Pressure wave generating device for low-temperature refrigerator and assembling method of pressure wave generating device

A low-temperature refrigerator and generator technology, applied in refrigerators, refrigeration and liquefaction, machines/engines, etc., can solve problems such as increasing the mass of compressor movers, achieve improved efficiency, good coaxiality, and ensure frictionless movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a pressure wave generating device for cryogenic refrigerators and its assembly method. The pressure wave generating device adopts the double-sided diaphragm spring support mover technology to ensure the gap seal between the piston and the cylinder, and truly realize both. Frictionless movement improves the efficiency of the pressure wave generating device, thereby improving the performance of the cryogenic refrigerator.

[0045] The structure and assembly method of the pressure wave generating device will be described in detail below.

[0046] 1. The structure of the pressure wave generator

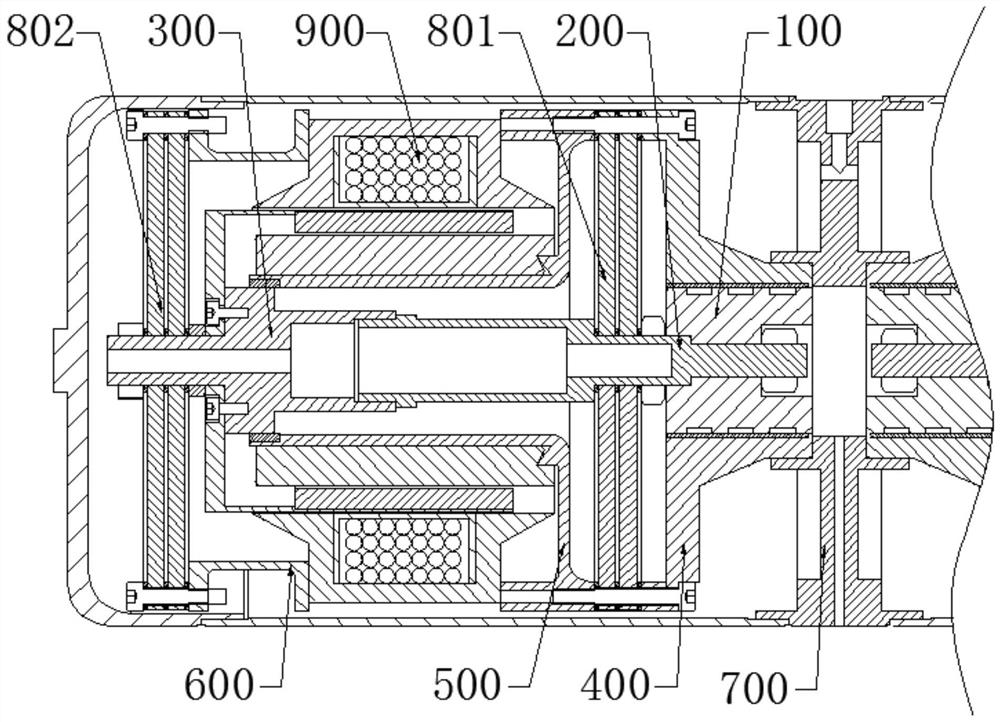

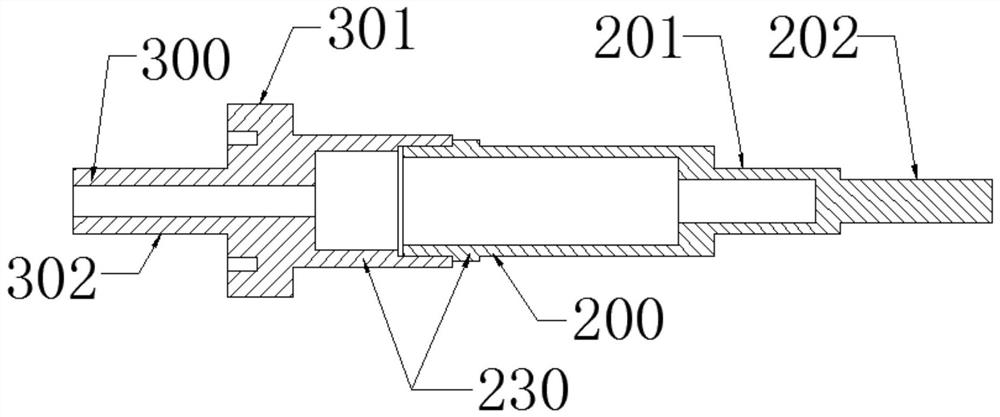

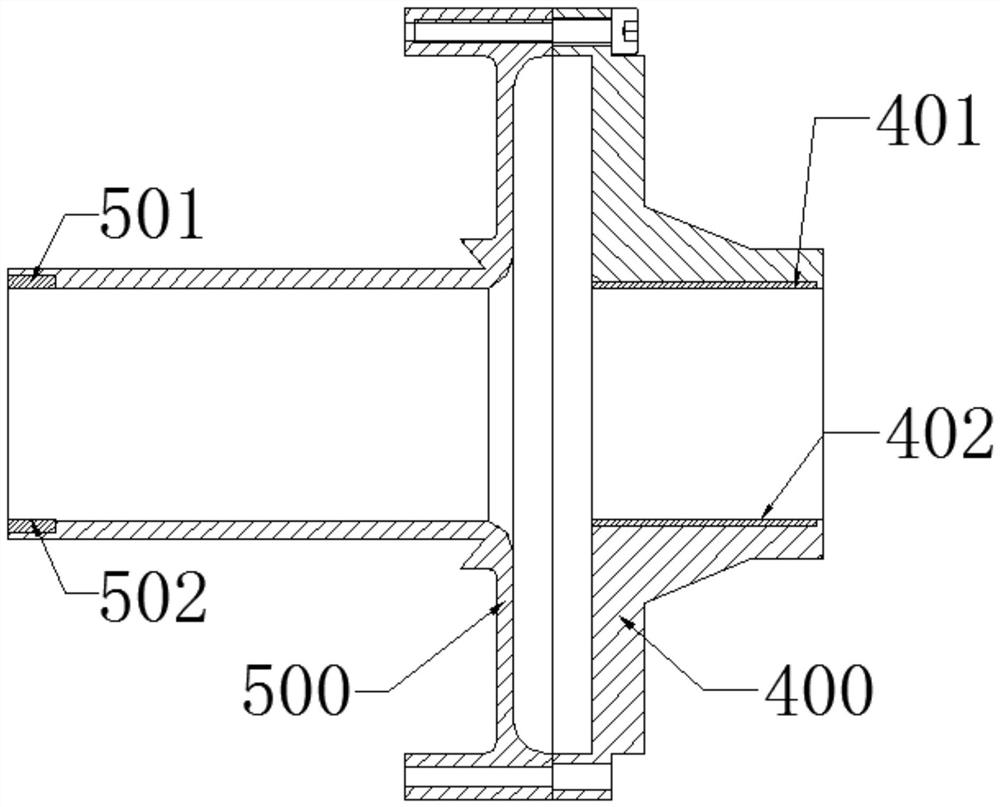

[0047] Such as figure 1 , Figure 8 with Figure 9 As shown, the pressure wave generating device includes a piston head 100, a front piston rod 200, a rear piston rod 300, a front base 400, a rear base 500, a leaf spring seat 600, a main base 700, a front diaphragm spring assembly 801, a rear Diaphragm spring assembly 802, motor assembly 900.

[0048] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com