Electrostatic flocking method for automobile interior parts

A technology for automotive interior parts and electrostatic flocking, applied in the field of flocking, can solve problems such as surface shade or uneven color, health threats to construction personnel, and affect the appearance of parts, etc., to achieve high product quality and long drying time Short, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

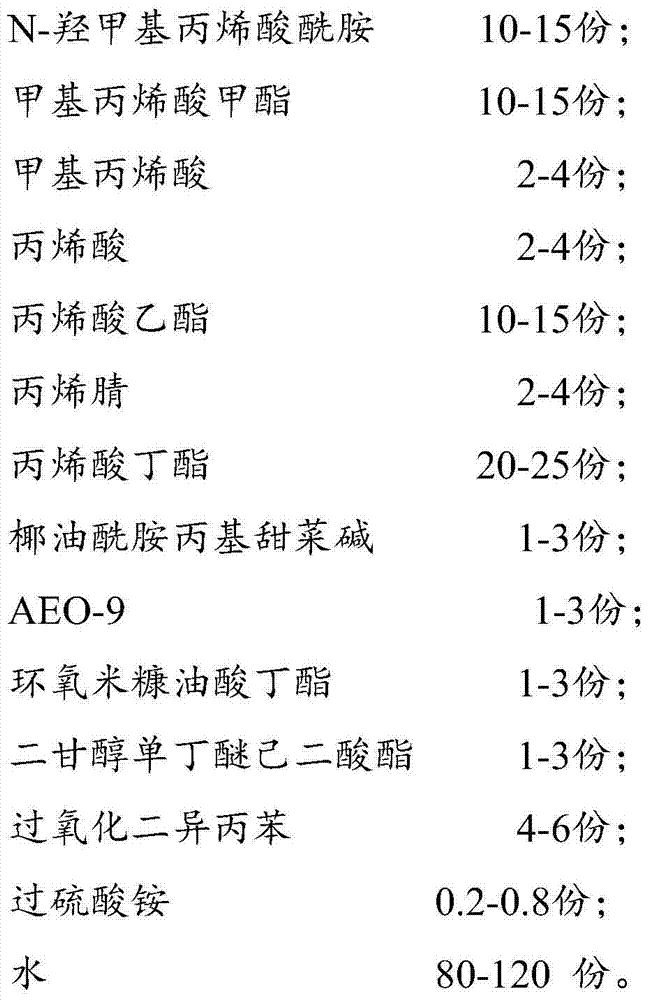

[0051] The preparation of embodiment 1 adhesive

[0052] Each raw material is taken by weighing according to the corresponding embodiment 1 data of table 1.

[0053] Stir and mix N-methylolacrylic acid amide, methyl methacrylate, methacrylic acid, acrylic acid, ethyl acrylate, acrylonitrile and butyl acrylate to obtain a monomer mixture;

[0054] Add cocamidopropyl betaine and AEO-9 into water, stir and mix evenly to obtain an emulsion;

[0055] Add the above-mentioned monomer mixture dropwise to the above-mentioned emulsion, and control the dropping time to 30-50 minutes; after the dropwise addition, continue to stir, mix evenly, and heat up to 70-80°C; then add the initiator ammonium persulfate, and stir for 1 -2 hours; Add plasticizer epoxy butyl oleate, plasticizer diethylene glycol monobutyl ether adipate and crosslinking agent dicumyl peroxide, stir for 0.5-1 hour, and cool naturally; Neutralize with ammonia water, control the final pH value at 4.5-6.0; filter to obtain ...

Embodiment 2

[0059] The preparation of embodiment 2 adhesive

[0060] Each raw material is taken by weighing according to the corresponding embodiment 2 data of table 1. Prepared by the method described in Example 1.

Embodiment 3

[0061] The preparation of embodiment 3 adhesive

[0062] Each raw material is taken by weighing according to the corresponding embodiment 3 data of table 1. Prepared by the method described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com