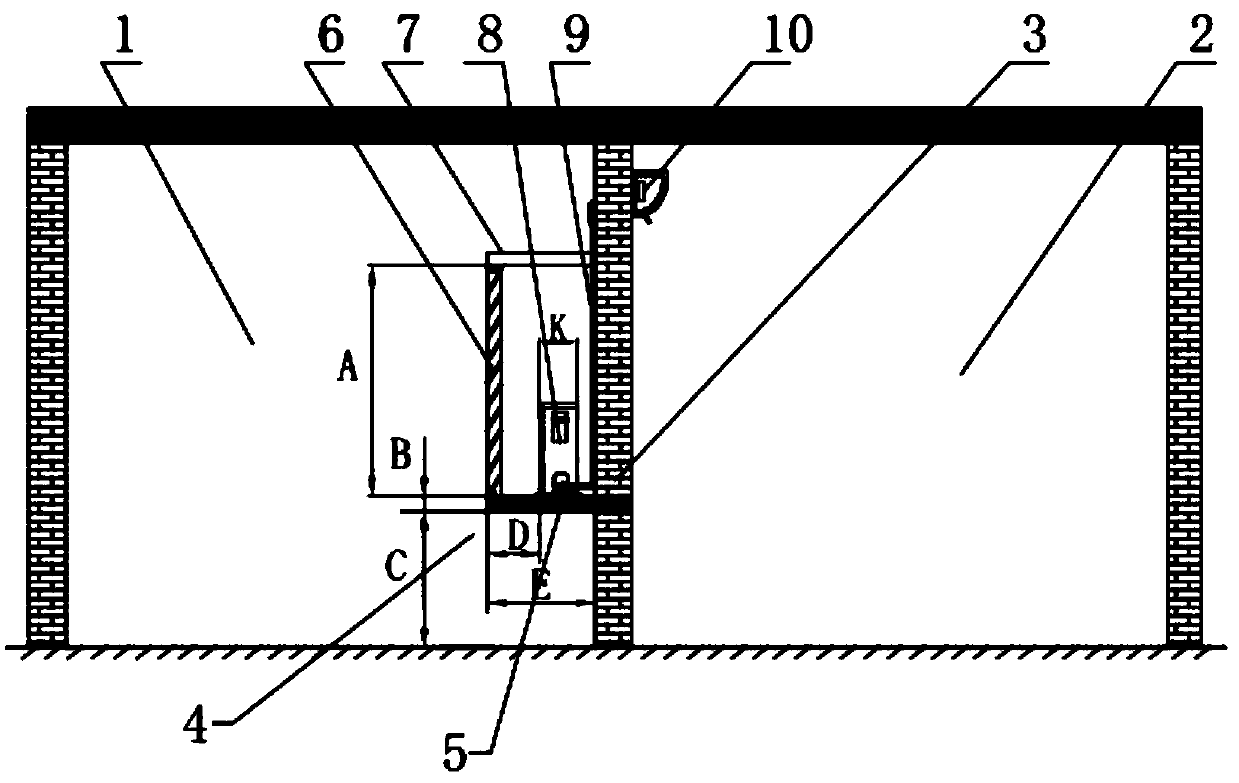

[0039] This embodiment improves the semi-anechoic room noise testing device in the prior art, and provides an air-conditioning noise testing device, such as Figure 3-5 As shown, it includes an outdoor noise room 1, an indoor noise room 2, and a boundary wall 3 arranged between the indoor noise room 2 and the outdoor noise room 1. The outdoor noise room 1 is provided with an external machine installation platform 4, and the external machine The installation platform 4 is connected with the boundary wall 3 between the indoor noise chamber 2 and the outdoor noise chamber 1. When the air conditioner is in use, the external unit installation platform 4 supporting the external unit receives the vibration of the air conditioner external unit, and passes the vibration directly through the The boundary wall 3 is transmitted to the room, so that the boundary wall 3 generates resonance noise. The air conditioner noise test device formed in this embodiment can accurately simulate the real...

Embodiment 2

[0056] Such as Figure 5 As shown, this embodiment provides a method for testing air-conditioning noise on the basis of Embodiment 1, which specifically includes the following steps:

[0057] S1: Put the outdoor unit 8 of the air conditioner on the support platform 5, hang the indoor unit on the boundary wall of the indoor noise room, connect the indoor unit and the outdoor unit with the connecting pipe of the indoor and outdoor unit, pump the vacuum, and open the valve of the outdoor unit;

[0058] S2: Move the platform grille 6 to the front of the outdoor unit, and adjust the distance D between the platform grille 6 and the front of the grille of the outdoor unit according to the standard;

[0059] S3: setting the noise testing device to the first working condition;

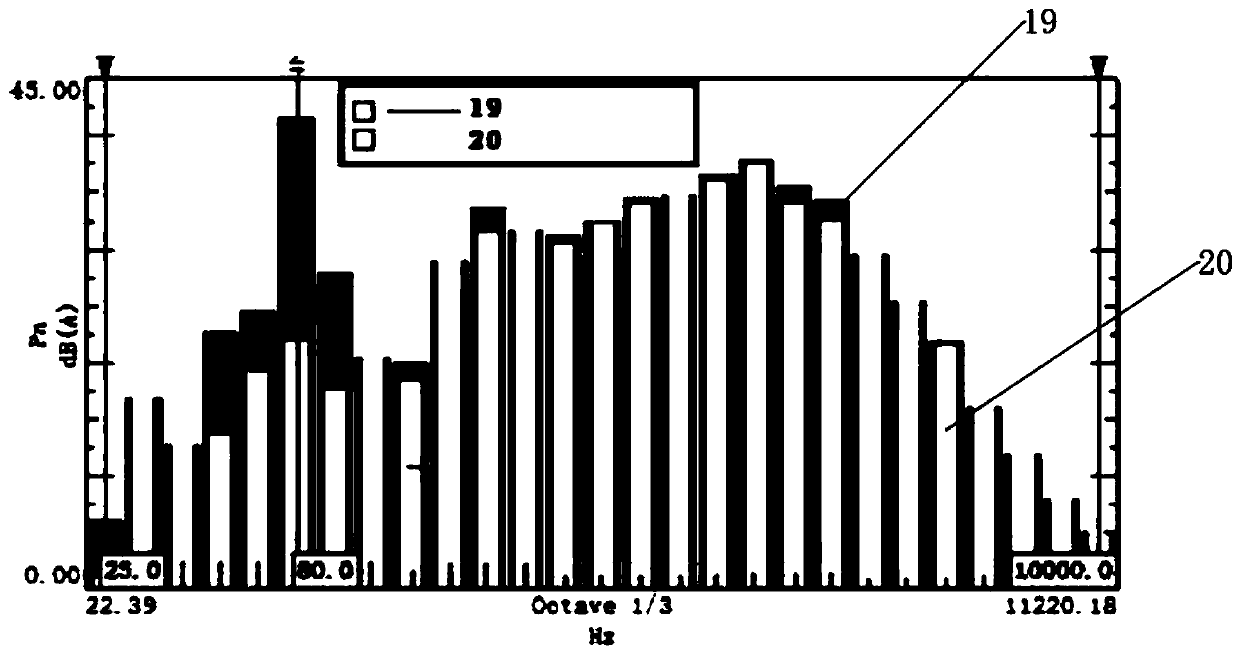

[0060] S4: Turn on the air conditioner and test the noise of the indoor unit and the noise of the outdoor unit. The operating frequency of the air conditioner is measured every 2Hz from 20Hz to 110Hz;

[0061...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com