Flocked bra fabric production equipment and production technology

A production equipment and technology for bras, which are applied to bras, pretreatment surfaces, and devices for coating liquids on surfaces, etc., which can solve various needs of flocking fabrics, weak adhesion of fabric fluff, and inability to meet industrial production, etc. problem, to achieve the effect of low labor intensity, strong three-dimensional effect and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

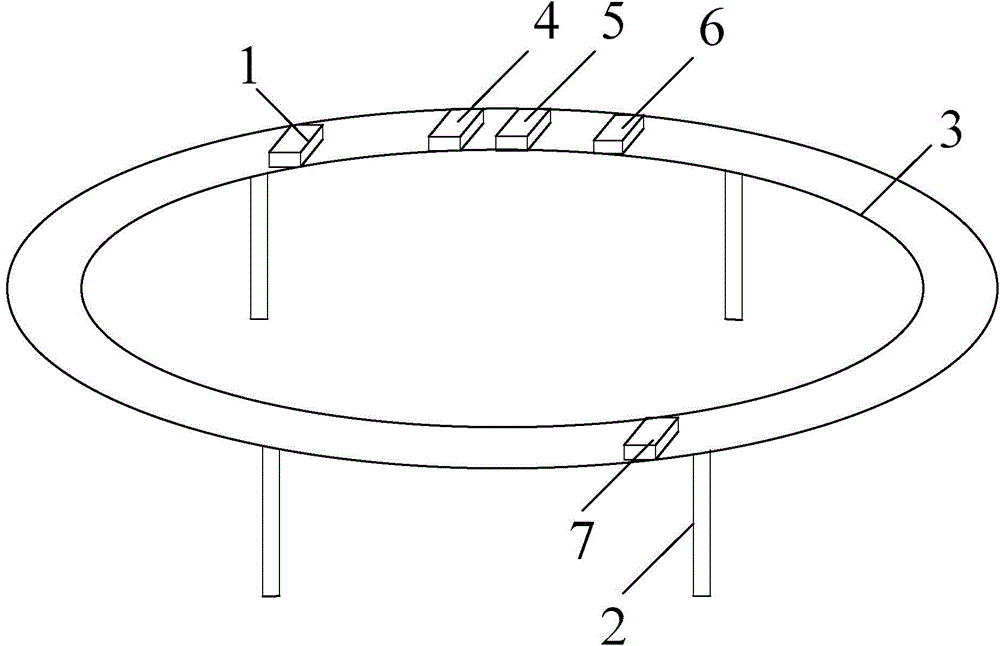

[0022] Such as figure 1 with figure 2 As shown, a flocking bra fabric production equipment of the present invention includes a control device 1 and a frame 2, the frame 2 is provided with a transmission device 3 for transmitting bra fabrics, and the transmission device 3 is fixedly installed on the top There are a first automatic glue scraper 4, a first dryer 5, a second automatic glue scraper 6 and an automatic flocking device 7; the flocking bra fabric production equipment also includes a second dryer 8 which is set independently.

[0023] The control device 1 is arranged on the frame 2 .

[0024] The automatic flocking device 7 is an electrostatic flocking machine. When the electrostatic flocking machine is powered on, a high-voltage electric field is formed in the electrostatic flocking machine, so that the fluff has great straightness and flying in the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com