A yarn flocking mechanism integrating flocking drying and removing excess velvet

An all-in-one, flocking technology, applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problems of easy pollution, waste of time, uneven distribution of fluff on the surface of the yarn, etc. The flocking efficiency is enhanced, the time is reduced, and the flocking effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

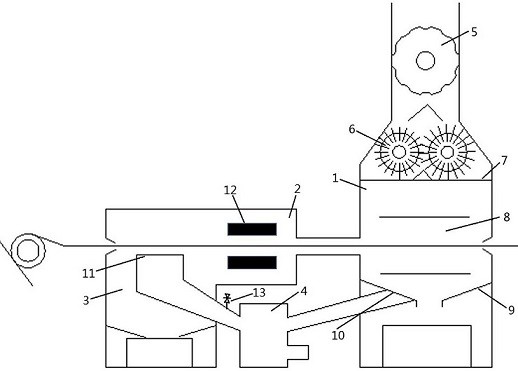

[0016] like figure 1 As shown, a yarn flocking mechanism integrated with flocking, drying, and lint removal includes a flocking area 1, a drying area 2, a lint removal area 3 and a vortex tube 4, and the flocking area includes feeding Roller 5, separating drum 6, screen 7, flocking chamber 8 and flocking hopper 9, the cold air outlet 10 of the vortex tube 4 is located on the flocking hopper 9, and blows the excess fluff that falls into the flocking chamber 8 again , so that the fluff in the flocking chamber 8 flutters and disperses evenly; the hot air outlet 11 of the vortex tube 4 is parallel to the yarn in the lint removal area 3, blowing off the lint on the surface of the yarn and further curing the glue.

[0017] The drying area 2 includes two far-infrared light sources 12 arranged in parallel, respectively located on the upper and lower sides of the yarn.

[0018] A temperature regulating valve 13 is provided at the end of the hot gas outlet 11 of the vortex tube 4, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com