Oven structure for flocking machine

A technology of flocking machine and oven, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., which can solve the problems of glue solidification and affecting flocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

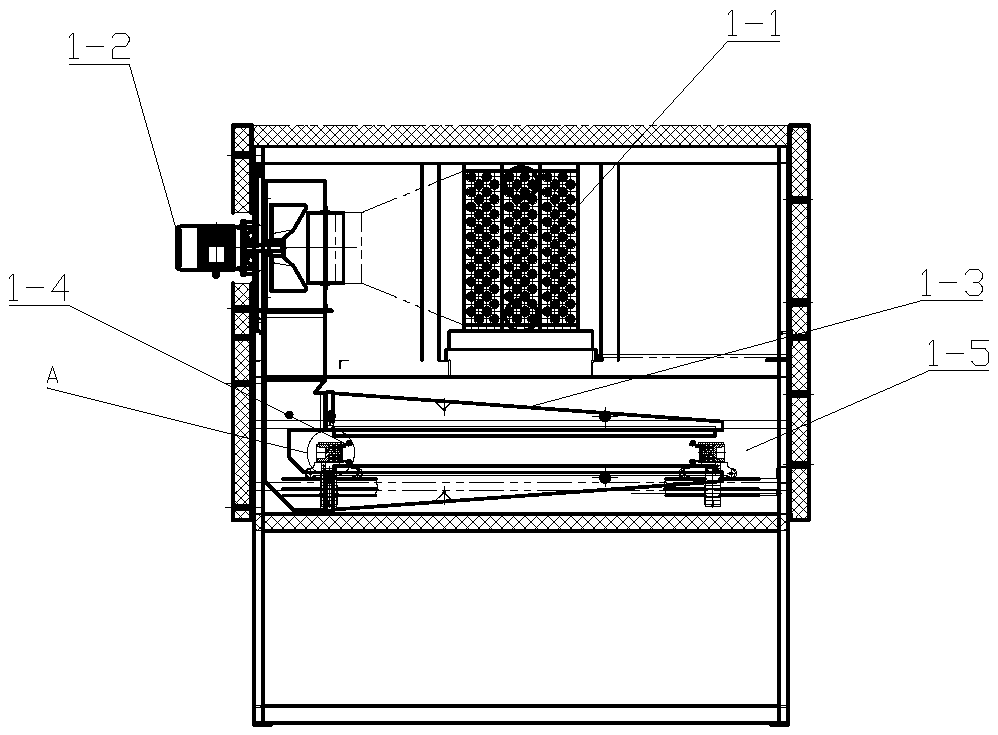

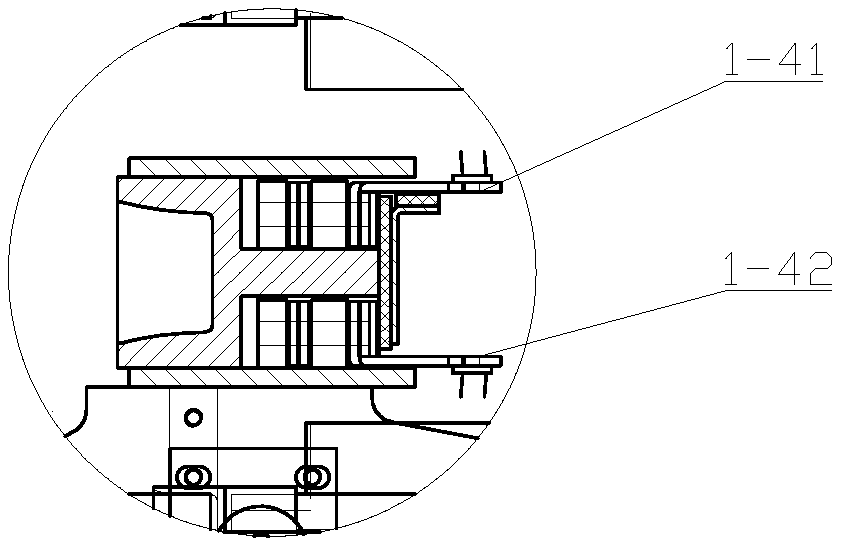

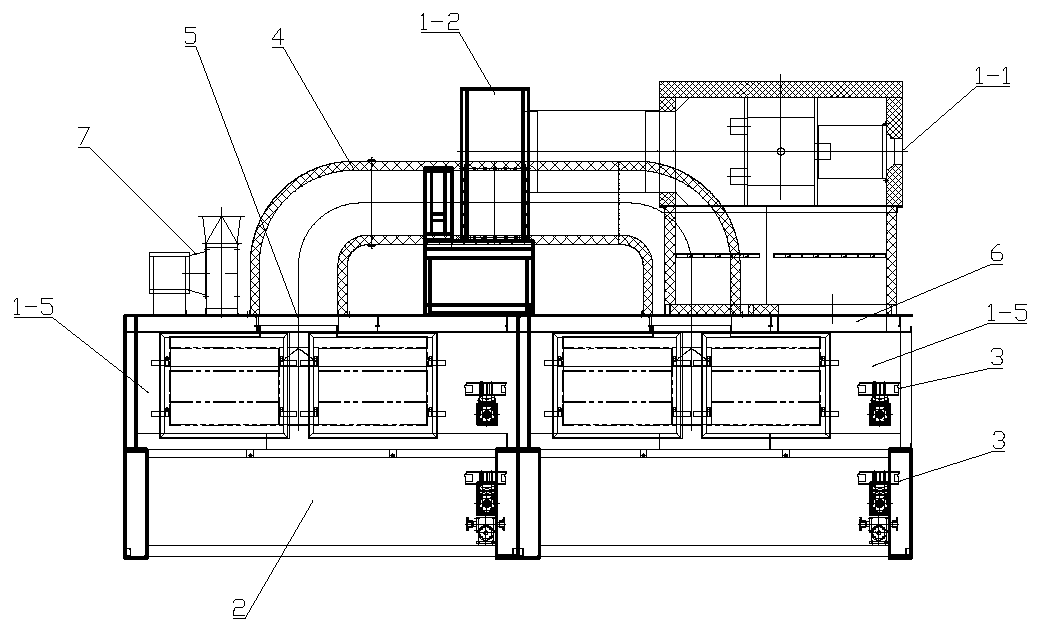

[0017] Such as image 3 , Figure 4 The shown oven structure for the flocking machine includes a heating device 1-1, a blower fan 1-2, and a heating chamber 1-5. The heating chamber 1-5 is equipped with a wind deflector 1-3, loaded with flocking The conveyor chain 1-4 of the base material is set through the heating chamber 1-5, which also includes an isolation chamber 2 separated from the heating chamber 1-5, and the conveyor chain 1 not loaded with the flocking substrate returned by the flocking machine end point -4 is set through the isolation chamber 2, the heating chamber 1-5 and the isolation chamber 2 are respectively equipped with guide rails 3 for guiding the conveyor chain 1-4, the isolation chamber 2 is located at the bottom of the heating chamber 1-5, the isolation chamber 2 and the heating chamber 1-5 are separated by insulation materials such as asbestos.

[0018] After adopting such a structure, the conveyor chain 1-4 returned by the end point of the flocking m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com