Hydrophobic and bacteriostatic multifunctional coating fabric and preparation method thereof

A multi-functional coating and hydrophobic technology, applied in the textile field, can solve the problems of uneven coating, poor hydrophobic and bacteriostatic performance, insufficient coating adhesion firmness, etc., and achieve high adhesion firmness, excellent hydrophobic bacteriostatic performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

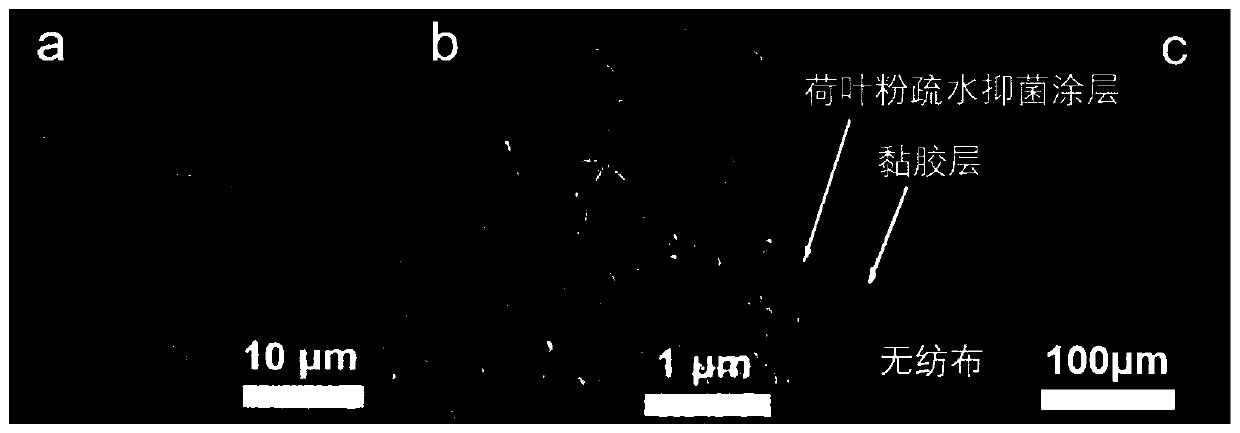

[0056] Embodiment 1 provides a kind of hydrophobic and antibacterial multifunctional coated cloth, including non-woven fabric and lotus leaf powder hydrophobic and antibacterial coating coated on the non-woven fabric by electrostatic flocking method.

[0057] Wherein, the electrostatic flocking amount of the lotus leaf powder hydrophobic antibacterial coating is 100g / m 2 The thickness of the hydrophobic antibacterial coating of the lotus leaf powder is 1.5mm; the particle size of the lotus leaf powder is 150nm.

[0058] The preparation method of described a kind of hydrophobic antibacterial multifunctional coated cloth, comprises the steps:

[0059] S1. Electrostatic treatment of lotus leaf powder: choose lotus leaf powder of predetermined specifications for electrolytic treatment;

[0060] S2, gluing: heat the hot melt adhesive to melt, and then apply the melted hot melt adhesive on the outer surface of the non-woven fabric to form an adhesive layer; the coating amount of th...

Embodiment 2-5

[0066] Embodiment 2-5 provides a kind of hydrophobic and bacteriostatic multifunctional coated cloth, compared with embodiment 1, the difference is that in the preparation method step S2 of the described hydrophobic and bacteriostatic multifunctional coated cloth, the Except for the above differences, other operations are the same for the coating amount of the above-mentioned hot melt adhesive, and will not be repeated here; the specific experimental conditions, parameters and measurement results are shown in the table below.

[0067]

[0068] It can be seen from the results in the above table that when the coating amount of the hot melt adhesive is less than 200g / m 2 When the flocking density and fastness of the lotus leaf powder and the antibacterial performance of the multi-functional coated cloth are poor, when the coating amount of the hot melt adhesive is greater than 250g / m 2 , the flocking density and fastness of lotus leaf powder, the hydrophobicity and the antibac...

Embodiment 6-9

[0070] Embodiment 6-9 provides a kind of hydrophobic and bacteriostatic multifunctional coated cloth, compared with embodiment 1, the difference is that in the preparation method step S3 of the described hydrophobic and bacteriostatic multifunctional coated cloth, the In addition to the above differences, the other operations are the same as the above-mentioned flocking indoor pole plate spacing, and will not be repeated here; the specific experimental conditions, parameters and measurement results are shown in the table below.

[0071]

[0072]

[0073] Comparing the results of Example 1 and Examples 6 to 9 in the table, it can be seen that with the increase of the distance between the pole plates, the flocking density and fastness of the lotus leaf powder generally show a downward trend, but within the distance between the pole plates less than 15cm, It has little effect on the flocking density and fastness of lotus leaf powder, and when the distance between the plates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com