Worktable of hair planting machine

A workbench and tufting machine technology, applied in brushes, household utensils, applications, etc., can solve problems such as low processing efficiency, difficult tufting, and limited adjustment positions, and achieve increased adjustment range, significant stability, and large adjustment range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

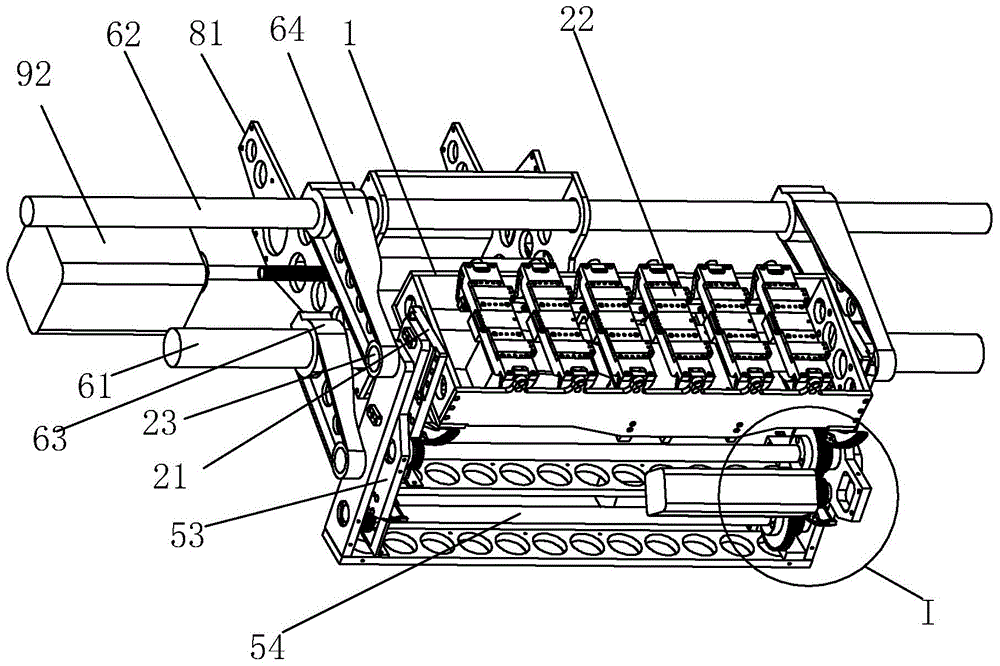

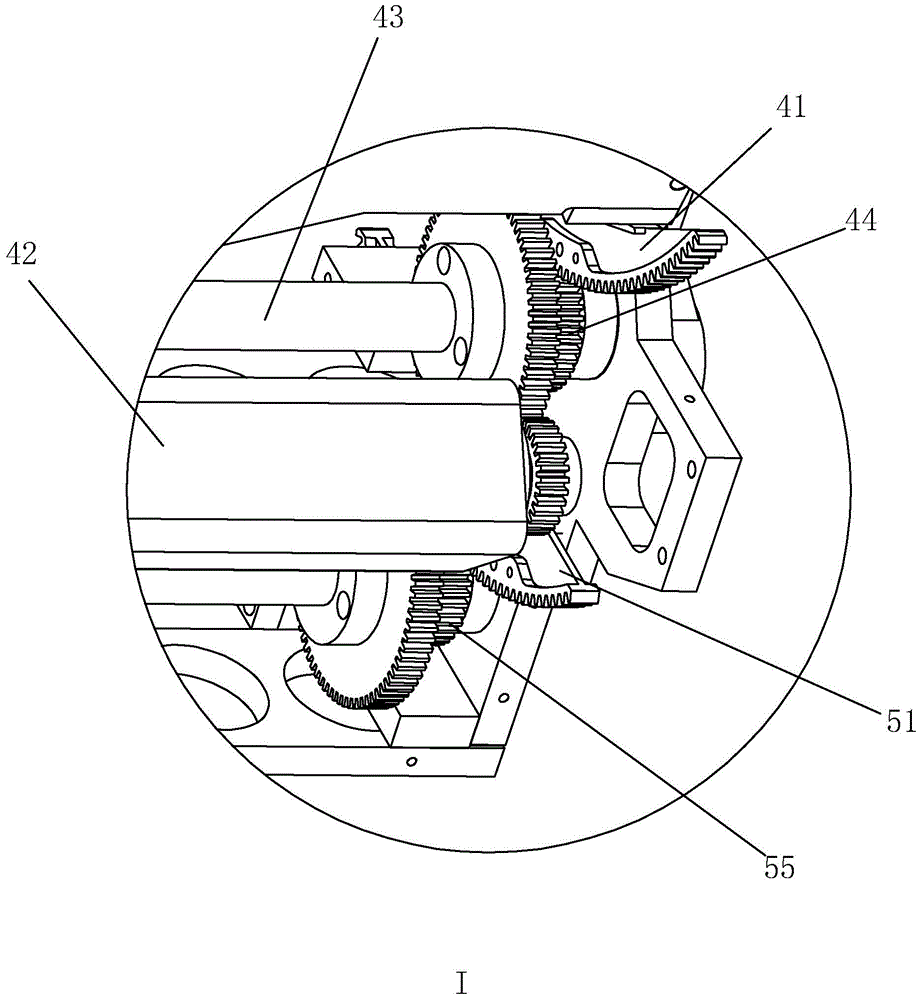

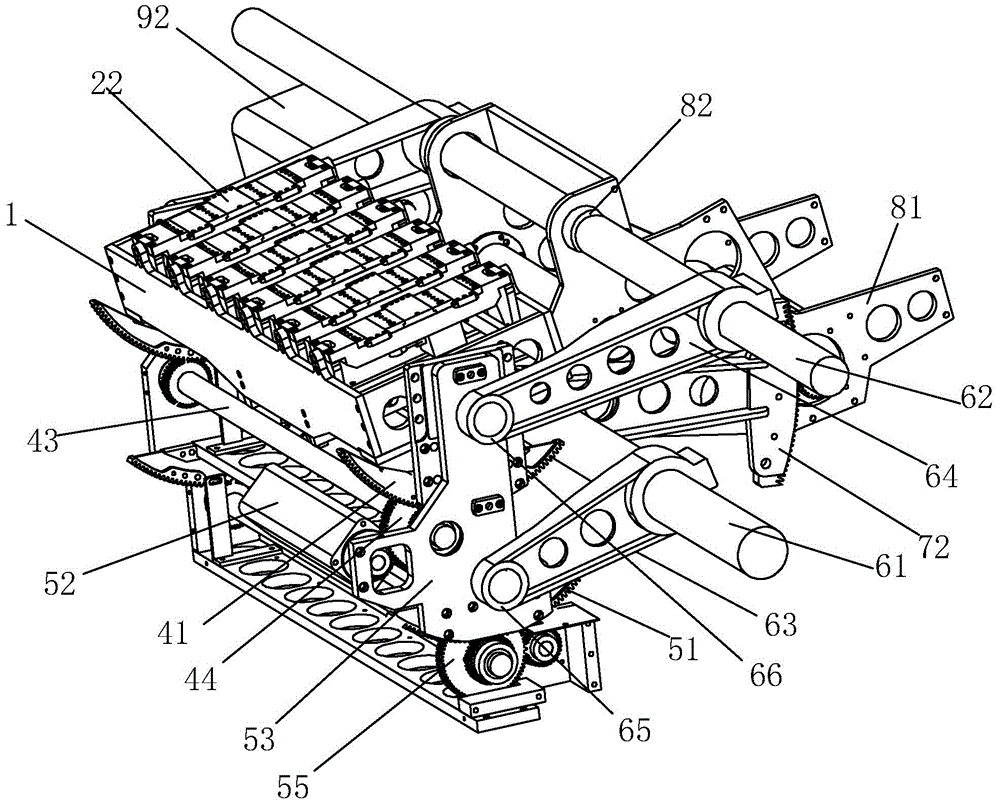

[0028] refer to Figure 1 to Figure 8 Further description will be given to the embodiment of the workbench of the tufting machine of the present invention.

[0029] A hair-planting machine workbench, comprising a frame body 1, a support plate 21, a clamp table 22 and a support mechanism, the support plate 21 is supported by a support mechanism, the clamp platform 22 is located on the frame body 1, and the support plate 21 is A fixed shaft 23 is provided, and the fixed shaft 23 passes through the frame body 1, and a first rotating shaft 24 is pierced in the clamp table 22, and the clamp table 22 is rotationally connected with the frame body 1 through the first rotating shaft 24, and the The fixture table 22 is provided with a first drive device that drives it to rotate around the first rotating shaft 24, and the second drive device that drives the frame body 1 to rotate around the fixed shaft 23 is provided on the support plate 21. There is a third driving device that drives i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com