A processing technology of flocking tag and automatic heat press machine used in the technology

A processing technology, heat press machine technology, applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of paper substrates not easy to degrade, resource waste environment, complex production process, etc., to achieve the improvement effect , save production cost, and the effect of simple processing procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: a kind of processing technology of flocking tag, comprises the following steps:

[0043] Step S1, pulping the cardboard: Cover the surface of the cardboard with a glue coating film, and a glue coating groove is opened on the glue coating film. Flock pulp additives, and add appropriate amount of water and stir it, so that the flocking pulp has a good viscosity, apply the flocking pulp evenly on the glue groove of the glued film with a glue brush, and apply it to the cardboard Glue the part that needs to be flocked on the surface. After the glue is applied, tear off the glued film and let the cardboard stand for 1 to 2 hours to make the flocking glue dry and solidify. During the standing process, you can use equipment such as a hot air blower Accelerate its drying and curing process. After the flocking glue is completely cured, it can be stored, and it can be taken out for processing when it is necessary to produce hang tags.

[0044] Step S2, compounding o...

Embodiment 2

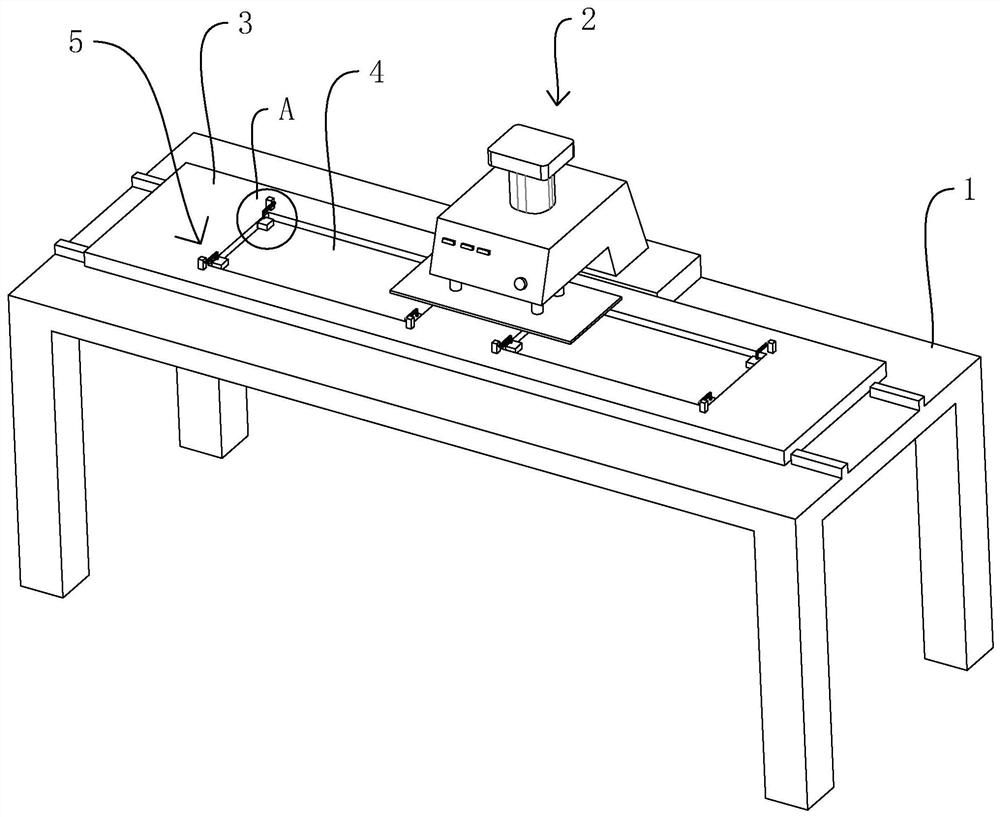

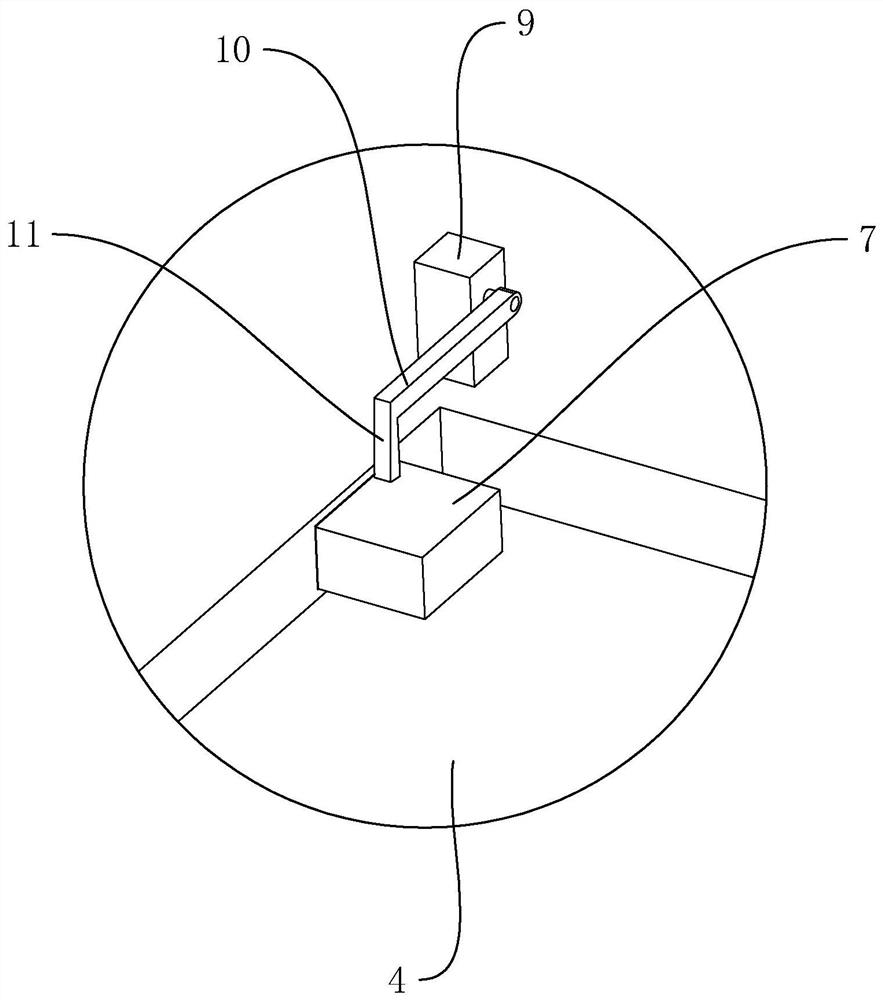

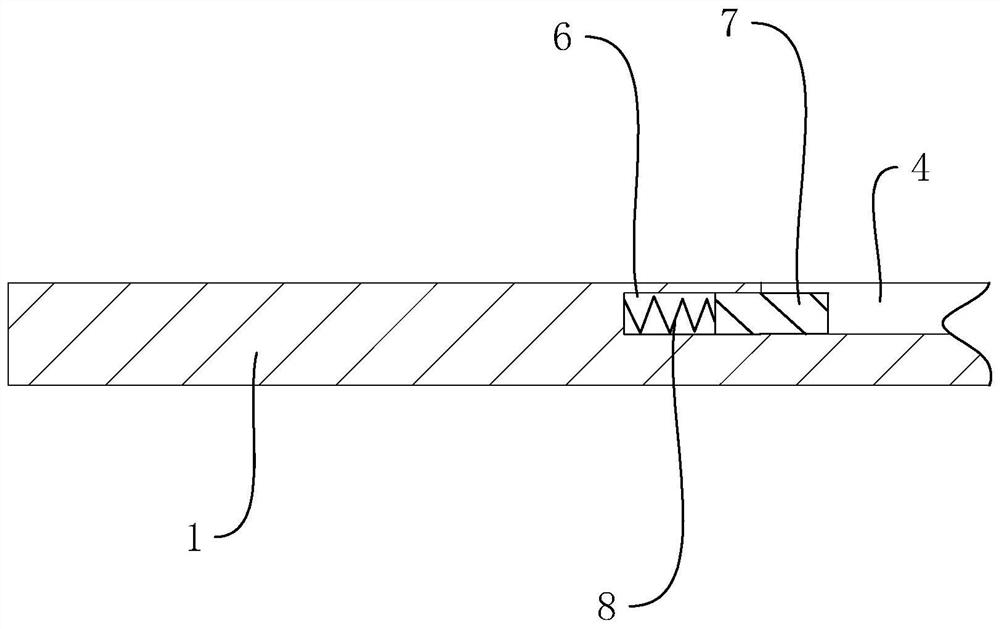

[0048] Embodiment 2: refer to figure 1 , a heat press machine, including a workbench 1 and a heat press assembly 2 arranged above the workbench 1, the upper surface of the workbench 1 is slidably connected with a discharge plate 3, and the two ends of the upper surface of the discharge plate 3 are provided with Two discharge troughs 4, the depth of the discharge chute 4 is less than the thickness of the processed cardboard, the two sides of the discharge chute 4 are provided with positioning components 5 for positioning the cardboard, and the cardboard and flocking board are combined and placed in the discharge In the tank 4, it is positioned by the positioning component 5, and it is pushed into the bottom of the heat press component 2 for hot pressing. During the hot pressing time, the material can be loaded into the discharge tank 4 at the other end After the hot pressing is completed, slide the discharge plate 3 so that the discharge trough 4 at the other end is located und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com