Working pressure testing device for small gas generator

A gas generator and working pressure technology, which is applied in the direction of measuring devices, testing of machines/structural components, instruments, etc., can solve the problems that cannot reflect the actual performance level of the product to be delivered, cannot test the working pressure, and the structural space is limited. Achieve the effect of light weight, simple structure and high characterization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained and illustrated below in conjunction with the accompanying drawings and specific embodiments.

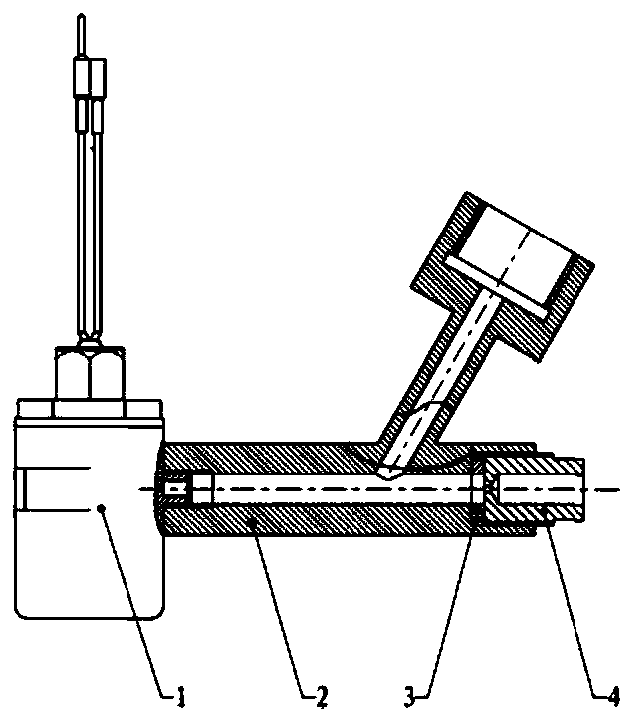

[0024] A working pressure test device for a small gas generator 1, comprising a gas generator 1, a three-way pipeline 2, a secondary nozzle 4, a copper pad 3 and a ground generator 5. The ground generator 5 is mainly used to determine the relationship between the internal pressure of the three-way pipeline 2 and the internal pressure of the gas generator 1 . When the gas generator 1 is working, the high-temperature gas flows into the three-way pipeline 2, and then is discharged through the secondary nozzle 4. Due to the action of the secondary nozzle 4, a certain pressure is formed in the test pipeline, and the three-way pipeline can be measured. 2 internal pressure, and finally use the relationship between the internal pressure of the three-way pipeline 2 and the internal pressure of the gas generator 1 to indirectly obtain the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap