Patents

Literature

33results about How to "Good flocking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

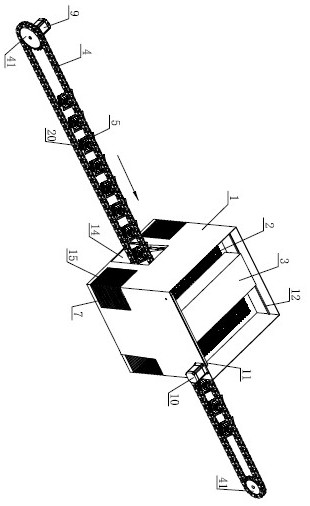

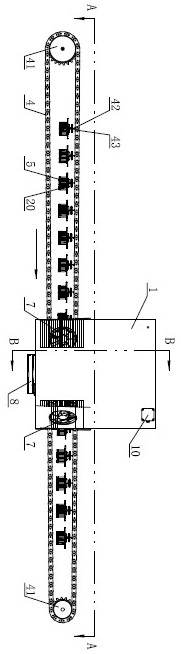

Electrostatic flocking process and device

InactiveCN103846205AReduce labor intensityImprove efficiencyPretreated surfacesElectrostatic spraying apparatusBiochemical engineeringAir purification

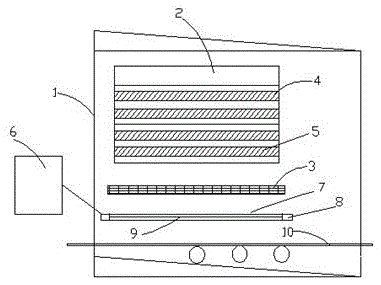

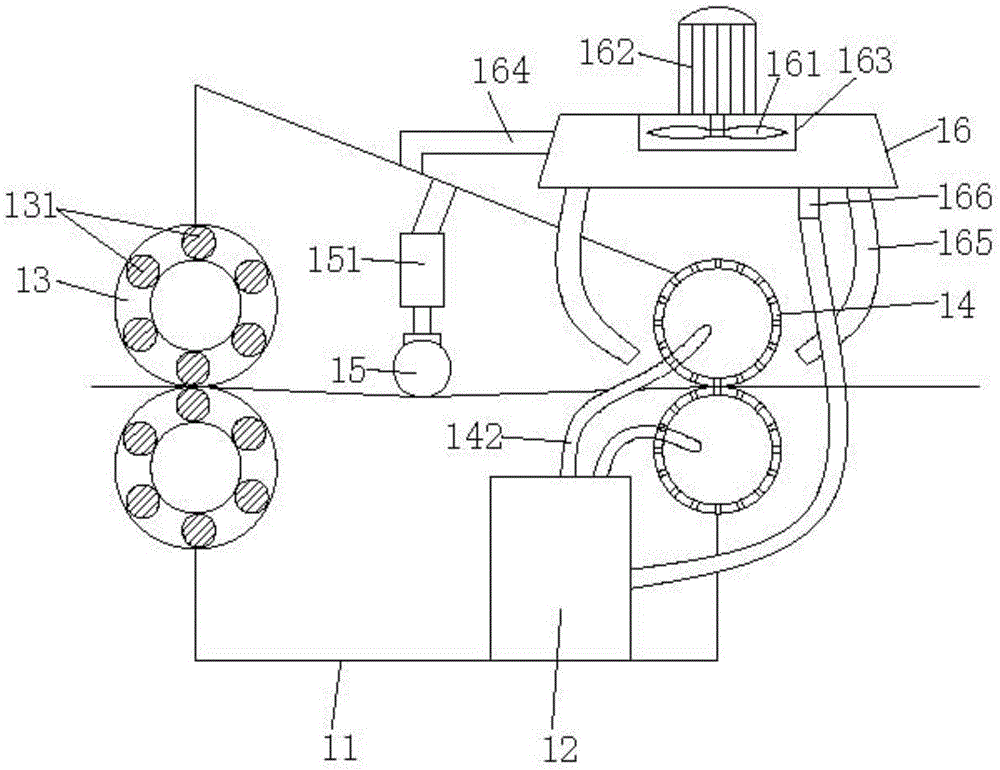

The invention discloses an electrostatic flocking process and an electrostatic flocking device for the electrostatic flocking process. The electrostatic flocking device comprises a pre-coating device, a coloring device and a flocking device, wherein a four-wheel deviation rectification structure is arranged on the front part of the flocking device, and a falling flock cleaning structure is arranged on the rear part of the flocking device. The electrostatic flocking device is simple and delicate in structure, and has good flocking effects; the electrostatic flocking process and the electrostatic flocking device can be used for realizing chromatic flocking and automatic flocking, so that high flocking efficiency is ensured, and the labor intensity is reduced; an obtained product is aging-resistant, abrasion-resistant and free of flock falling, and has sound absorption and dust absorption air purification functions.

Owner:孙有峰

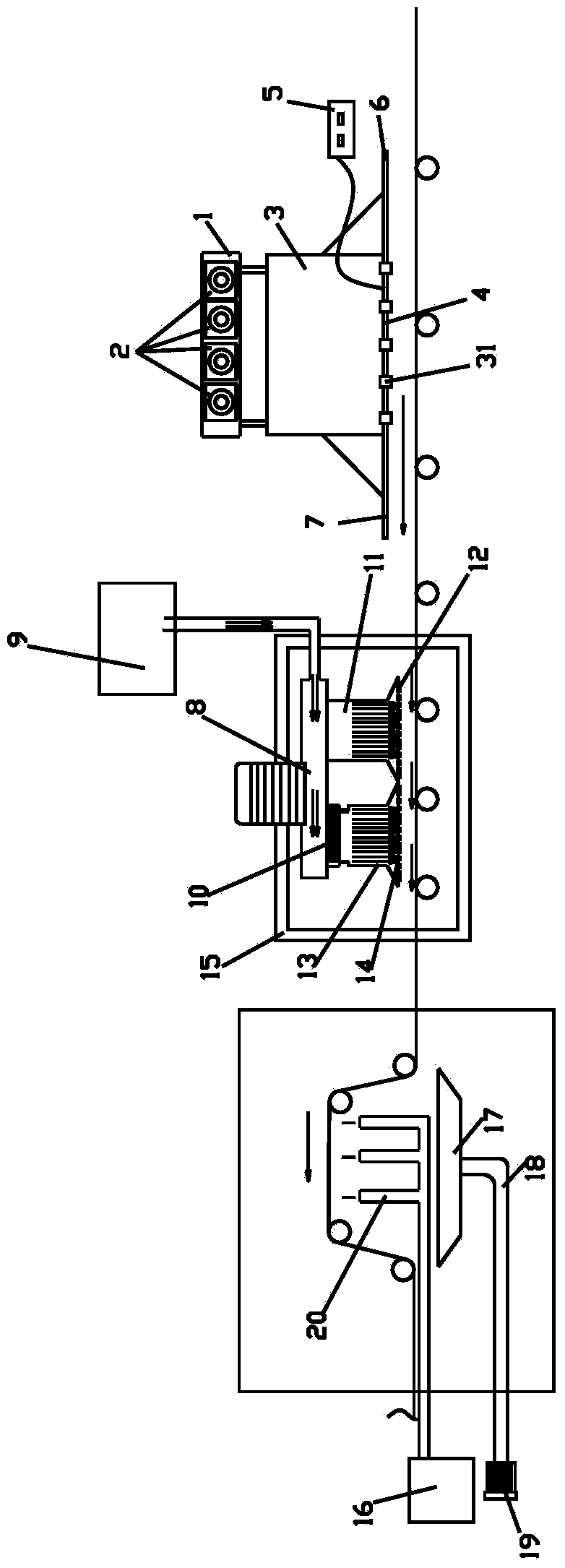

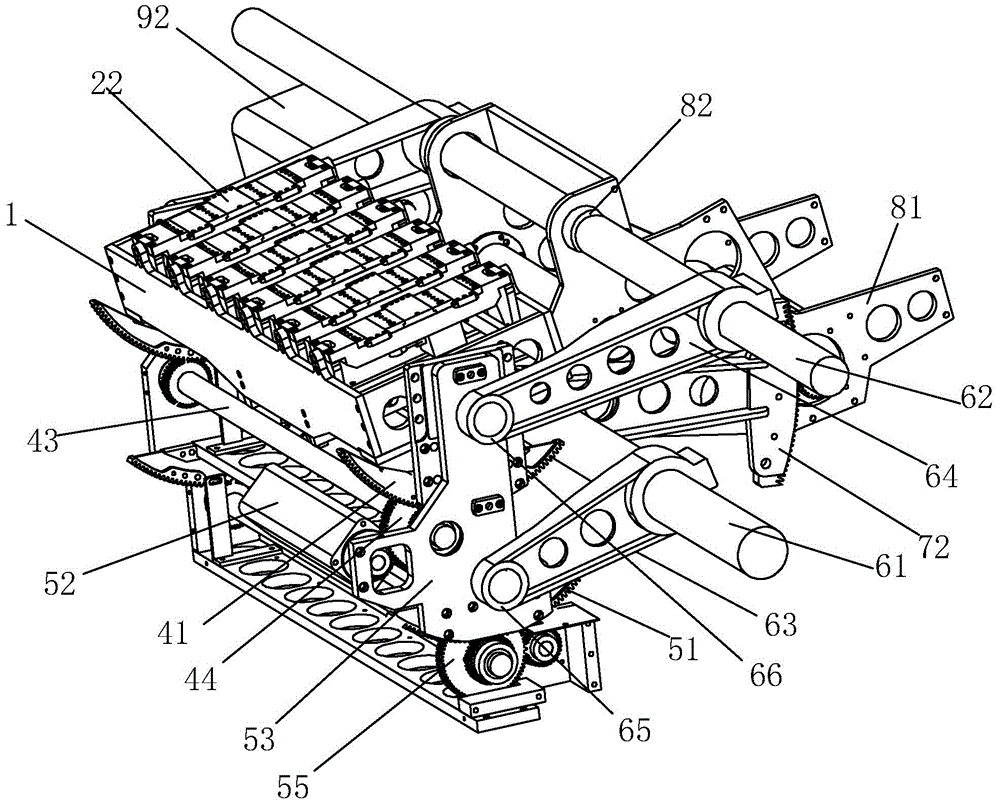

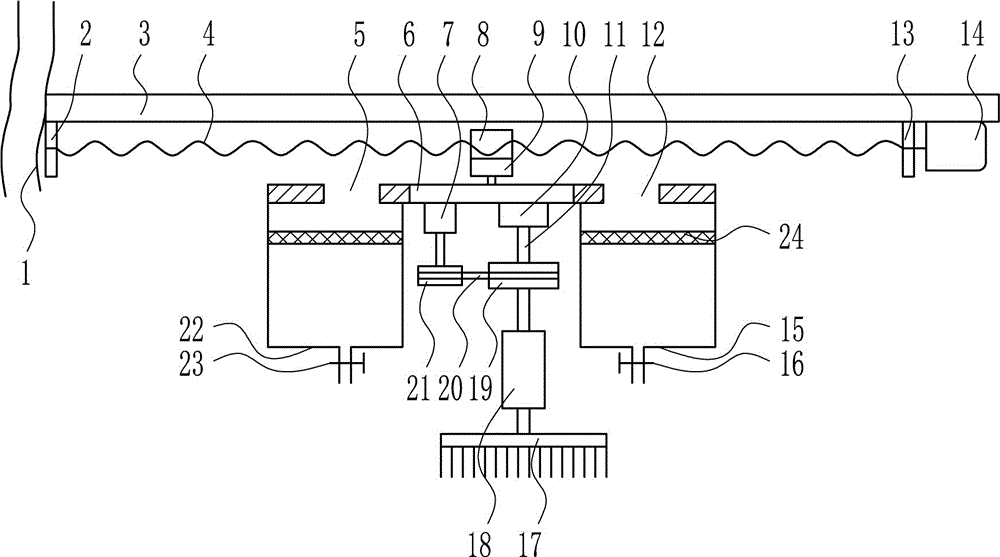

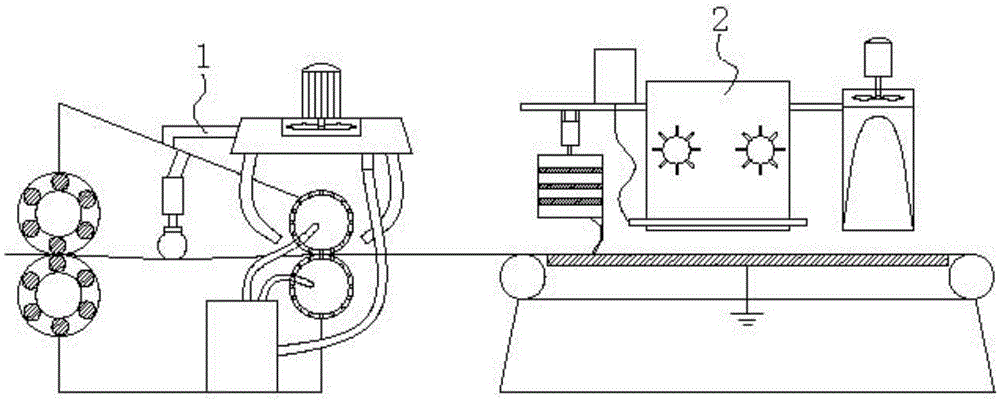

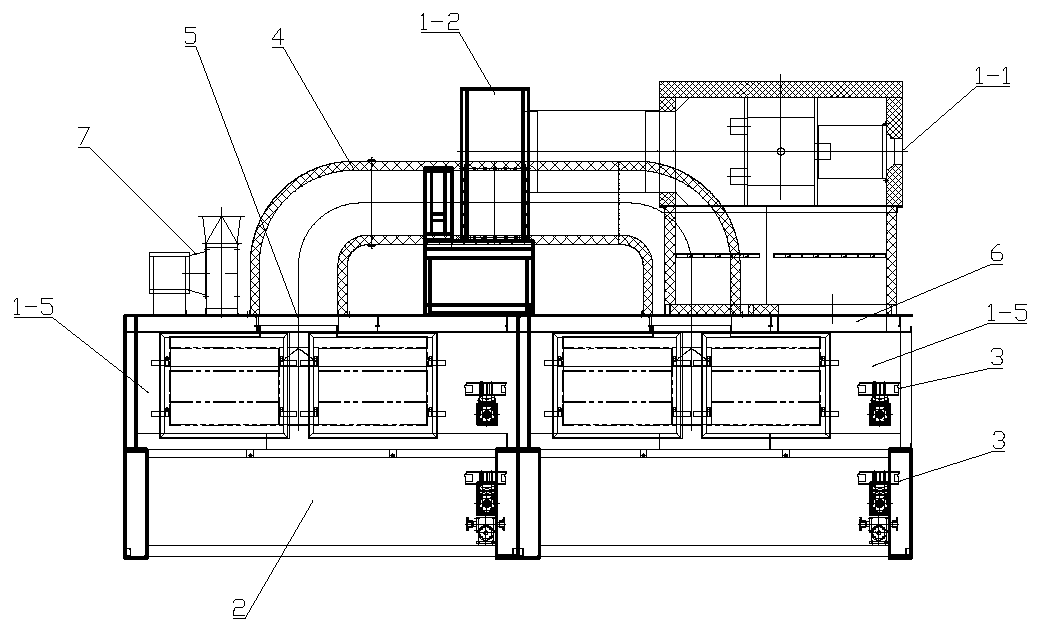

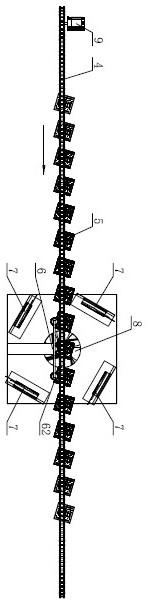

Mechanical flocking plant

InactiveCN103521405AIncrease productivityImprove product qualityLiquid spraying plantsLiquid surface applicatorsProduction lineDrive motor

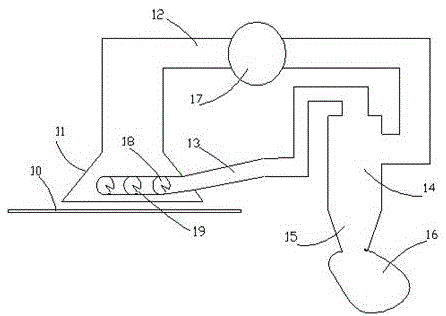

The invention relates to a mechanical flocking plant and belongs to the technical field of flocking machines. The mechanical flocking plant comprises a supporting frame, a faller, a flocking device, a baking device and a cleaning device. The supporting frame is provided with a circulation conveyor belt, the faller is fixedly arranged on the conveyor belt and simultaneously moves along with the conveyor belt, and the flocking device, the baking device and the cleaning device are arranged on the conveyor belt of the supporting frame in sequence. Drive motors are arranged at the two ends of the conveyor belt respectively and drive the conveyor belt to rotate. The whole processes from electrostatic flocking and drying to fluff removing are operated in a full automation mode, production efficiency and product quality of prints are greatly improved, besides, management of a production line is facilitated, and the purpose of protecting the environment is achieved.

Owner:JIASHAN YIXIN FLOCKING

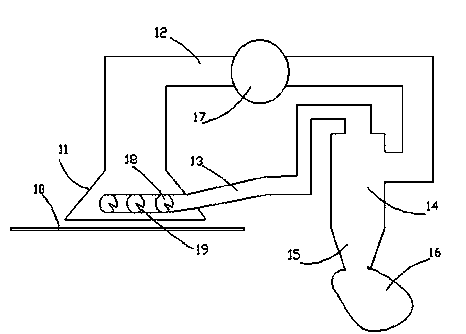

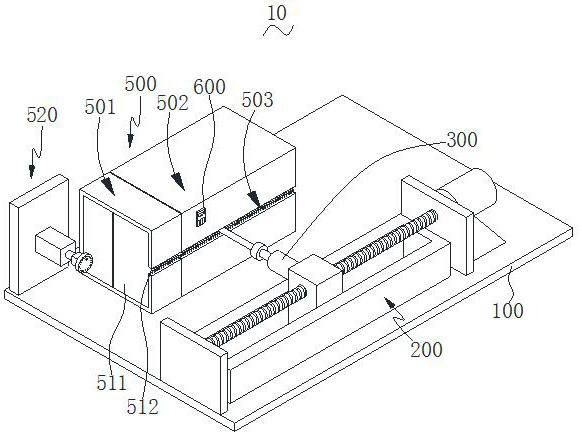

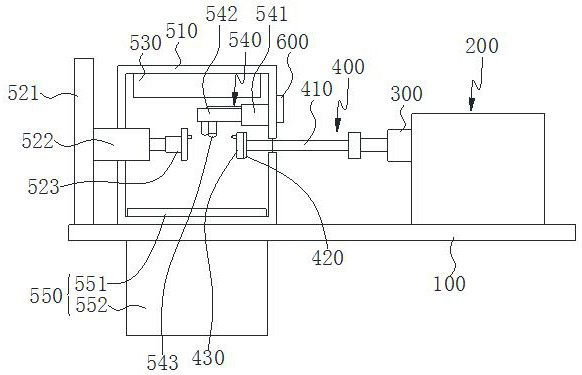

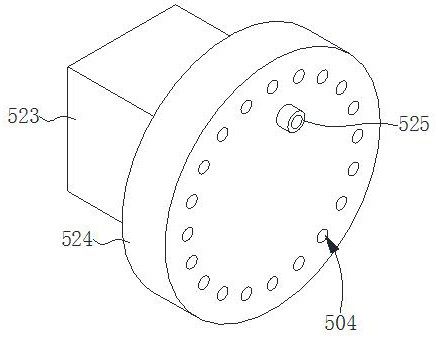

High-reliability sampling swab flocking processing device

InactiveCN113814140AWind evenlyAdhesion is uniform and tightPretreated surfacesCoatingsPosition sensorControl theory

The invention provides a high-reliability sampling swab flocking processing device. Positioning is conducted through a light position sensor, and through cooperation of a horizontal driving mechanism and a rotary driving mechanism, each power generation hole is arranged coaxial with a corresponding fixed insertion hole; and telescopic equipment drives an electrostatic generator to move close to a bearing disc, so that a sampling head of each sampling swab to be flocked is correspondingly inserted into one power generation hole, and the power generation head in each power generation hole uniformly applies static electricity to the sampling heads of the sampling swabs to be flocked. After the static electricity is applied, an electric access door and an electric isolation door at an inlet of a flocking box are opened, and the horizontal driving mechanism drives a receiving mechanism through the rotary driving mechanism to drive the sampling swabs to be flocked to enter a flocking cavity. Flock discharging equipment outputs flock, the flock in the flocking cavity is adhered to the sampling heads of the sampling swabs to be flocked under the action of static electricity and mucilage glue, and the sampling swabs to be flocked rotate to further uniformly wind the flock on the sampling heads of the sampling swabs to be flocked.

Owner:叶曼钰

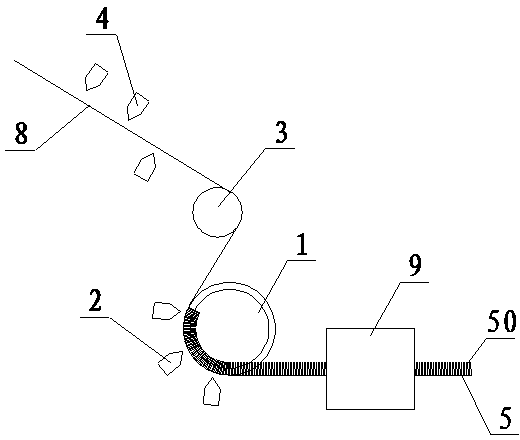

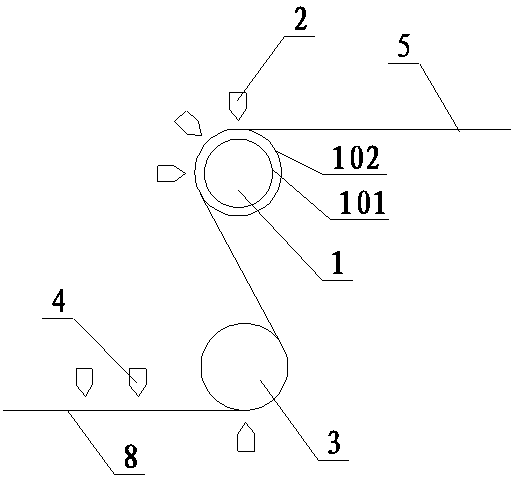

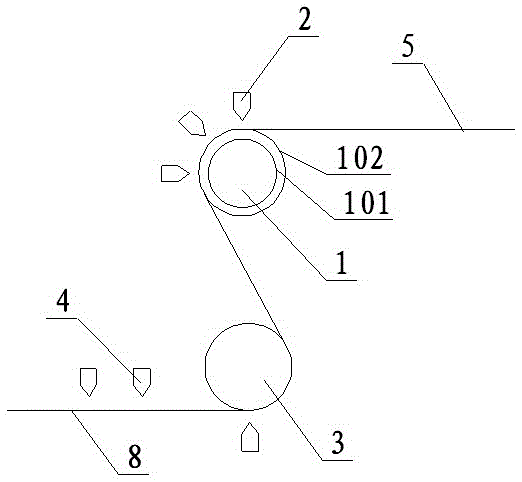

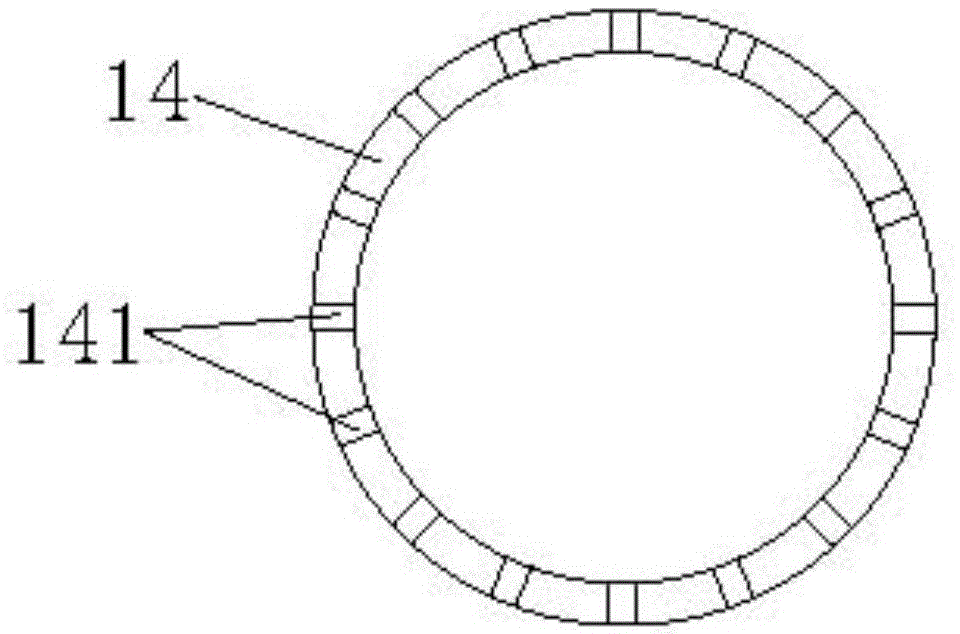

Spunlace flocking device and method

ActiveCN103437073AGuarantee the flocking qualityGuaranteed Tangling StrengthNeedling machinesEngineeringHigh pressure

The invention relates to a spunlace flocking device and a spunlace flocking method. The spunlace flocking device comprises a flocking wheel drum or trawl curtain and a high-pressure flocking spunlace head, wherein the high-pressure flocking spunlace head is arranged on the outer side of the locking wheel drum or trawl curtain; the locking wheel drum or trawl curtain is provided with a plurality of fine holes; after a fiber net is tangled through front spunlace, one ends of fine fibers extend into the fine holes through the flocking wheel drum or trawl curtain under the action of the spunlace of the high-pressure flocking spunlace head, and the ends of the fibers extending into the concave holes are taken out when non-woven fabric is separated from the flocking wheel drum or trawl curtain, so that flocks are formed on one face of the non-woven fabric to finish a flocking process for flocking the non-woven fabric. By using the spunlace flocking method, the flocking process of the non-woven fabric is simplified, the used device has the characteristics of simple structure, reduction in floor space and reduction in equipment and material cost, and the flocking effect of the non-woven fabric is also effectively guaranteed.

Owner:HANGZHOU NBOND NONWOVENS

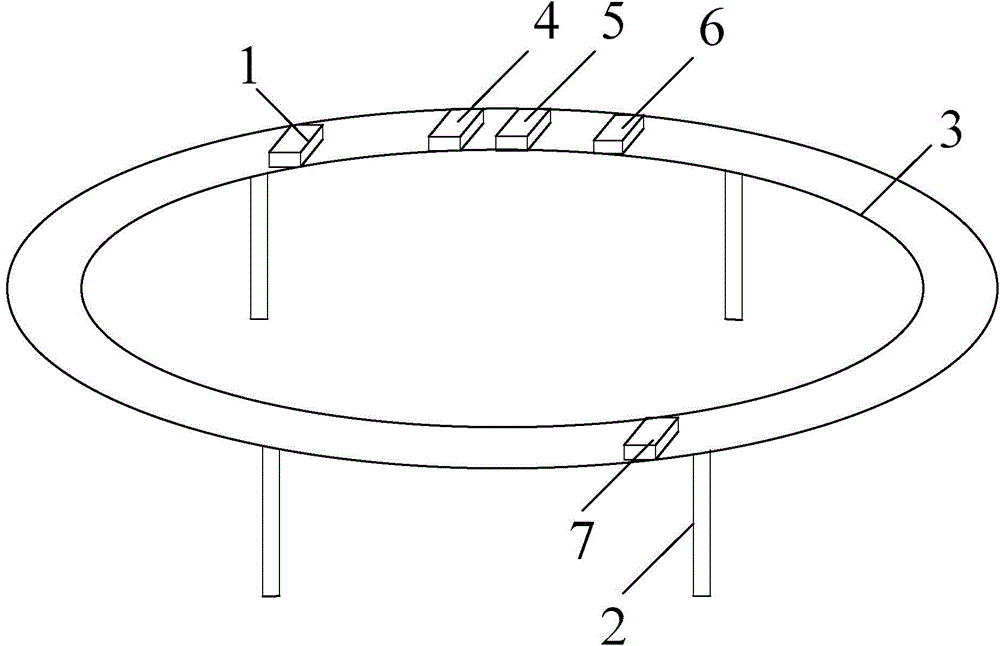

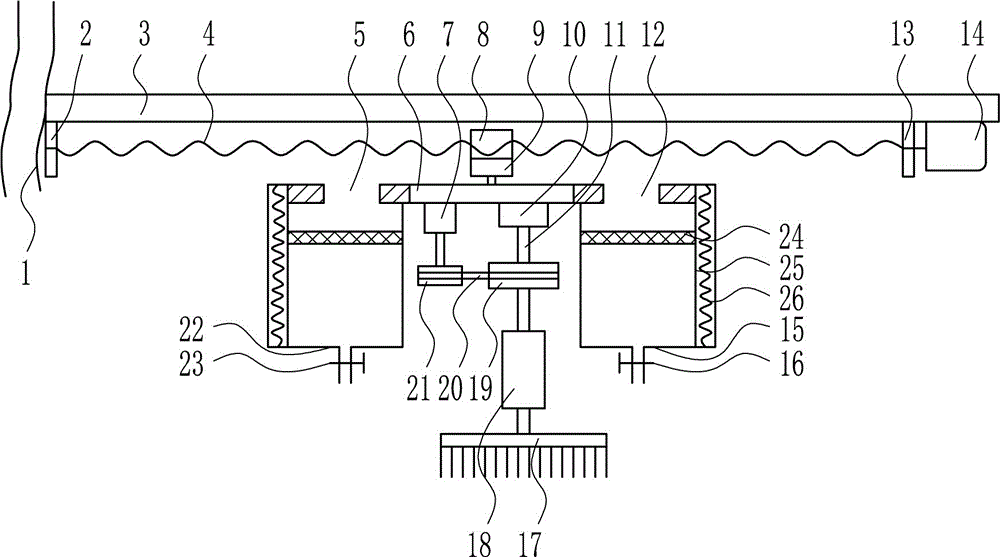

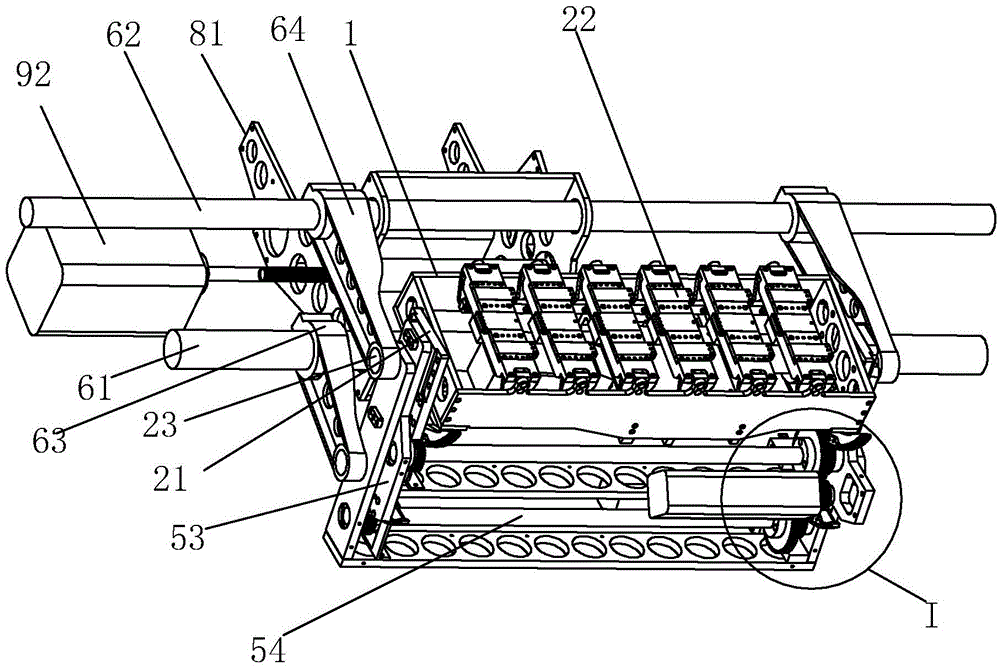

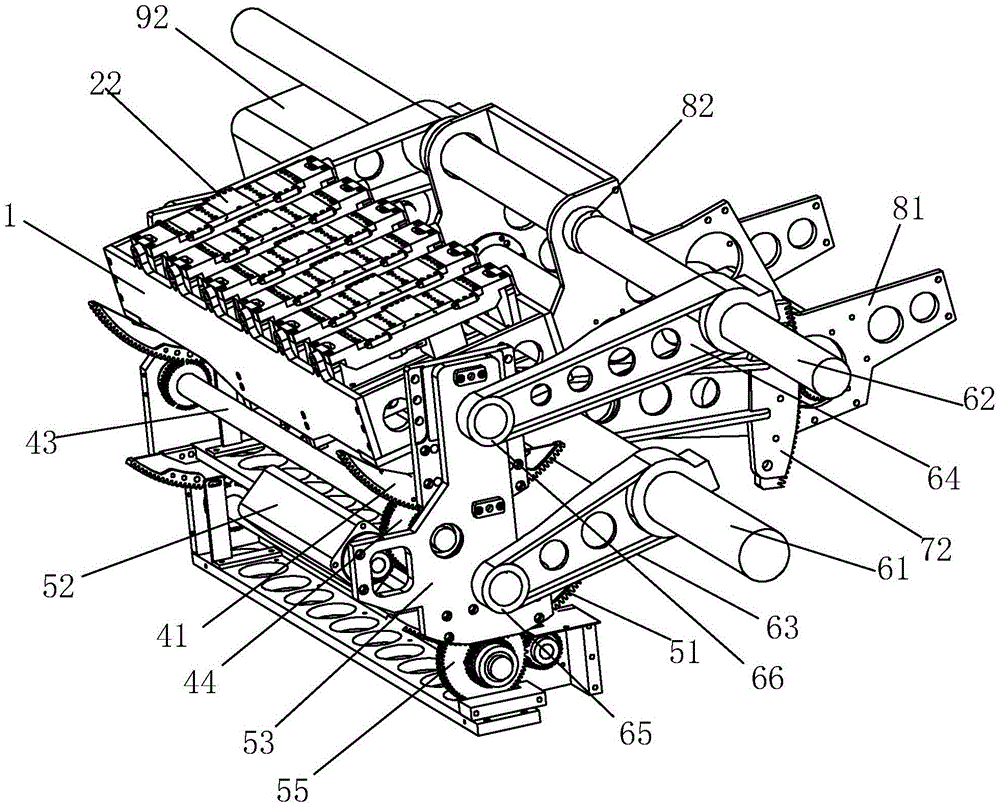

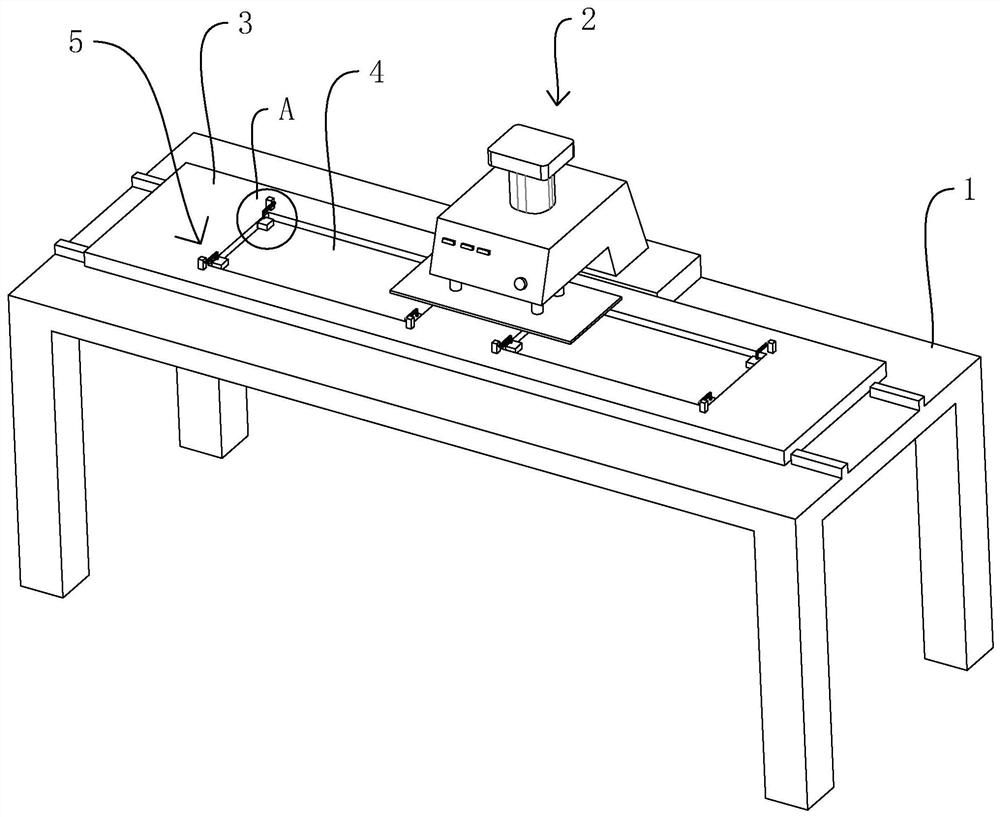

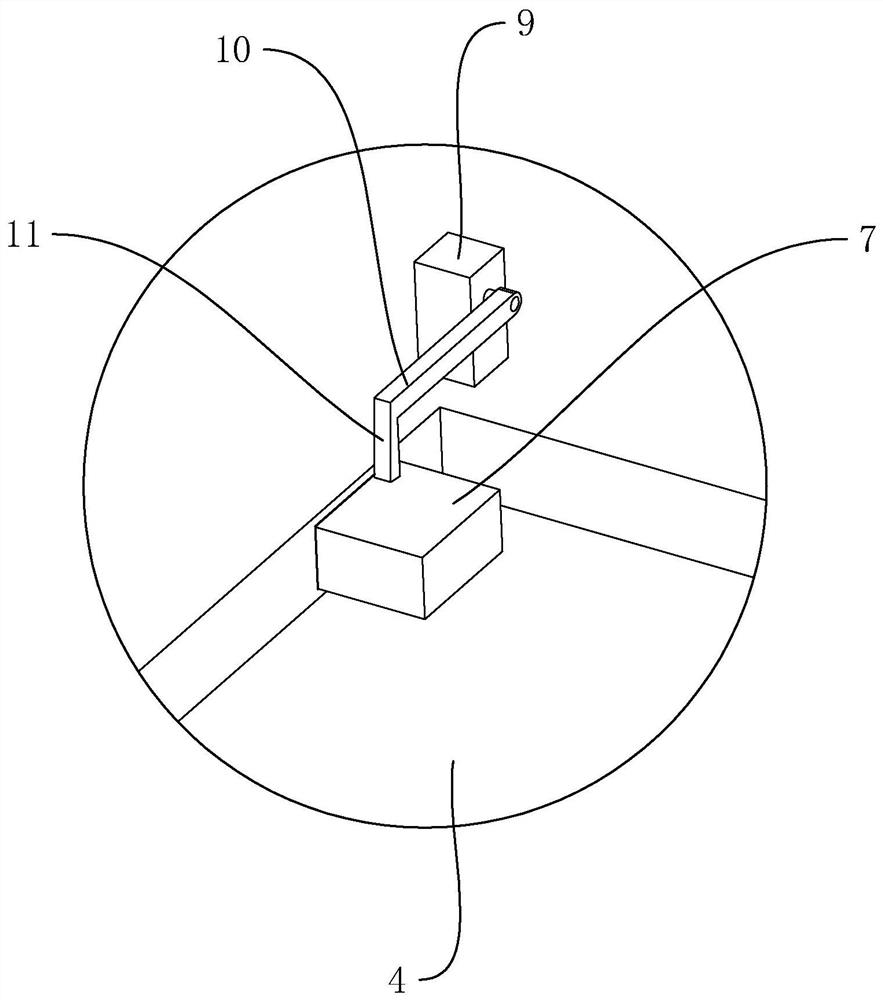

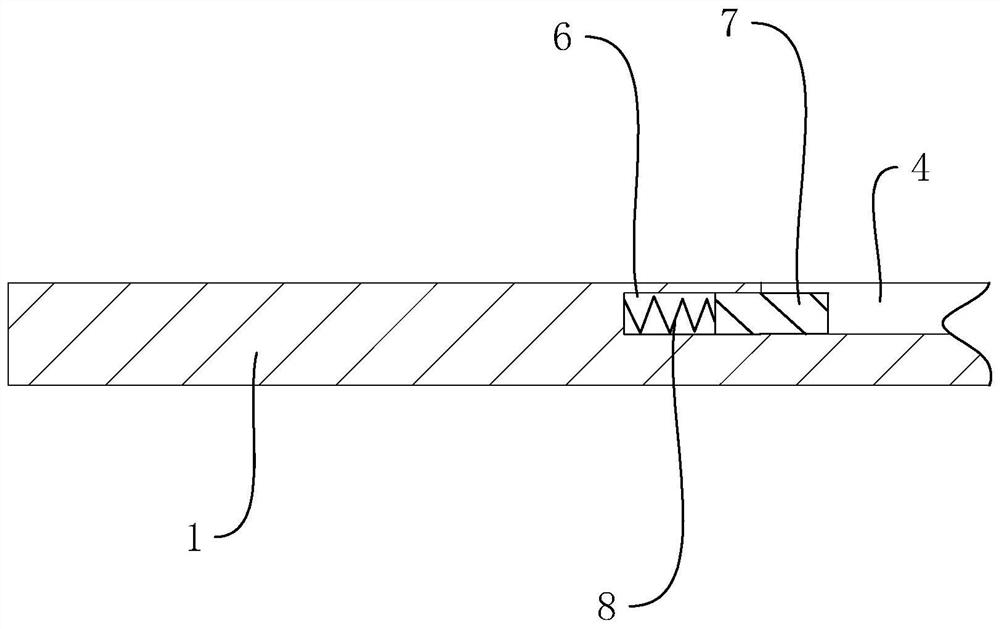

Worktable of hair planting machine

ActiveCN104523002AAdjustable positionAchieve regulationBrush bodiesEngineeringMechanical engineering

The invention discloses a worktable of a hair planting machine. According to the technical scheme, the worktable of the hair planting machine is characterized in that a first rotary shaft penetrates through a clamp platform, the clamp platform is rotationally connected with a frame body through the first rotary shaft and provided with a first driving device used for driving the clamp platform to rotate around the first rotary shaft, a supporting plate is provided with a second driving device used for driving the frame body to rotate around a fixed shaft, provided with a third driving device used for driving the supporting plate to move axially along the fixed shaft, and provided with a lifting device used for driving the supporting plate to ascend and descend, and omni-directional adjustment of the clamp platform is realized through the first driving device, the second driving device, the third driving device and the lifting device. In this way, even though a brush head is complex in shape, holes in the brush head are located in different positions, the brush head is fixed to the clamp platform, hair planting operation is realized by adjusting the position of the clamp platform, work efficiency is high, a good hair planting effect of the complex brush head is realized, and practicability is high.

Owner:台州市鸿跃机械有限公司

Flocked bra fabric production equipment and production technology

InactiveCN104664640ASimple processImprove work efficiencyPretreated surfacesBrassieresWear resistantEngineering

The invention discloses flocked bra fabric production equipment which comprises a control device and a rack, wherein a conveying device for conveying a bra fabric is arranged on the rack, a first spreading machine, a first drying machine, a second automatic spreading machine and an automatic flocking device are sequentially fixedly arranged on the rack above the conveying device; the flocked bra fabric production equipment further comprises a second drying machine which is separately arranged. The invention further discloses a flocked bra fabric production technology. The flocked bra fabric is produced by adopting the flocked bra fabric production equipment, the technology is simple, the flocking procedure is automatically completed, the needed worker labor intensity is small, the flocked bra fabric production equipment is environment-friendly and safe, and the working efficiency is improved by one to two times; the flocking consumption is greatly reduced, the production cost is lowered, the fluff on the flocked bra fabric is adhered firmly, wear-resistant, incapable of falling, and anti-aging; the flocked bra fabric is strong in the flocking three-dimensional feeling, bright in color, and soft in hand feeling, has non-toxic and tasteless, heat-insulating and moisture-proof effects, is incapable of falling, and is smooth and gapless, the quality of the product is high, and the flocking effect is improved.

Owner:TENGFEI TECH CO LTD

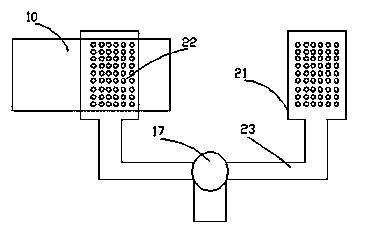

Multi-electric field electrostatic flocking method and equipment

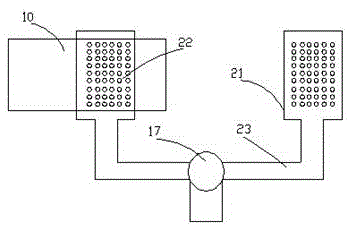

ActiveCN109225769AImprove qualityIncrease productivityLiquid surface applicatorsCoatingsHigh densityAfter treatment

The invention provides a multi-electric field electrostatic flocking method and equipment. The method comprises the following steps: coating a base material with an adhesive, and carrying out multi-electric field flocking, fixation, after-treatment and rolling, wherein the multi-electric field flocking step comprises the multiple flocking steps, the time interval between every two flocking steps is 0.5-5 seconds, the flocking is direct current electrostatic field flocking or alternating electrostatic field flocking, and two types of electrostatic fields can be repeatedly or alternately used. Compared with the prior art, the quality of a flocking product is improved, the high-density high-firmness flocking is realized, the production efficiency is improved, the working procedures are reduced, and the production cost is lowered.

Owner:潍坊青原新材料科技有限公司

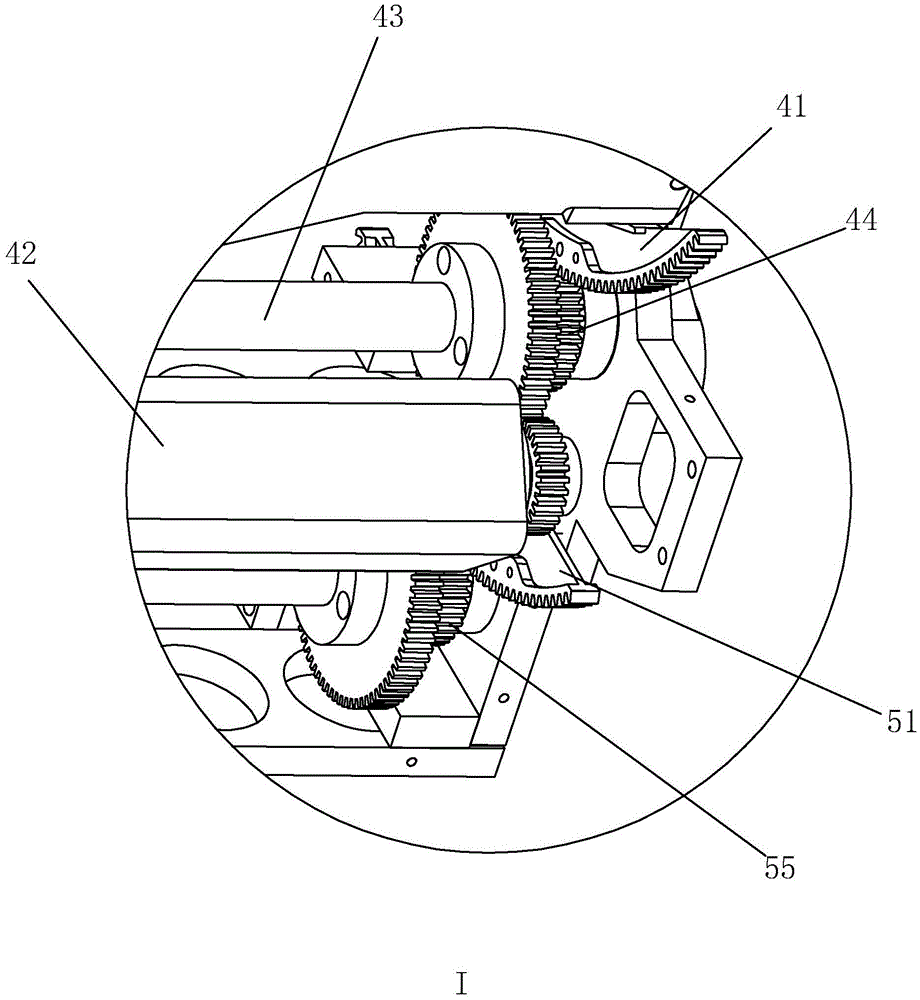

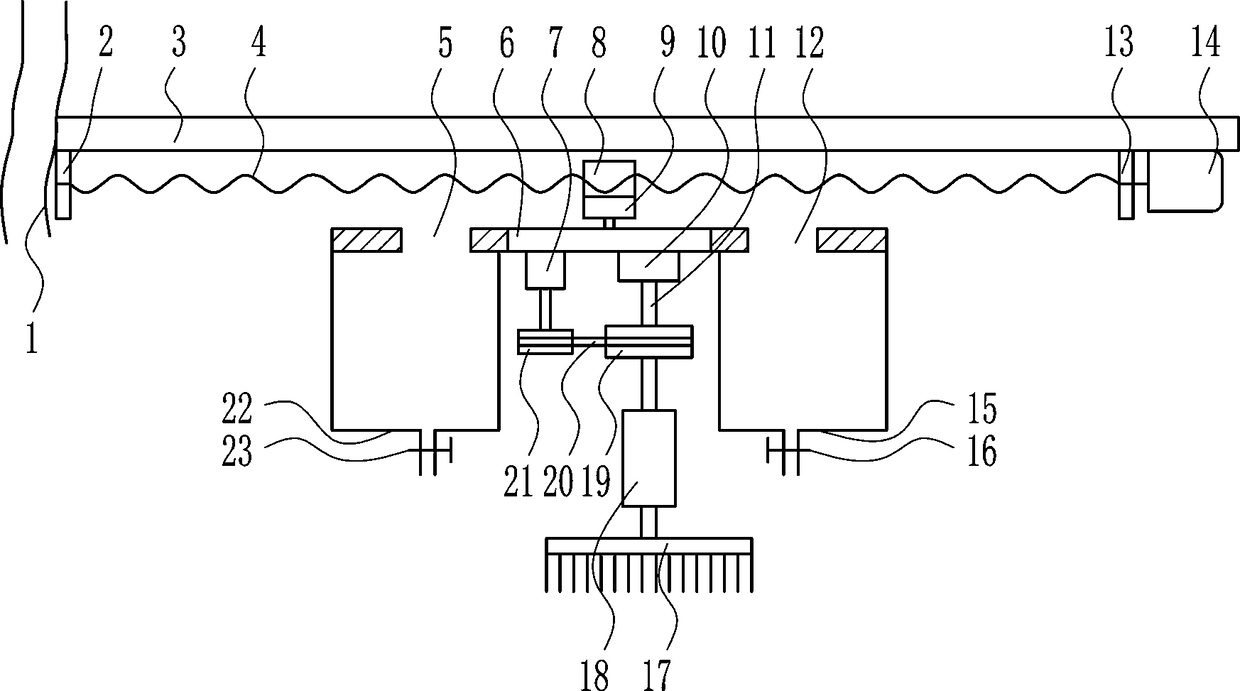

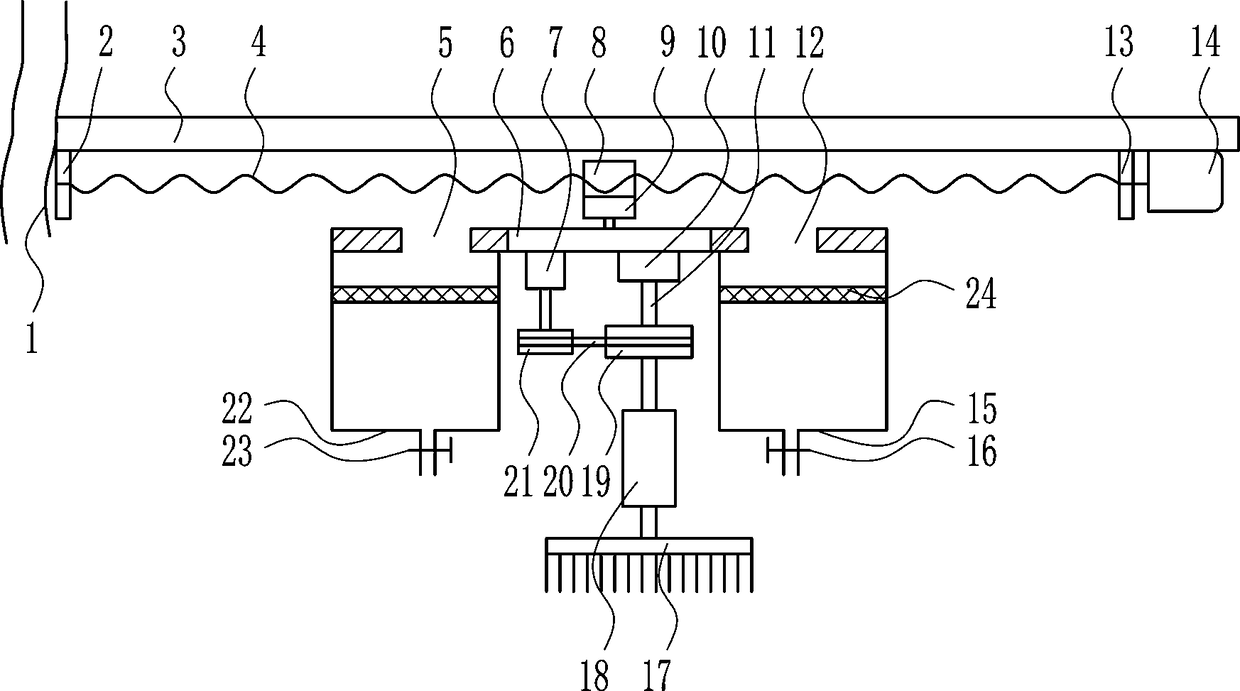

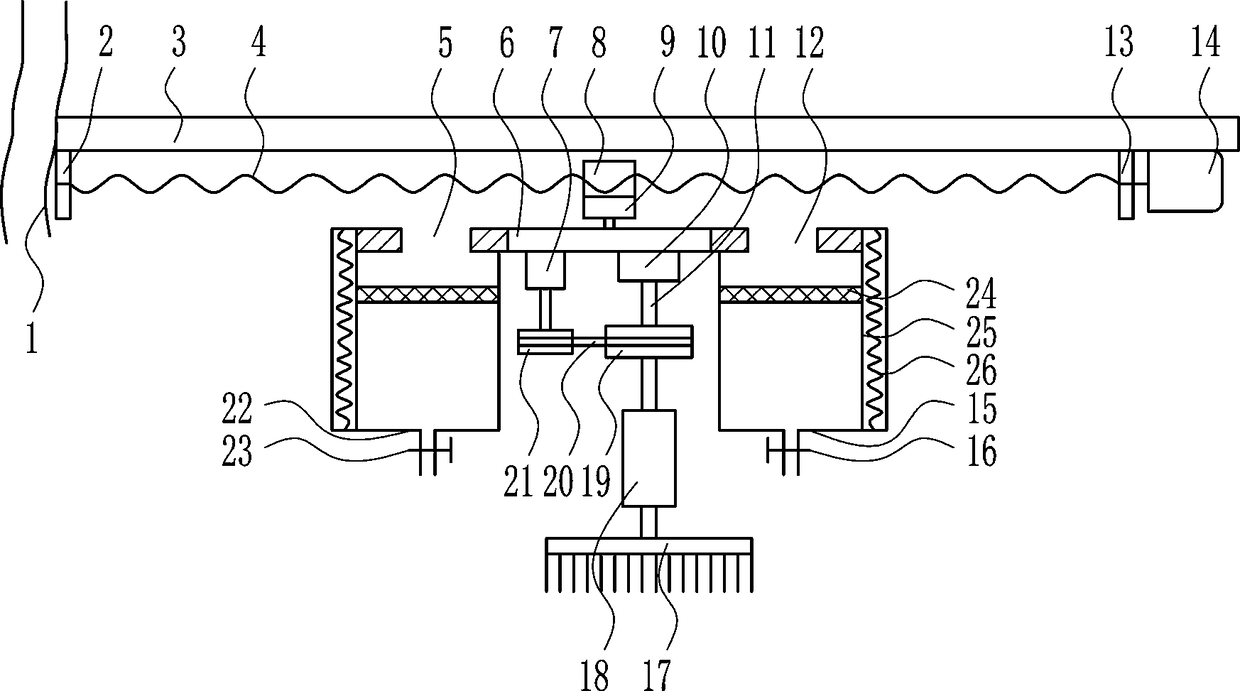

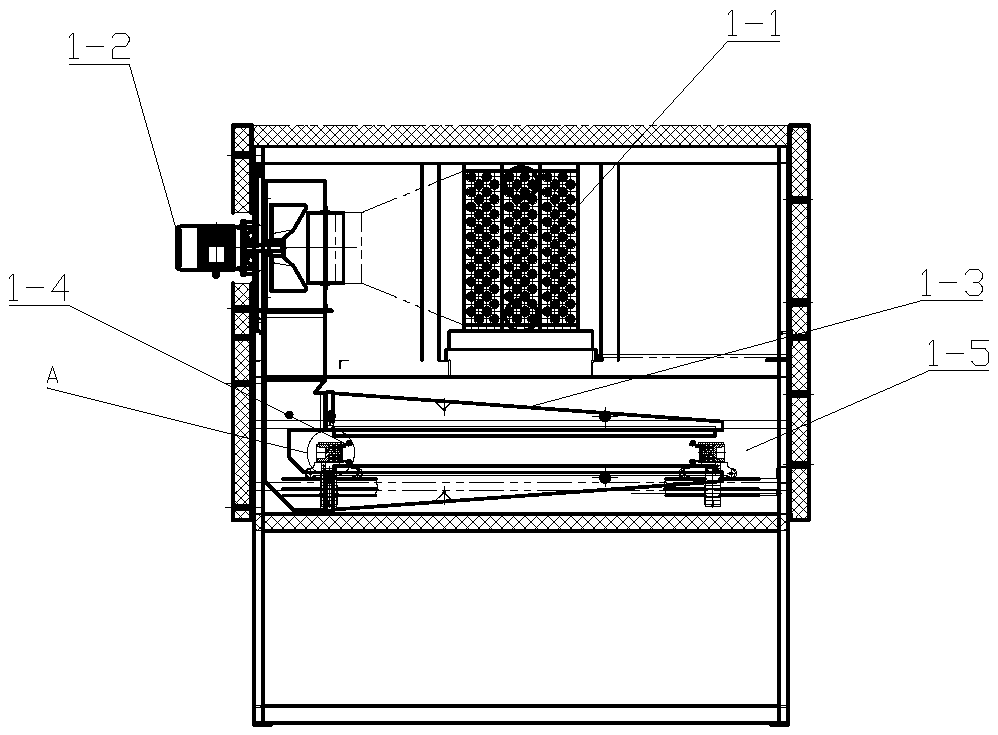

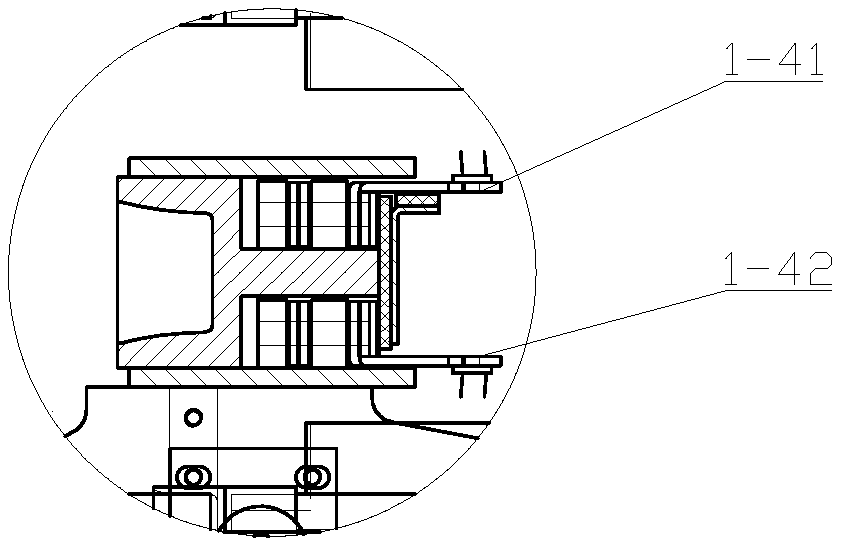

Efficient gluing device for flocking production processing

ActiveCN105908411AEven flockingImprove flocking efficiencyLiquid surface applicatorsTextile treatment machine arrangementsElectric machineryControl valves

The invention relates to a gluing device, in particular to an efficient gluing device for flocking production processing, and aims to solve the technical problem that an efficient gluing device for flocking production processing with uniform flocking, high flocking efficiency and good flocking effects is provided. To solve the technical problem, the invention provides the efficient gluing device for flocking production processing. The efficient gluing device comprises a hose, a left bearing seat, a top plate, a screw rod, a fixing plate, a motor I, a screw nut, a motor II, a bearing seat I, a rotating shaft, a right bearing seat, a motor III, a box body I, an electronic control valve I, a brush, an electronic push rod, a large belt pulley, a flat belt, a small belt pulley, a box body II and an electronic control valve II, wherein the hose is arranged on the left side of the top plate; the left bearing seat, the right bearing seat and the motor III are arranged from left to right in sequence at the bottom of the top plate; the screw rod is mounted between the left bearing seat and the right bearing seat. By adoption of the efficient gluing device, effects of uniform flocking, high flocking efficiency and good flocking effects are achieved.

Owner:河北博翼感光材料有限公司

Hair planting machine table

The invention discloses a worktable of a hair planting machine. According to the technical scheme, the worktable of the hair planting machine is characterized in that a first rotary shaft penetrates through a clamp platform, the clamp platform is rotationally connected with a frame body through the first rotary shaft and provided with a first driving device used for driving the clamp platform to rotate around the first rotary shaft, a supporting plate is provided with a second driving device used for driving the frame body to rotate around a fixed shaft, provided with a third driving device used for driving the supporting plate to move axially along the fixed shaft, and provided with a lifting device used for driving the supporting plate to ascend and descend, and omni-directional adjustment of the clamp platform is realized through the first driving device, the second driving device, the third driving device and the lifting device. In this way, even though a brush head is complex in shape, holes in the brush head are located in different positions, the brush head is fixed to the clamp platform, hair planting operation is realized by adjusting the position of the clamp platform, work efficiency is high, a good hair planting effect of the complex brush head is realized, and practicability is high.

Owner:台州市鸿跃机械有限公司

Electrostatic flocking method for automobile interior parts

ActiveCN102527599BImprove performanceGood wear fastnessLiquid surface applicatorsLayered productsAdhesion forceAdhesive

The invention discloses an electrostatic flocking method for automobile interior parts, which includes the following steps of (1) surface polishing; (2) adhesive coating; (3) electrostatic flocking; (4) curing; and (5) cleaning. The electrostatic flocking method for the automobile interior parts is simple in process, low in cost, high in production efficiency and finished product yield, wide in applicable range and suitable for various materials. The flocked products of the automobile interior parts manufactured by the method have standing flocks and have the advantages of excellent wear resistance, adhesion force, desiccation resistance, wet-cleaning resistance, cold resistance, clacking resistance, fine touch and the like. In addition, since the selected adhesive is made of environment-friendly raw materials, no pollution can be caused during use of the method.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

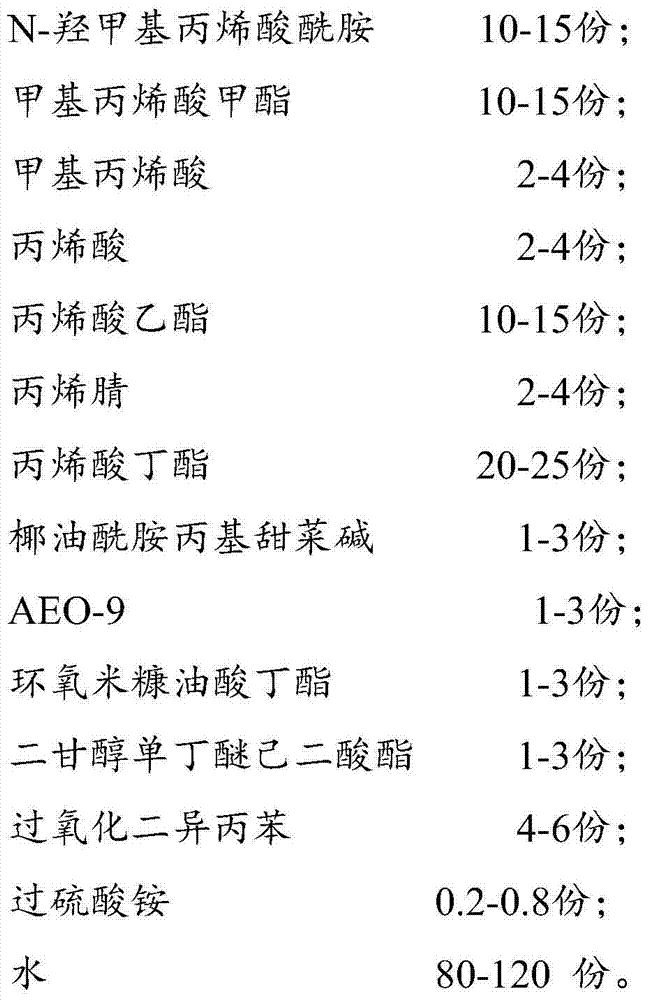

Electrostatic flocking adhesive and preparation method thereof

The invention relates to the technical field of electrostatic flocking adhesives and discloses an electrostatic flocking adhesive and a preparation method thereof. The electrostatic flocking adhesivecomprises butyl acrylate, acrylic nitrile, acrylic acid, N-hydroxymethyl acrylamide, lauryl sodium sulfate, O pi-7, a potassium peroxodisulfate reagent and deionized water. The electrostatic flockingadhesive and the preparation method thereof have the advantages of being stable in quality, low in cost, good in flocking effect, simple and efficient to prepare, and the like, the wearing solidness of a flocking product can be improved, the hand feeling of the flocking product can be improved, and in addition, with the combination of the lauryl sodium sulfate and the O pi-7, the stability of theelectrostatic flocking adhesive can be improved, and the product quality can be improved.

Owner:嘉善欣达胶业有限公司

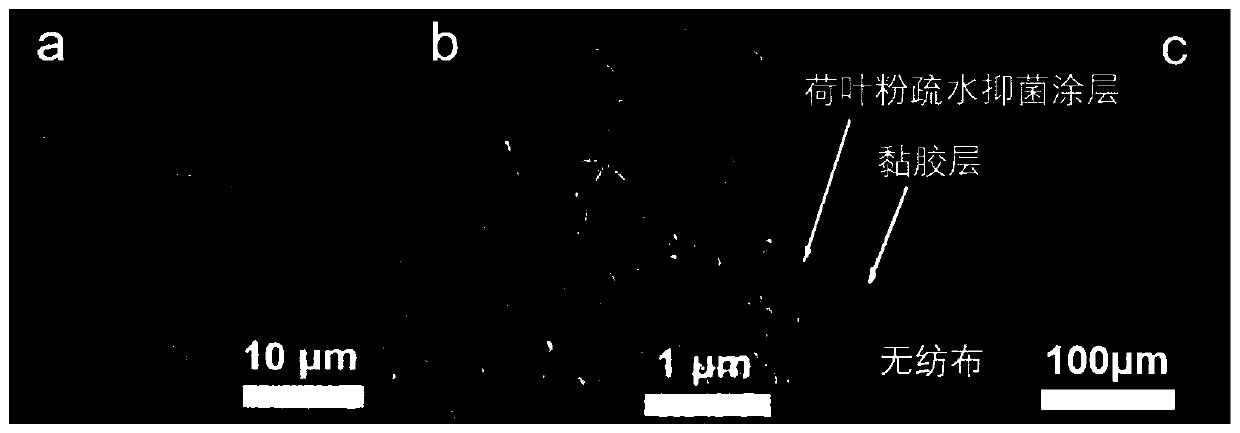

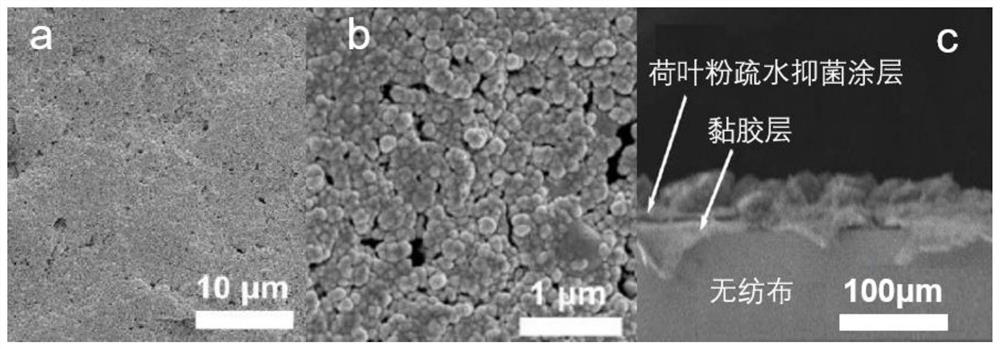

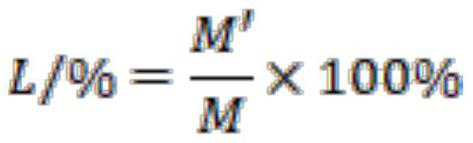

Hydrophobic and bacteriostatic multifunctional coating fabric and preparation method thereof

ActiveCN110952342AReduce contact areaNot wetLiquid spraying plantsCoatingsNonwoven fabricOrganic chemistry

The invention discloses a hydrophobic and bacteriostatic multifunctional coating fabric and a preparation method thereof. Natural lotus leaf powder is fixed on the surface of a non-woven fabric through an electrostatic flocking method to prepare the coating fabric with good hydrophobic and bacteriostatic functions. By the electrostatic flocking method, the lotus leaf powder can uniformly coat thesurface of the non-woven fabric while maintaining the special hydrophobic and bacteriostatic activity; and the advantages of high attachment firmness and flocking density controllability are realized.Meanwhile, the natural lotus leaf powder is used as a mildew-proof bacteriostatic agent to prepare the multifunctional coating fabric; the raw material sources of lotus leaves are wide; the cost is low, so that the production cost of the multifunctional coating fabric is favorably reduced; and the utilization rate of the lotus leaves is improved. The preparation method is simple and fast; the flocking effect is good; the existing equipment can be used for preparation; and the industrialization is easy.

Owner:WUHAN TEXTILE UNIV

Flocking process of automobile interior trim back storage box

The invention discloses a flocking process of an automobile interior trim back storage box, and relates to an electrostatic flocking process for automobile interior trim parts. The flocking process mainly aims to solve the problems of glue cracking and burning in an existing flocking process. The flocking process comprises the following steps that dyeing and electrical treatment of fluff are carried out, a plastic part is ground by using a brush to enable the surface of the plastic part to be rough, plasma treatment on the plastic part is carried out, the surface of the plastic part is cleanedby using a degreasing agent and a cleaning agent, and the surface of the plastic part is dried after watering; the surface of the plastic part is degreased with robot flame; an adhesive is sprayed onthe surface of the plastic part, and the plastic part is dried in the baking line; the plastic part is placed on a working table of a flocking machine, the fluff is added into the flocking machine, the flocking machine is started, and the fluff is sprayed out by a spray head under the action of a high-pressure electrostatic field and then vertically adhered to the surface of the plastic part; theplastic part is placed in a drying room for drying after flocking is finished; and the floating fluff is removed by adopting an electrostatic dust removal air gun, and flushing is carried out. The flocking process has the advantages that the phenomena of adhesive cracking and burning are avoided, and the flocking effect is good.

Owner:JINXING AUTOMOTIVE INTERIOR DECORATION

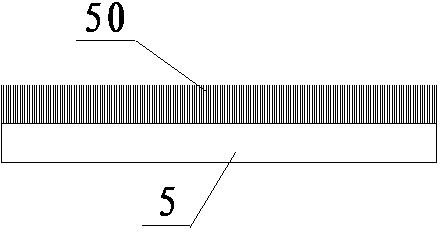

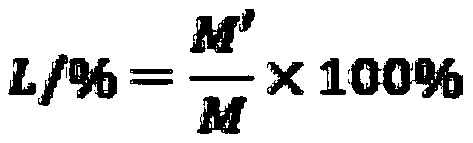

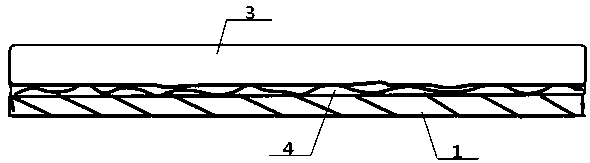

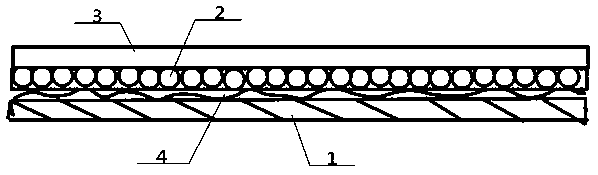

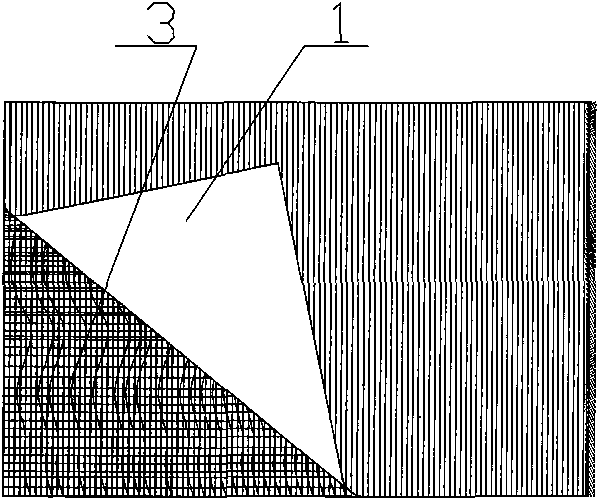

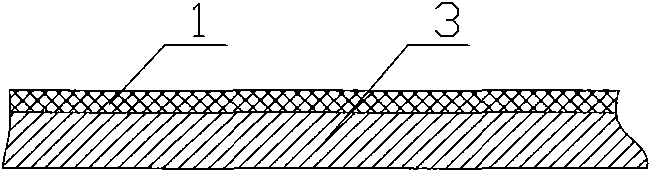

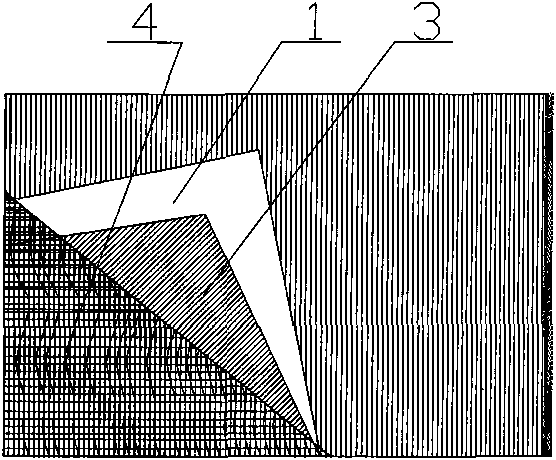

Water swelling type water-blocking belt for optical cables and cables and preparation method thereof

PendingCN109308955AProtective coreDoes not block immersionSynthetic resin layered productsLaminationWater blockMetal

The invention discloses a water swelling type water-blocking belt. The water-blocking belt includes a matrix layer, a water-absorbing layer and a protective layer; the inner wall of the matrix layer is in contact with the external of an optical cable or a cable; the bottom of the water-absorbing layer is connected to the outer wall of the matrix layer; the protective layer externally wraps the part, other than the junction part of the water-absorbing layer and the matrix layer, on the water-absorbing layer; the bottom of the protective layer covers the junction part of the water-absorbing layer and the matrix layer; the water-absorbing layer contains a superabsorbent expansion material; the protective layer is a thin film which can be dissolved after absorbing water; a bonding layer can bearranged between the matrix layer and the water-absorbing layer; and the matrix layer is preferred to be metal. The water-blocking belt is strong in water absorbing and blocking performance, less inlayer, simple and light in structure, high in water swelling multiple, high in water-absorbing efficiency and good in water blocking performance; influences on the using of the optical cables or the cables cannot be caused; and the water-blocking belt has advantages of shielding signals and preventing rats from biting.

Owner:WUHAN TEXTILE UNIV

A kind of spunlace flocking device and method

ActiveCN103437073BGuarantee the flocking qualityGuaranteed Tangling StrengthNeedling machinesEngineeringNonwoven fabric

The invention relates to a spunlace flocking device and a spunlace flocking method. The spunlace flocking device comprises a flocking wheel drum or trawl curtain and a high-pressure flocking spunlace head, wherein the high-pressure flocking spunlace head is arranged on the outer side of the locking wheel drum or trawl curtain; the locking wheel drum or trawl curtain is provided with a plurality of fine holes; after a fiber net is tangled through front spunlace, one ends of fine fibers extend into the fine holes through the flocking wheel drum or trawl curtain under the action of the spunlace of the high-pressure flocking spunlace head, and the ends of the fibers extending into the concave holes are taken out when non-woven fabric is separated from the flocking wheel drum or trawl curtain, so that flocks are formed on one face of the non-woven fabric to finish a flocking process for flocking the non-woven fabric. By using the spunlace flocking method, the flocking process of the non-woven fabric is simplified, the used device has the characteristics of simple structure, reduction in floor space and reduction in equipment and material cost, and the flocking effect of the non-woven fabric is also effectively guaranteed.

Owner:HANGZHOU NBOND NONWOVENS

A high-efficiency gluing device for flocking production and processing

ActiveCN105908411BEven flockingImprove flocking efficiencyLiquid surface applicatorsTextile treatment machine arrangementsEngineeringControl valves

Owner:河北博翼感光材料有限公司

An electrostatic flocking process and its device

InactiveCN103846205BReduce labor intensityImprove efficiencyPretreated surfacesElectrostatic spraying apparatusEngineering

The invention discloses an electrostatic flocking process and an electrostatic flocking device used in the electrostatic flocking process, which includes a pre-coating device, a coloring device and a flocking device, and a The four-wheel rectifying structure has a lint cleaning structure at the rear; the structure of the invention is simple and exquisite, and the flocking effect is good, which can realize color flocking and automatic flocking at the same time. Aging, friction resistance, non-shedding, with sound-absorbing function and dust-absorbing and air-purifying function.

Owner:孙有峰

Preparation method of flocking glue for spinning

InactiveCN112724892AEasy to prepareEasy to operatePolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolymer scienceMeth-

The invention discloses a preparation method of a flocking adhesive for spinning, which comprises the following steps: S1, in a reaction kettle, adding hyperbranched waterborne polyurethane acrylate, O-(ethylene oxybutyl)-N-(triethoxy silylpropyl)urea, acrylic acid-L-menthyl acrylate, polynorbornene-2, 3-dicarboxylic acid polytetrahydrofuran glycol ester, acrylic acid-2, 3-epoxypropyl ester modified 1-amino benzotriazole, crylic acid hexahydro-4, 7-methylene-1H- indenyl acrylate, an emulsifier and ethanol into part of water, and stirring until the components are uniformly mixed; and S2, adding the rest water into the mixture prepared in the step S1, slowly adding the mixture into the reaction kettle under the protection of nitrogen or inert gas at the temperature of 60-70 DEG C, slowly adding an initiator, and carrying out a constant-temperature reaction for 4-6 hours to obtain the flocking adhesive for spinning. The prepared flocking adhesive for spinning is good in wear resistance, moisture resistance, water resistance, solvent resistance and heat resistance, good in flocking effect, excellent in performance stability and high in peel strength.

Owner:朱建余

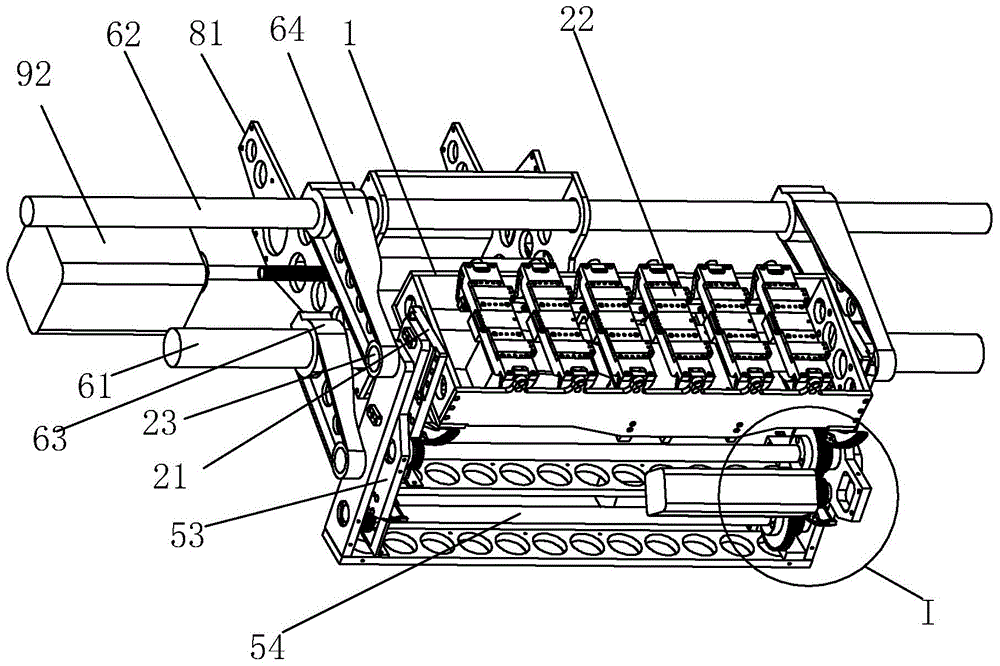

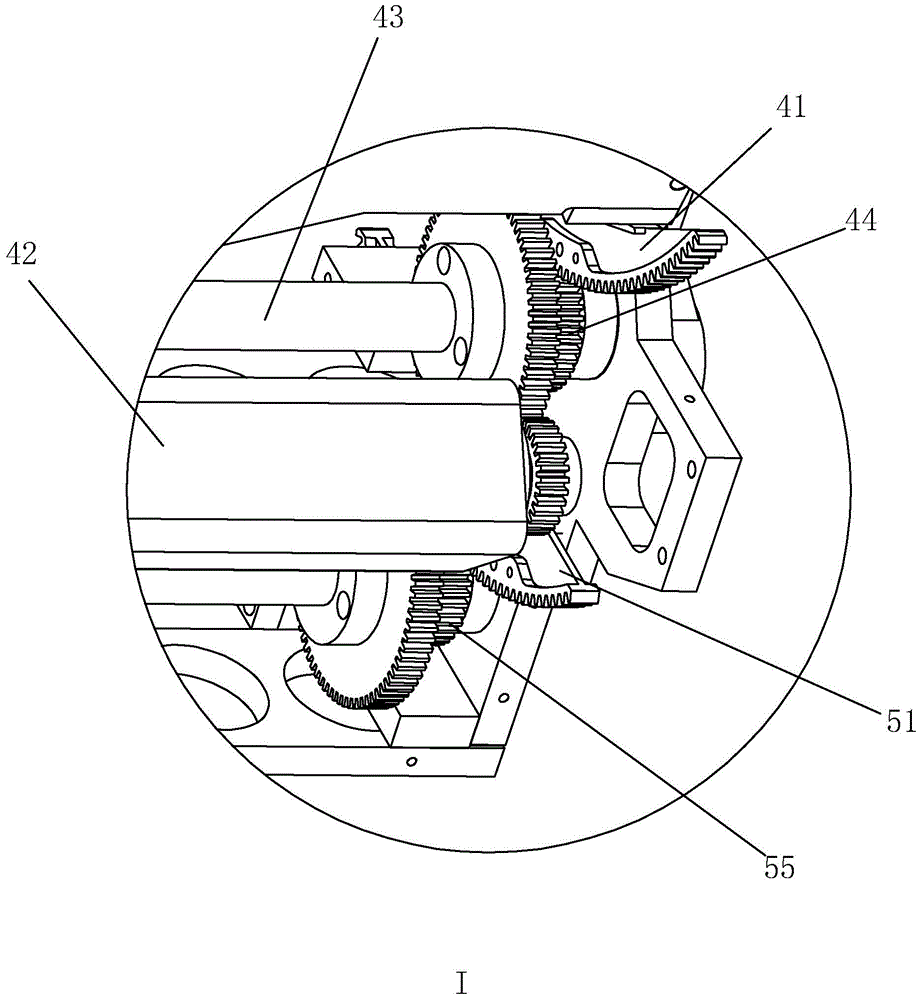

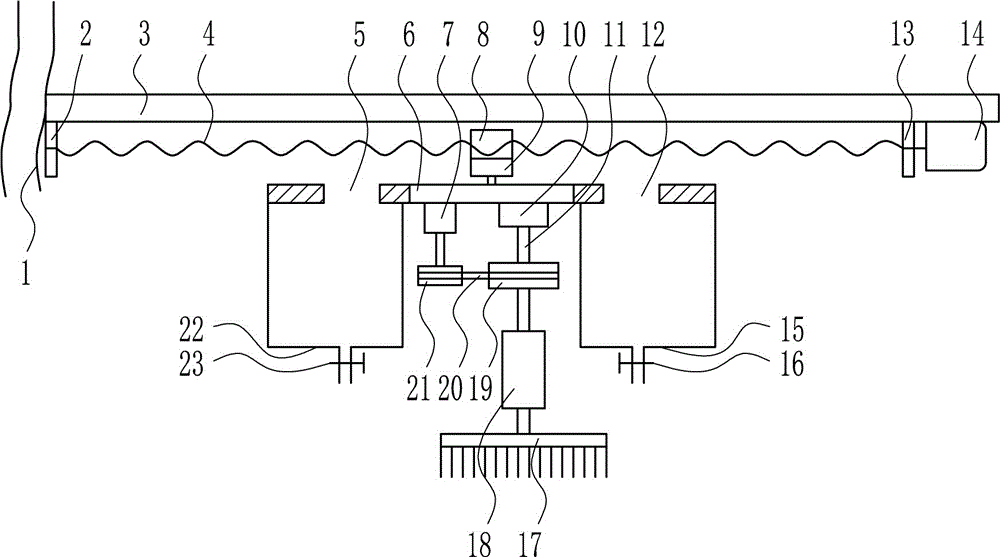

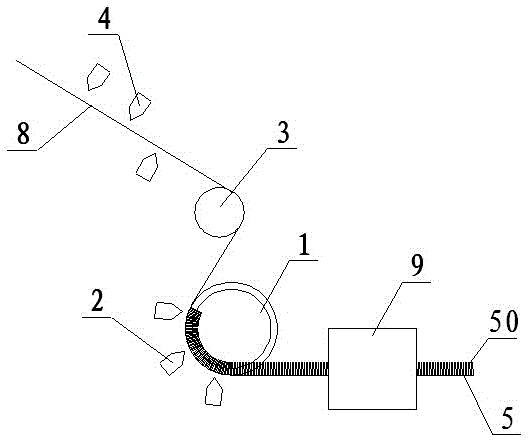

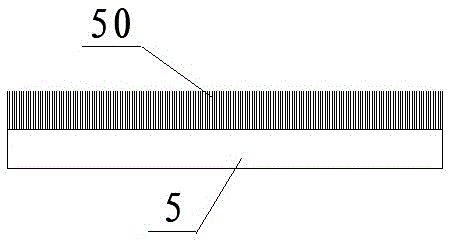

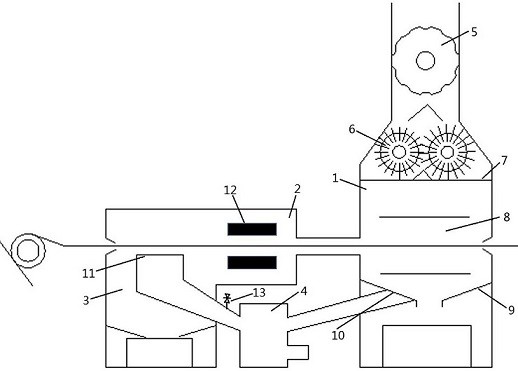

Paper gravure continuous positioning and flocking method and apparatus thereof

ActiveCN102518000BGood flocking effectGood flocking fastnessSurface covering paperLiquid surface applicatorsPulp and paper industryPrinting press

Owner:SHANTOU FANGDA INNOVATIVE TECH

A processing technology of flocking tag and automatic heat press machine used in the technology

ActiveCN110170428BEasy to processReduce manufacturing costPretreated surfacesCoatingsPaperboardProcess engineering

The invention relates to a processing technology of a flocking tag and an automatic heat press machine used for the technology, and relates to the technical field of tag production, and the technology specifically includes: cardboard pulping, flocking board compounding, feeding flocking, and returning material to cool , Tear material cutting. The beneficial effects of the present invention are as follows: firstly, the production steps of hangtags are reduced, the process of printing is omitted, the production process of hangtags is simplified, and the production cost is greatly saved; Sufficient cooling and solidification makes the cardboard and the fluff on the flocking board fully bonded; third, the processed hang tag material is environmentally friendly and easy to degrade, which improves its environmental protection; fourth, the fluff on the surface of the hang tag makes the hang tag more three-dimensional and aesthetic .

Owner:浙江美宝物联网科技股份有限公司

A high-efficiency flocking device for removing wrinkles of interlining

InactiveCN104210215BEliminate static electricityImprove qualityLamination ancillary operationsLaminationInterliningWrinkle skin

Owner:WENZHOU HANJIESI LINING CLOTH

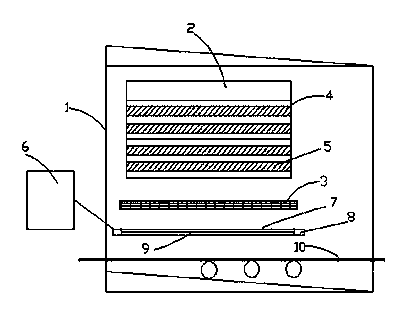

Oven structure for flocking machine

InactiveCN110813672AFreeze fastGood flocking effectPretreated surfacesCoatingsAdhesive glueEngineering

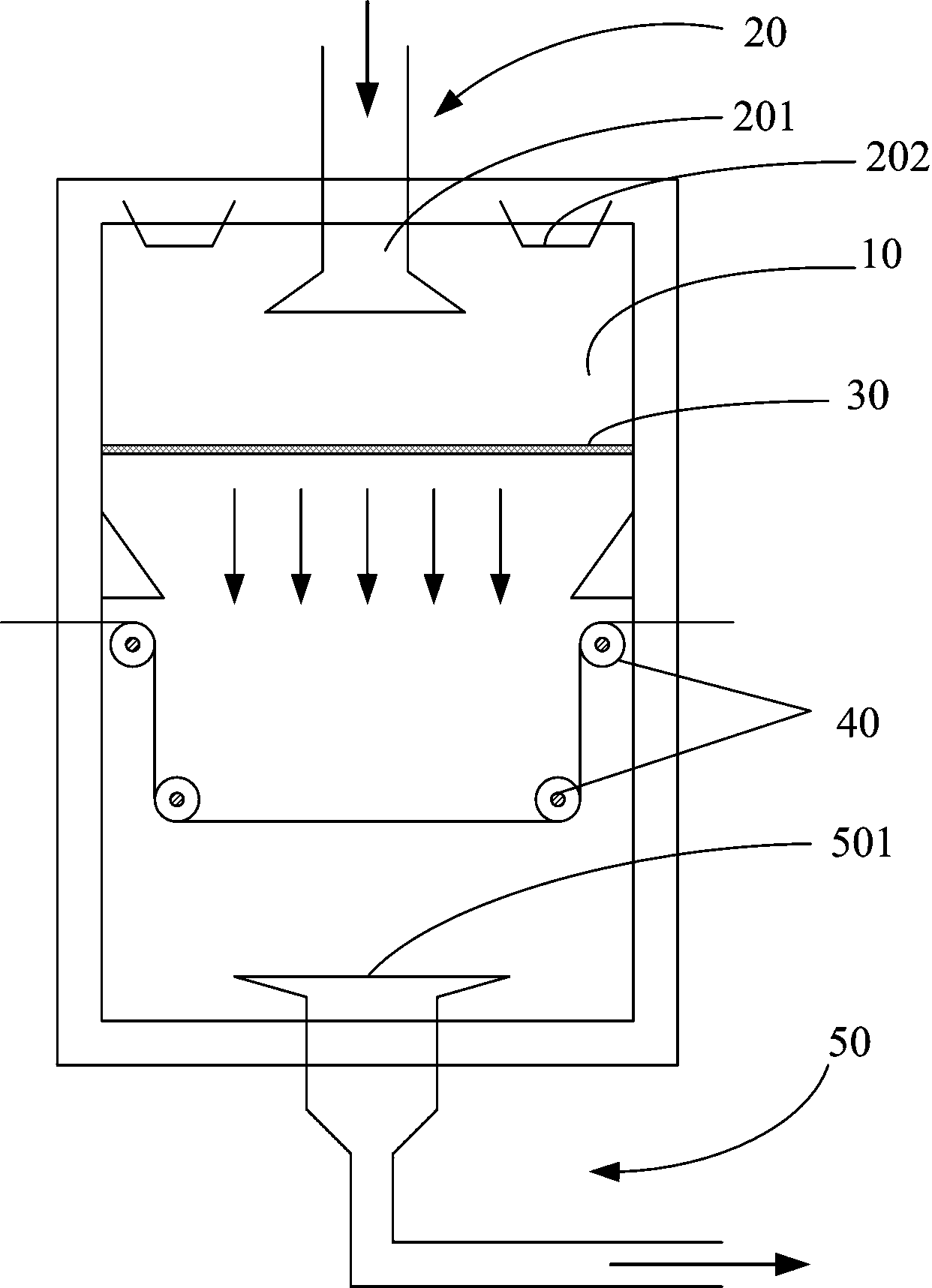

The invention provides an oven structure for a flocking machine. The oven structure does not transfer the heat of an oven to gluing equipment, so that too fast solidification of glue is avoided. The oven structure comprises a heating device, a fan and a heating chamber, wherein an air guide plate is arranged in the heating chamber, and a conveying chain loaded with a flocking base material is arranged penetrating through the heating chamber; and the oven structure further comprises an isolation chamber separated from the heating chamber, and the conveying chain returned from the end point of the flocking machine and not loaded with the flocking base material is arranged penetrating through the isolation chamber.

Owner:WUXI QUANSHUN MACHINERY MFG

A yarn flocking mechanism integrating flocking drying and removing excess velvet

ActiveCN110947592BEvenly dispersedPrevent solidificationPretreated surfacesCoatingsYarnAdhesive glue

Owner:浙江久大纺织科技有限公司

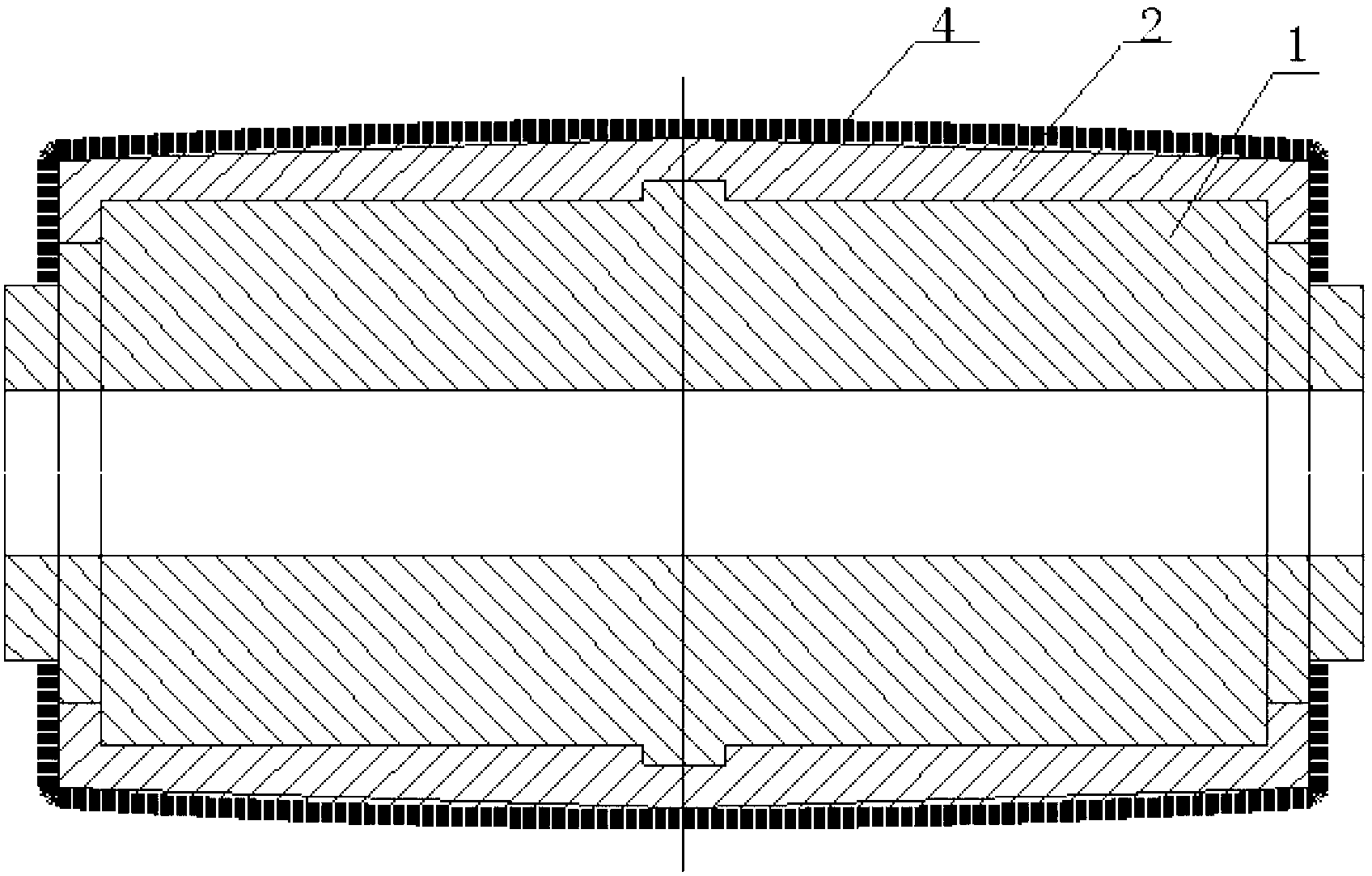

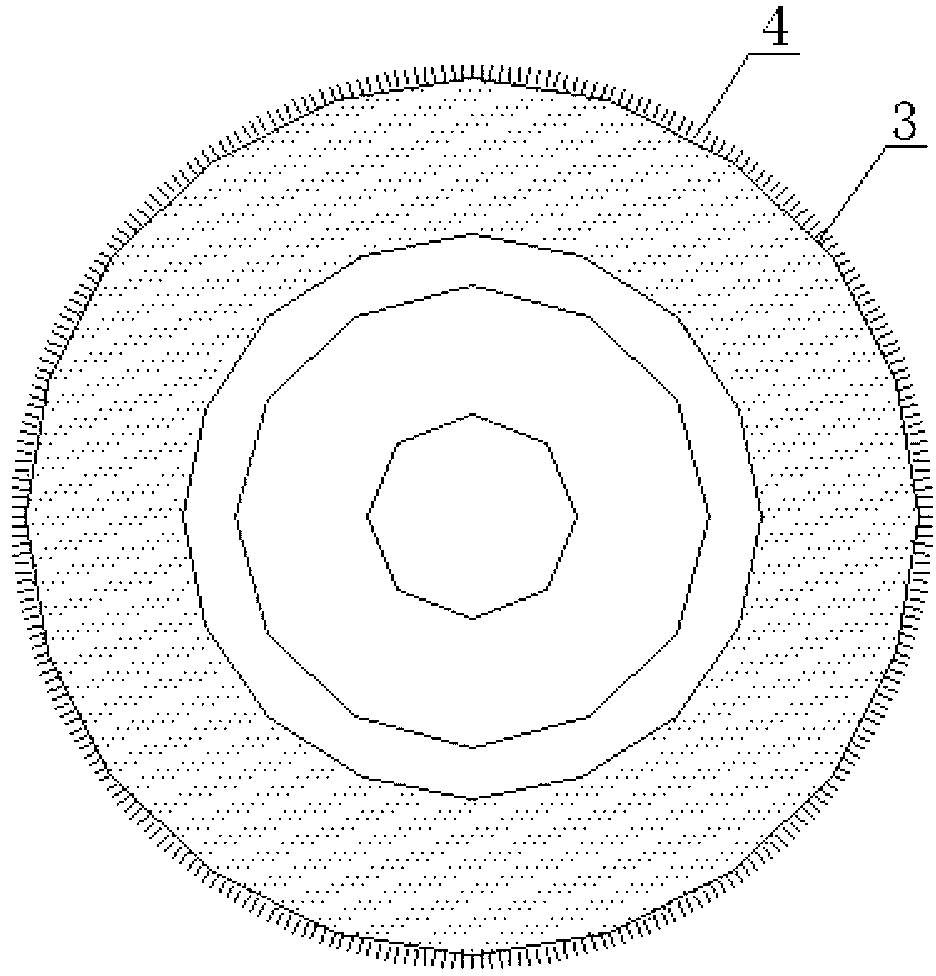

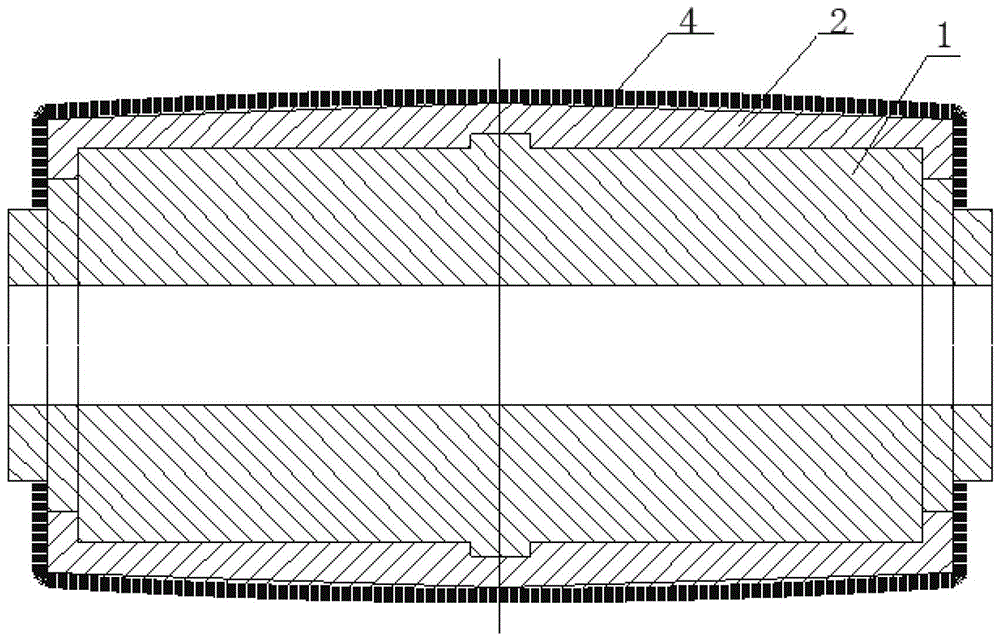

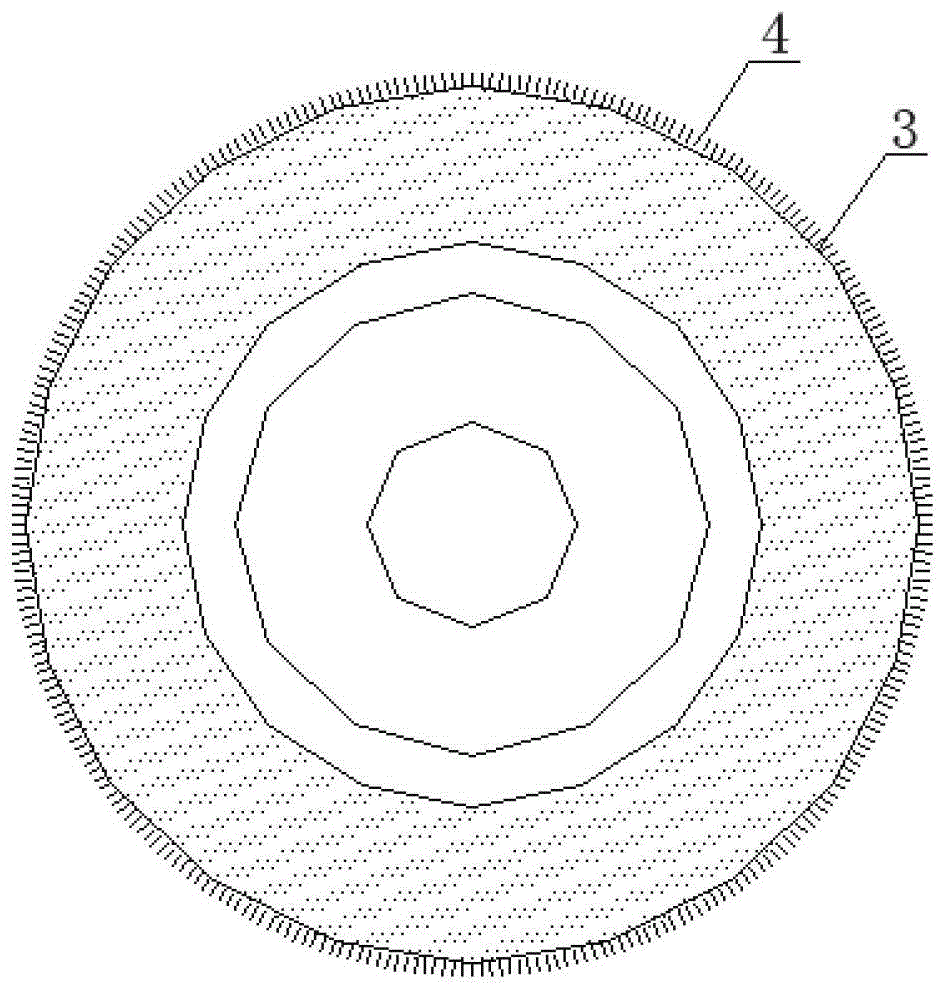

Flocking roller and flocking method thereof

InactiveCN103264009AGood elasticityGood wear resistanceLiquid surface applicatorsCoatingsSurface finishingEngineering

The invention discloses a flocking roller and a flocking method thereof. The flocking roller comprises a roller polyoxymethylene (POM) core, wherein an adhesive coating layer wraps the roller POM core; a flocking supporting layer is arranged on the surface of the adhesive coating layer; and flock layers which are vertically arranged are coated on the surface of the flocking supporting layer. The invention also discloses the flocking method of the flocking roller. The method comprises the following steps of: firstly, performing surface treatment on the adhesive coating layer of the roller; and secondly, performing surface flocking under the conditions of certain temperature, certain humidity and high-voltage static electricity. According to the flocking roller and the flocking method, after flocking, an adhesive film is soft, elastic, good in stereoscopic impression, shock-absorbing, noise-reducing, and friction-resisting; and frocks are unlikely to drop.

Owner:WUXI MEDICAL INSTR

A kind of hydrophobic and antibacterial multifunctional coated cloth and preparation method thereof

ActiveCN110952342BGood hydrophobic antibacterial functionUniform coatingLiquid spraying plantsCoatingsNonwoven fabricOrganic chemistry

Owner:WUHAN TEXTILE UNIV

Plasma flocking method for automobile interior parts

ActiveCN102527600BEasy to handleDoes not affect appearanceNon-macromolecular adhesive additivesPretreated surfacesAdhesion forceAdhesive

The invention discloses a plasma flocking method for automobile interior parts, which includes the following steps of (1) surface polishing; (2) adhesive coating; (3) electrostatic flocking; (4) curing; and (5) cleaning. The plasma flocking method for the automobile interior parts is simple in process, low in cost, high in production efficiency and finished product yield, wide in applicable range and suitable for various materials, realizes flocking on surfaces of the interior parts in different shapes and further can treat complicated structures effectively by means of plasma surface treatment. The flocked products of the automobile interior parts manufactured by the method have standing flocks and have the advantages of excellent wear resistance, adhesion force, desiccation resistance, wet-cleaning resistance, cold resistance, clacking resistance, fine touch and the like. In addition, since the selected adhesive is made of environment-friendly raw materials, no pollution can be caused during use of the method.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

A multi-electric field electrostatic flocking method and device

ActiveCN109225769BImprove qualityIncrease productivityLiquid surface applicatorsCoatingsHigh densityAdhesive

Owner:潍坊青原新材料科技有限公司

Swab flocking device and swab fluff blowing and flocking process

PendingCN114192361AQuality assuranceReduce demandSurgical needlesVaccination/ovulation diagnosticsElectric machineControl theory

The invention discloses a swab flocking device and a swab fluff blowing and flocking process, a conveying drag chain transversely penetrates through a flocking box, a plurality of swab hangers are arranged on the conveying drag chain at intervals, and the conveying drag chain is connected with a first motor; a plurality of fans are arranged in the flocking box and located on the outer side of the conveying drag chain; during flocking, the swab rod is hung on the swab hanging frame and is conveyed forwards by the conveying drag chain, and the fluff is blown to the end of the swab rod by the plurality of fans. The swab rod is flocked in a flock blowing mode, the flock is evenly attached to the surface of the swab rod, the flocking effect is good, only wind power needs to be provided through the fan in the flocking process, compared with an electrostatic flocking mode, the demand for electric energy is greatly reduced, the power consumption is reduced, the energy consumption is reduced, the electrostatic effect in the flocking process is also avoided, and the flocking quality is improved. The flocking effect is ensured, and the quality of the swab is ensured.

Owner:BIOTEKE CORP (WUXI) CO LTD

Bamboo flock knitwork and manufacturing process

InactiveCN101602276AImprove overall strengthIncrease profitPretreated surfacesWood layered productsColor differenceEngineering

The invention relates to a bamboo flock knitwork for bamboo window curtains, bamboo napkin, bamboo carpet, bamboo wall paper, bamboo articles, bamboo art ware, and a manufacturing method. The knitwork comprises a bamboo product, a layer of matte on the bamboo product. The bamboo knitwork has advantages that firstly the design of matte on the bamboo product not only effectively enhances the entire strength of the bamboo product, but also covers surface color difference of the bamboo product, and greatly enhances utilization of bamboo and decorative effect of the bamboo product; secondly the arrangement of bamboo surface fabric not only enhances the entire strength of the bamboo product, but also improves effect of the matte; thirdly different patterns printed on the matte according to requirements from the user not only enhances decorative effect, but also application scope of the bamboo flock knitwork.

Owner:杭州时进实业有限公司

A kind of flocking roller and flocking method thereof

InactiveCN103264009BHigh strengthIncrease elasticityLiquid surface applicatorsCoatingsPolyoxymethyleneEngineering

Owner:WUXI MEDICAL INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com