Filter

A filter and filter element technology, which is applied to fixed filter element filters, filtration separation, and filtration circuits, can solve the problems of mixing raw material liquid and filtrate, complex structure, and the inability of the filter to realize upstream and downstream exhaust at the same time, to achieve Good exhaust effect, simple exhaust structure, and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

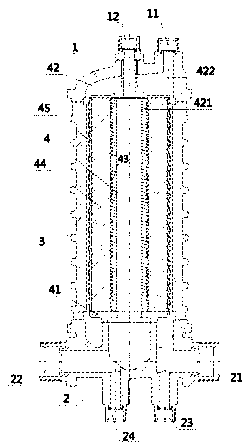

[0026] A filter includes an upper shell 1, a lower shell 2, a cylinder body 3 and a filter element 4, the upper shell 1 and the lower shell 2 are respectively welded to the upper end and the lower end of the cylinder body 3, and the filter element 4 is fixed inside the cylinder body 3.

[0027] The upper shell 1 includes an upstream exhaust port 11, a downstream exhaust port 12 and a central circular hole 13, wherein the upstream exhaust port 11 and the central circular hole 13 are formed integrally with the upper shell 1 by injection molding, and the upstream exhaust port 11 is located on the upper shell 1 The edge of the downstream exhaust port 12 is welded to the center hole 13.

[0028] The upstream exhaust port 11 is in fluid communication with the space between the outer periphery of the filter element 4 and the inner wall of the cylinder 3 .

[0029] The lower shell 2 includes an inlet 21 , an outlet 22 , an upstream drain 23 and a downstream drain 24 , and the inlet 21...

Embodiment 2

[0038] The filter provided by the present invention is used upside down, and when the upside down filter is fixed in the pipeline, the upstream and downstream exhaust and the upstream and downstream liquid discharge can also be realized simultaneously.

[0039] When the filter is used upside down, the figure 1 The upstream liquid outlet 23 in the middle plays the role of upstream exhaust, the downstream liquid outlet 24 plays the role of downstream exhaust, the upstream exhaust port 11 plays the role of upstream liquid discharge, and the downstream exhaust port 12 plays the role of downstream exhaust The role of liquid.

[0040] When filtering, at first the upstream exhaust port 11 and the downstream exhaust port 12 on the upper shell 1 at the lower end of the filter are sealed with a nut, and the fluid flows into the outer periphery of the filter element 4 from the inlet 21 of the lower shell 2 at the upper end of the filter. In the space between the inner walls of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com