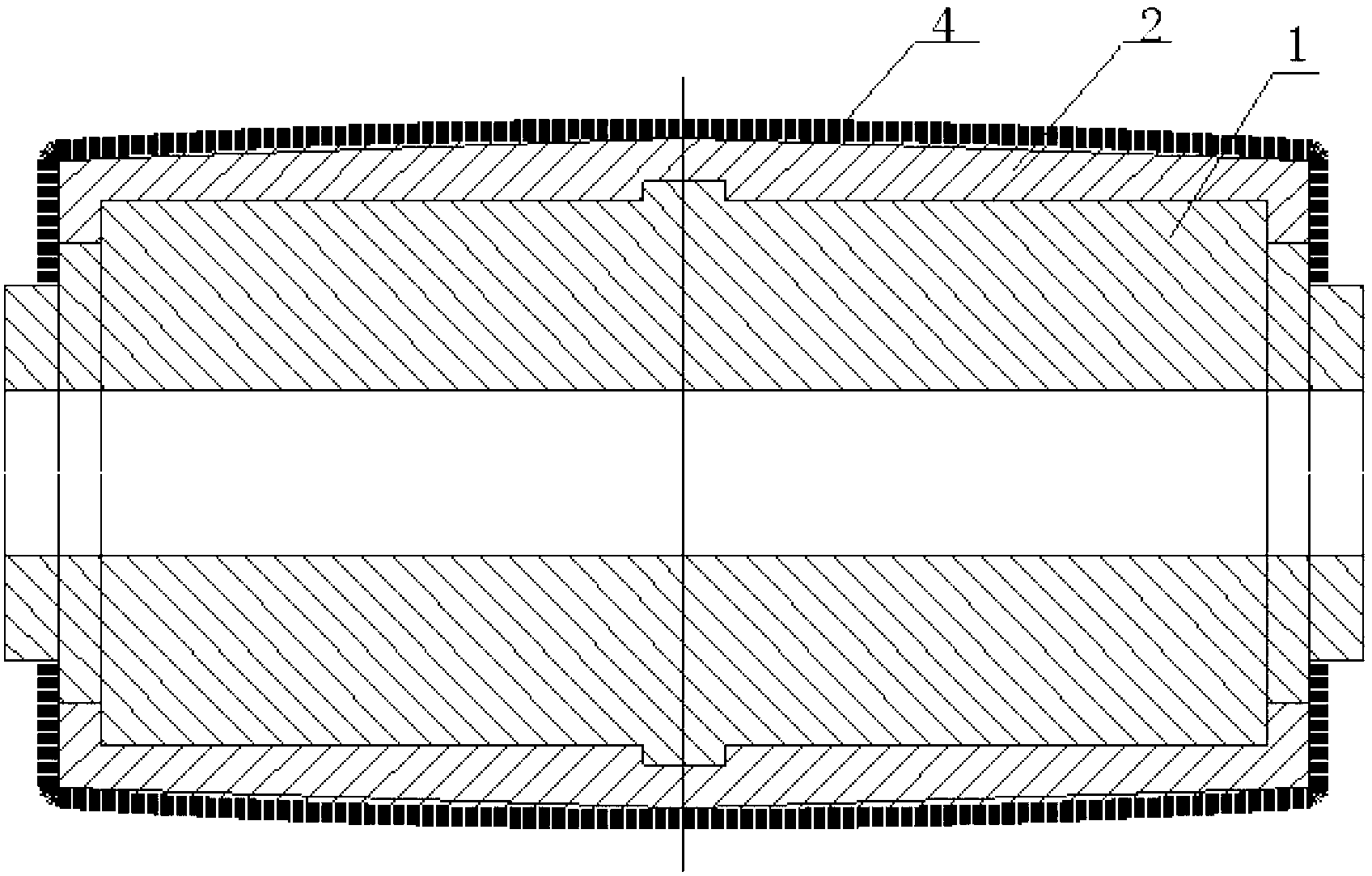

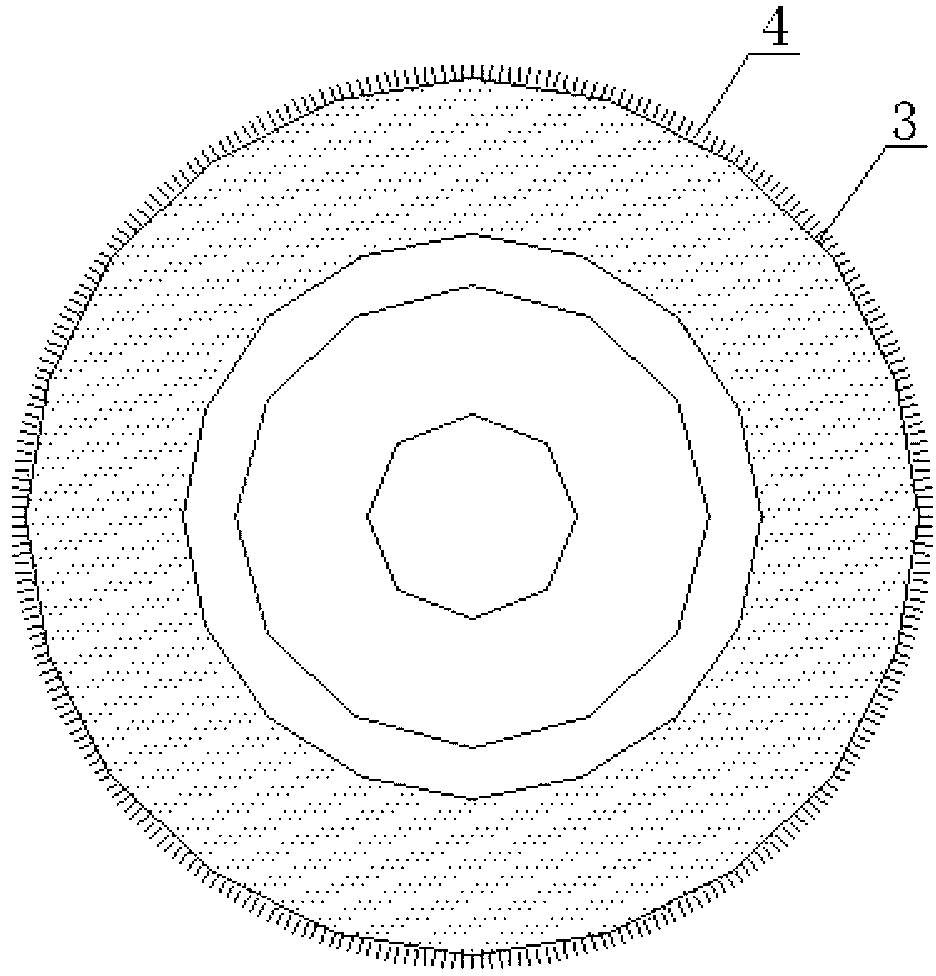

Flocking roller and flocking method thereof

A technology of flocking and rollers, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of decreased fluff smoothness, high cost, and difficulty in cleaning, and achieves good shock absorption and noise reduction. Good grinding performance and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] To make a batch of flocking rollers with a length of 3cm, the steps are as follows:

[0028] (1) POM heated and softened at a temperature of 200 degrees is injected into the mold through an injection molding machine and cooled to obtain a POM wheel core with a size of 3 cm.

[0029] (2) Light wheel preparation and surface treatment: put the raw material POM into the injection mold, then add PVC softened at a temperature of 160-180°C to wrap it on the surface, and shape it into a light wheel after cooling, and select 3.5 The POM core between ~4.5cm, the surface of these light wheels is cleaned, and each light wheel after cleaning is penetrated into a custom-made conductive fixture, and a layer of adhesive is coated on the surface of each light wheel to form a package. Adhesive layer, until the adhesive layer is uniform and smooth without air holes, the thickness of the adhesive layer is 0.2-0.3mm, and finally the conductive fixture is grounded;

[0030] (3) Flocking: Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com