A high-efficiency flocking device for removing wrinkles of interlining

A flocking and high-efficiency technology, applied in lamination devices, lamination auxiliary operations, textiles and papermaking, etc., can solve the problems of flocking devices without wrinkle removal devices, changing the thickness of the glue layer, and not being able to recycle, etc., to achieve improved electrostatic planting velvet effect, improve flocking effect, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

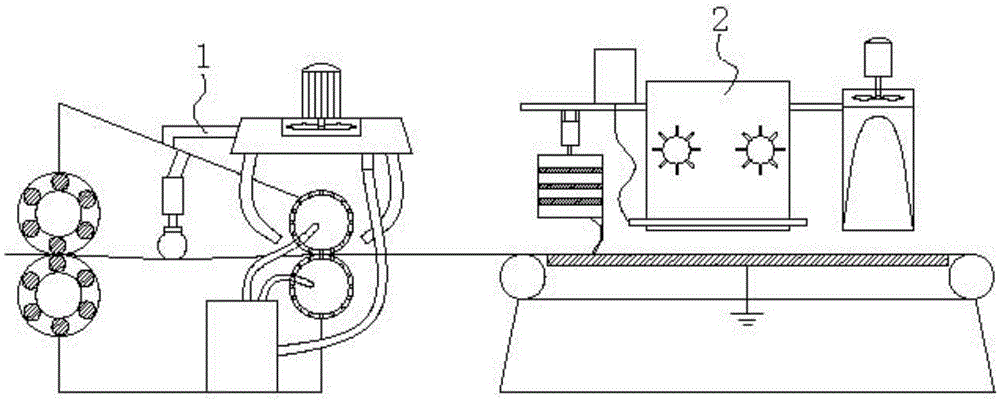

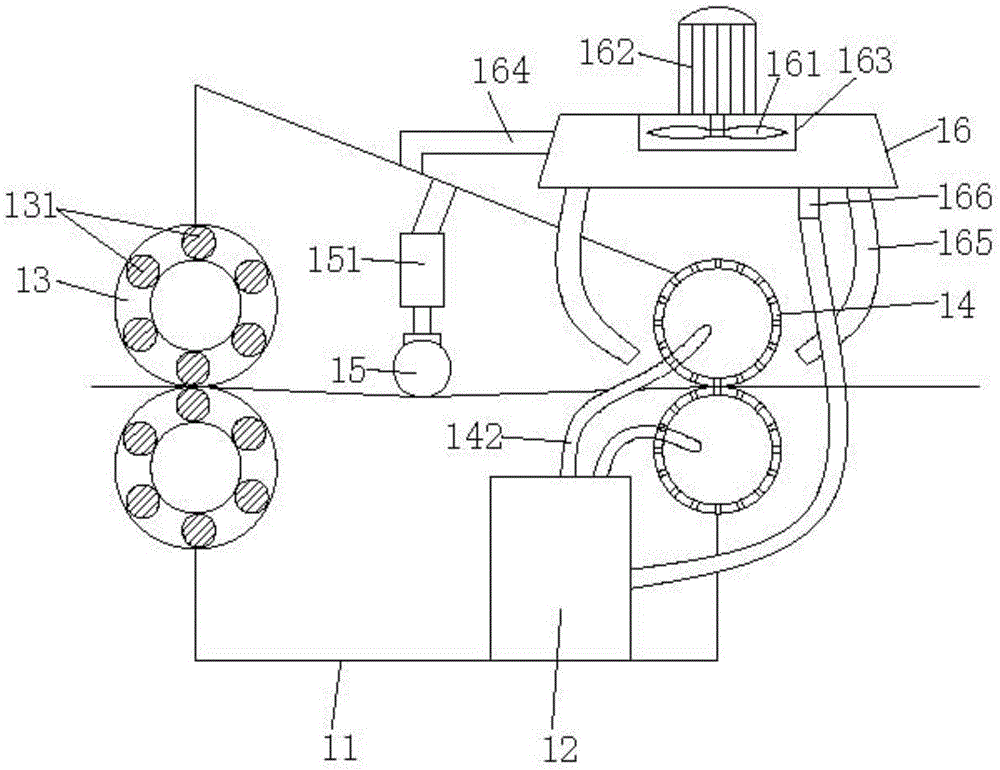

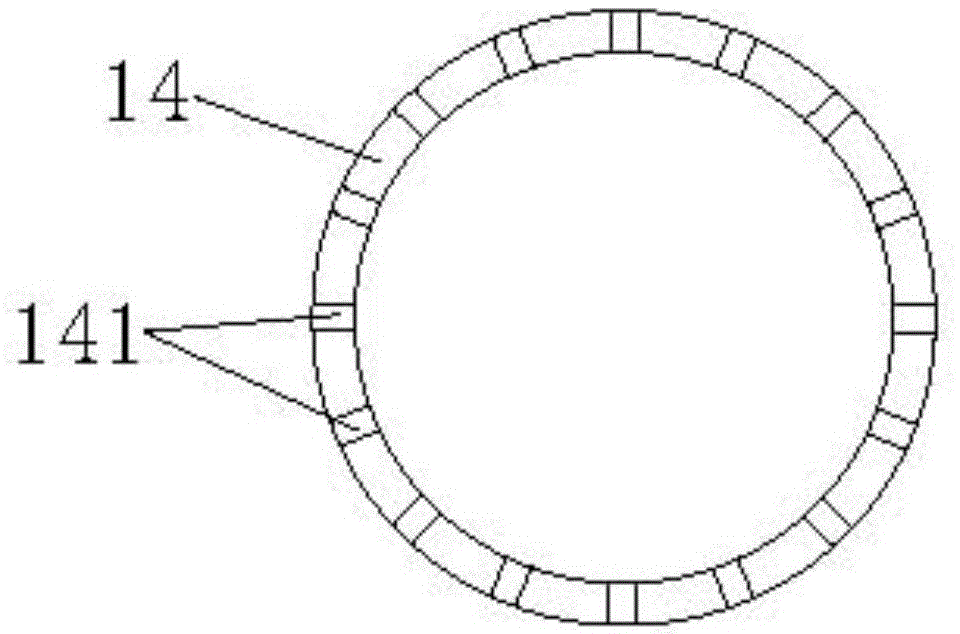

[0017] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , an interlining fabric wrinkle-removing efficient flocking device of the present invention comprises a wrinkle-removing device 1 and a flocking device 2, the wrinkle-removing device 1 is positioned at one side of the flocking device 2, and the wrinkle-removing device 1 includes a frame 11, a steam generator 12. A preheating roller 13 and a steam roller 14, the preheating roller 13 and the steam roller 14 are installed on the frame 11, a number of electric heating tubes 131 are installed inside the preheating roller 13, and the surface of the steam roller 14 is provided with Several steam through holes 141, the steam roller 14 is connected with the steam generator 12 through the gas delivery pipe 142, a pinch roller 15 is arranged between the preheating roller 13 and the steam roller 14, and the pinch roller 15 passes through the first lift Cylinder 151 is installed on the frame 11, and exhaust hood ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com