Spunlace flocking device and method

A flocking and spunlace technology, used in needle punching machines, textiles and papermaking, non-woven fabrics, etc., can solve the problem of insufficient waterproofness and bonding strength, increase equipment cost and material cost, floor space and space Increase and other problems to achieve the effect of low manufacturing cost, saving material and equipment cost, and reducing labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

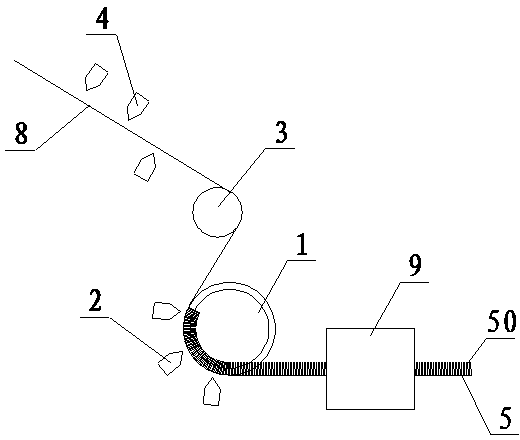

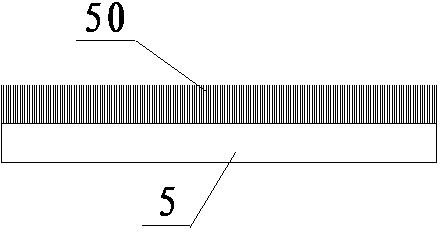

[0022] Embodiment 1: with reference to attached figure 1 , 2 , with processing attached figure 2 Take the non-woven fabric 5 with fluff 50 as an example. A spunlace flocking method, comprising the following steps,

[0023] ①Using fine denier fiber as raw material, the fiber web 8 formed in the forming net is transported to the spunlace machine through the transmission device, and the high-pressure spunlace head 4 is used for spunlace entanglement on the front and back sides;

[0024] ②After the spunlace reinforcement is completed, the fiber web 8 is transferred to the flocking drum 1 with tiny holes under the action of the transition drum 3;

[0025] ③ A plurality of high-pressure flocking spunlace heads 2 installed on the outside of the flocking drum 1 spray high-pressure fine water flow, and flush one end of the fiber on the fiber web 8 into the tiny holes of the flocking drum 1;

[0026] ④ Separate the flocked fiber web 8 from the flocking drum 1. At this time, the fib...

Embodiment 2

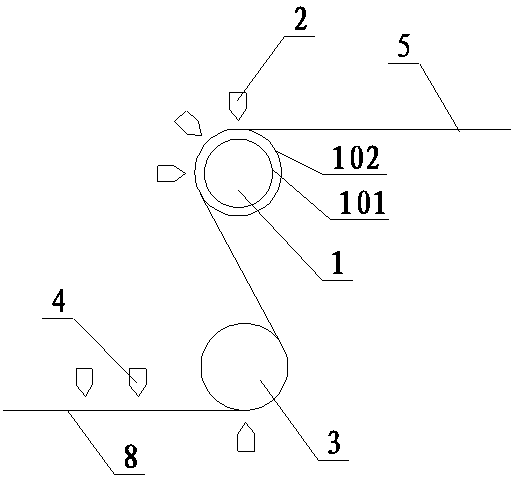

[0028] Embodiment 2: with reference to attached figure 2 , 3 , 4, with processing attached figure 1 Take the finished flocking non-woven fabric as an example. A spunlace flocking device, comprising a flocking drum 1, a plurality of high-pressure flocking spunlace heads 2 installed on the outside of the flocking spun drum 1, and a plurality of high-pressure flocking spunlace heads 2 arranged in a ring around the The outer side of the flocking drum 1; the flocking drum 1 has a plurality of tiny holes 7; the flocking drum 1 is composed of an outer layer nickel mesh 102 and an inner layer steel mesh 101; the outer layer nickel mesh 102 and the inner steel mesh 101 are uniformly arranged with a plurality of tiny holes 7; a transition drum 3 is provided between the hydroentanglement head 4 and the flocking drum 1 in the hydroentanglement process; 8 After the hydroentanglement and reinforcement of the hydroentanglement head 4, it is transported to the flocking drum 1 through the ...

Embodiment 3

[0029] Embodiment 3: with reference to attached figure 2 , 5 , with processing attached figure 1 Take the finished flocking non-woven fabric as an example. A spunlace flocking device, comprising a flocking trawl curtain 6, a plurality of high-pressure flocking spunlace heads 2 installed on the outside of the flocking trawl curtain 6, and a plurality of high-pressure flocking spunlace heads 2 evenly arranged on the The outer side of the velvet trawl curtain 6; the flocking trawl curtain 6 has a plurality of tiny holes 7; the flocking trawl curtain 6 is composed of an outer layer nickel mesh 601 and an inner layer nickel mesh 602 combined structure; the outer layer nickel mesh 601 and the inner nickel mesh 602 are evenly arranged with a plurality of tiny holes 7; a plurality of transition drums 3 are arranged between the hydroentanglement head 4 and the flocking trawl curtain 6 in the hydroentangling process; After the fiber web 8 is entangled and strengthened by the hydroen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com