Ultrasonic atomization and classification device for submicron powder and its application

A sub-micron, atomizing device technology, applied in the direction of swirl device and other directions, can solve the problems of low classification efficiency, complex process, long time consumption, etc., and achieve the effect of improving classification efficiency, energy density, and atomization results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Raw materials to be separated: the particle size range of the original silicon powder is 0-600nm, and the median particle size is 300nm.

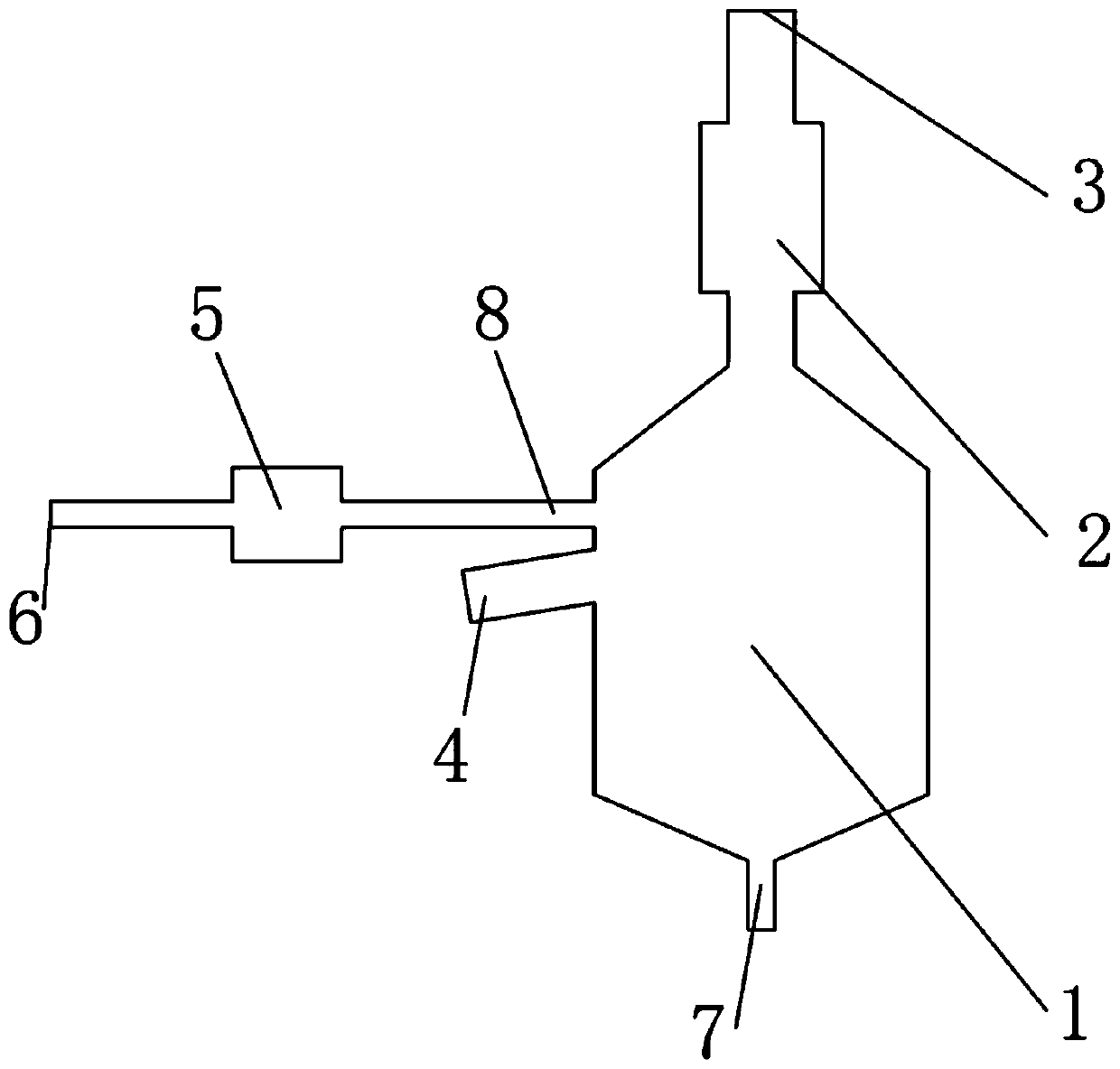

[0086] The height ratio of the upper, middle and lower parts of the ultrasonic atomization device 1 is 6:19:4, the height of the middle part is 0.5m, the diameter is 0.5m, the angle of the upper cone is 35°, and the angle of the lower part is cone, the angle is 20°, and the small hole of the isolation plate 140 is 1, and its diameter is 2cm.

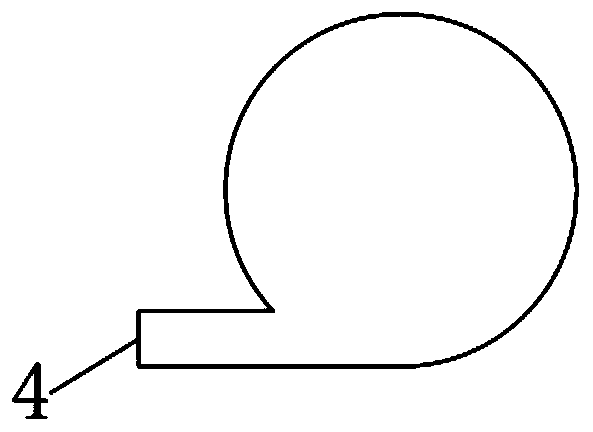

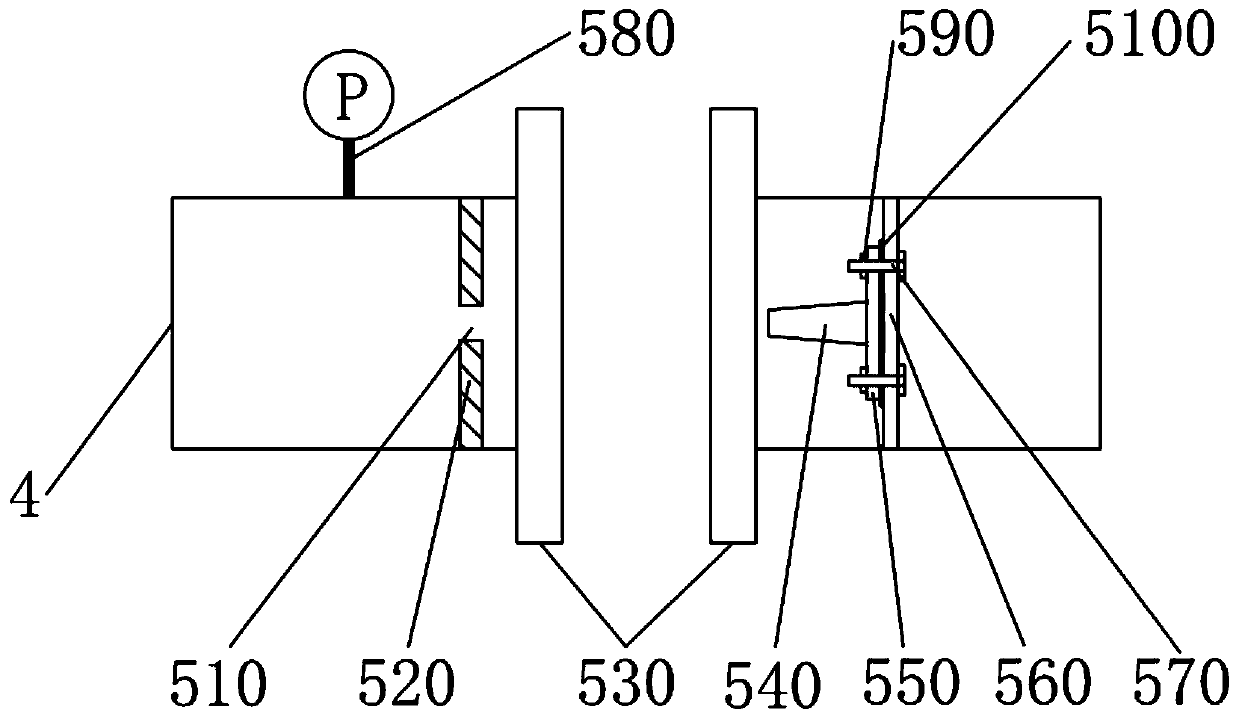

[0087] The above silicon powder to be classified is made into a suspension with a concentration of 0.1%, and the flow rate is 40L / h. The silicon powder suspension is fed from the solution inlet 6, and the inlet water pressure of the solution inlet 6 is 0.5MPa, and the suspension passes through at a high speed. The small hole 510 in the middle of the orifice plate 520 forms a jet and undergoes hydraulic changes. The jet impacts the reed 540. The length and thickness of the reed are 40 and 0.3mm ...

Embodiment 2

[0090] Raw materials to be separated: the particle size range of the original silicon powder is 0-600nm, and the median particle size is 300nm.

[0091] The height ratio of the upper, middle and lower parts of the ultrasonic atomization device 1 is 6:19:4, the height of the middle part is 0.5m, the diameter is 0.5m, the angle of the upper cone is 35°, and the angle of the lower part is cone, the angle is 20°, and the small hole of the isolation plate 140 is 1, and its diameter is 2cm.

[0092] The above-mentioned silicon powder to be classified is made into a suspension with a concentration of 0.1%, and the flow rate is 40L / min. The silicon powder suspension is sent from the solution inlet 6. The inlet water pressure of the solution inlet 6 is 0.3MPa, and the suspension passes through at a high speed. The small hole 510 in the middle of the orifice plate 520 forms a jet and undergoes hydraulic changes. The jet impacts the reed 540. The length and thickness of the reed are 40 a...

Embodiment 3

[0095] Raw materials to be separated: the particle size range of the original silicon powder is 0-600nm, and the median particle size is 300nm.

[0096] The height ratio of the upper, middle and lower parts of the ultrasonic atomization device 1 is 6:19:4, the height of the middle part is 0.5m, the diameter is 0.5m, the angle of the upper cone is 35°, and the angle of the lower part is cone, the angle is 20°, and the small hole of the isolation plate 140 is 1, and its diameter is 2cm.

[0097] The above silicon powder to be classified is made into a suspension with a concentration of 0.3%, and the flow rate is 40L / h. The silicon powder suspension is fed from the solution inlet 6, and the inlet water pressure of the solution inlet 6 is 0.5MPa, and the suspension passes through at a high speed. The small hole 510 in the middle of the orifice plate 520 forms a jet and undergoes hydraulic changes. The jet impacts the reed 540. The length and thickness of the reed are 40 and 0.3mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com