A six-dimensional piezoelectric vibration energy harvester

An energy harvester and electric vibration technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as dead spots, component wear, and large energy consumption , to achieve the effects of reasonable structure setting, easy processing and assembly, and high energy collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

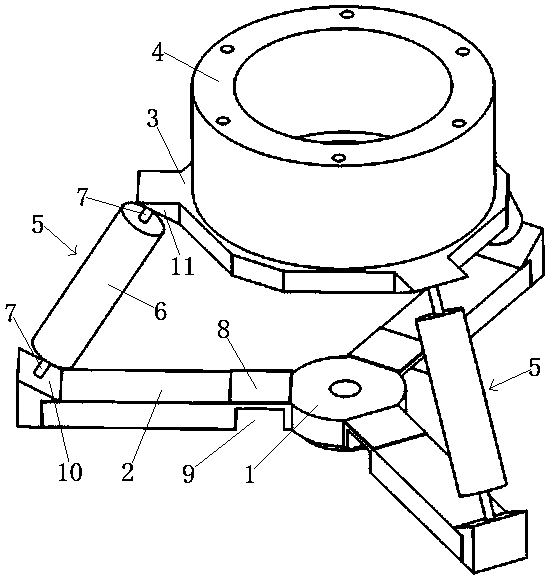

[0025] Such as figure 1 A six-dimensional piezoelectric vibration energy harvester shown includes a base 1, a plurality of flexible beams 2, a plurality of outrigger assemblies 5 and an inertial mass set above the base 1, the base 1 and the inertial mass There are gaps between them, the multiple flexible beams 2 are distributed in a circular array, and the multiple outrigger assemblies 5 correspond to the multiple flexible beams 2 one by one; the flexible beams 2 are elongated structures, and the roots of the multiple flexible beams 2 are all fixedly connected On the base 1 to form a cantilever beam structure, the free ends of multiple flexible beams 2 are fixedly connected to one end of multiple outrigger assemblies 5, and the other ends of multiple outrigger assemblies 5 are fixedly connected to inertial mass components, each There is an included angle between the outrigger assembly 5 and the flexible beam 2 connected thereto; in order to transfer the vibration of the inerti...

Embodiment 2

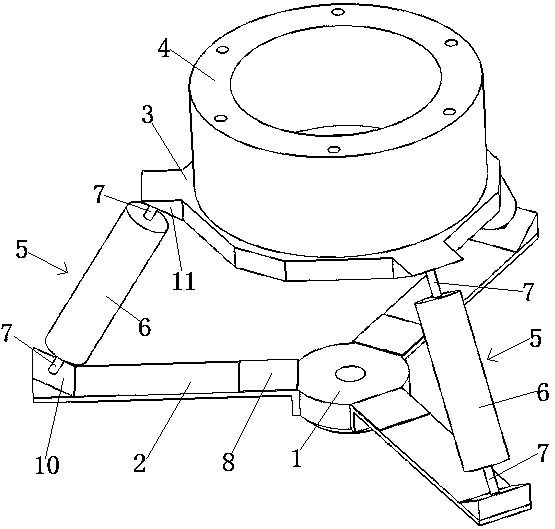

[0033] Such as figure 2 As shown, the difference between the second embodiment and the first embodiment is that the flexible beam 2 in the second embodiment is a thin plate-shaped elongated structure, and the flexible beam 2 of this structure can also be placed in the The roots undergo a relatively large mechanical deformation.

Embodiment 3

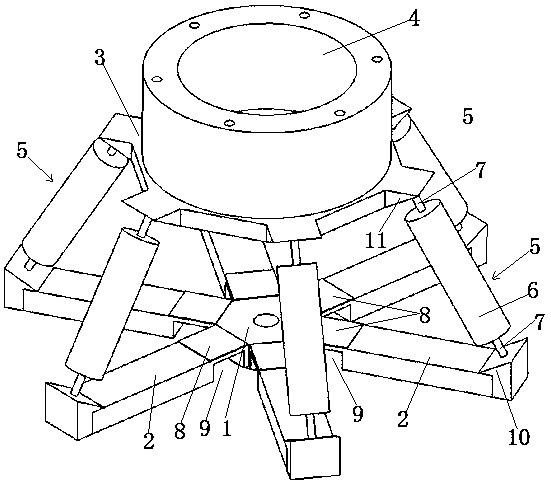

[0035] Such as image 3 As shown, the difference between the third embodiment and the first embodiment is that six flexible beams 2 are fixedly connected to the base 1 in the third embodiment, and the angle between two adjacent flexible beams 2 is 60 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com