A puller for removing a fixed nozzle of a small aero-engine and its application method

A technology of aero-engines and nozzles, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of operators being injured by dumping, affecting the quality and efficiency of engine disassembly and recovery assembly, and jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below.

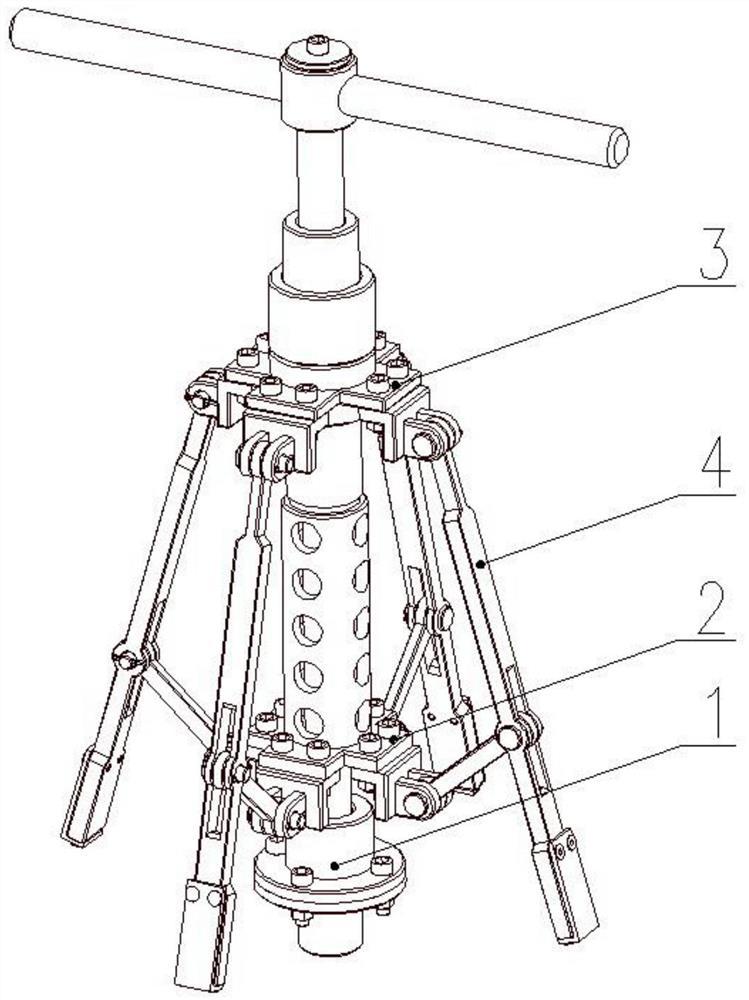

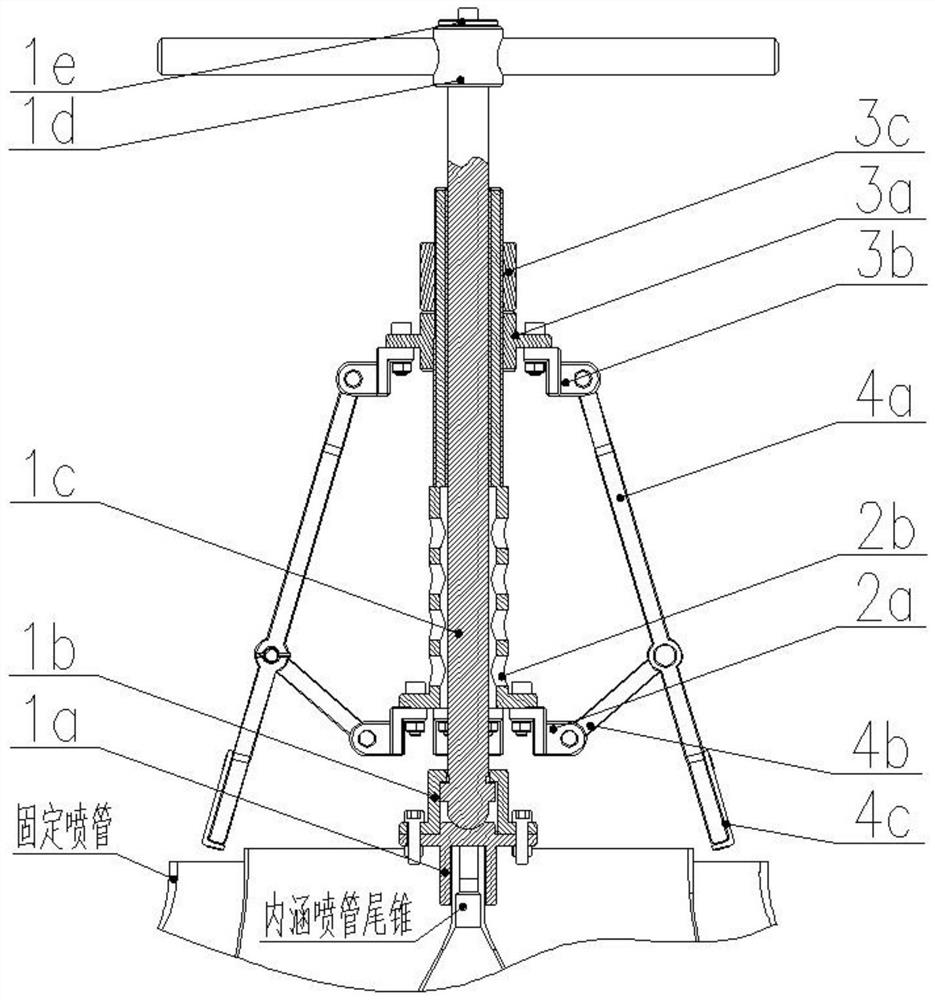

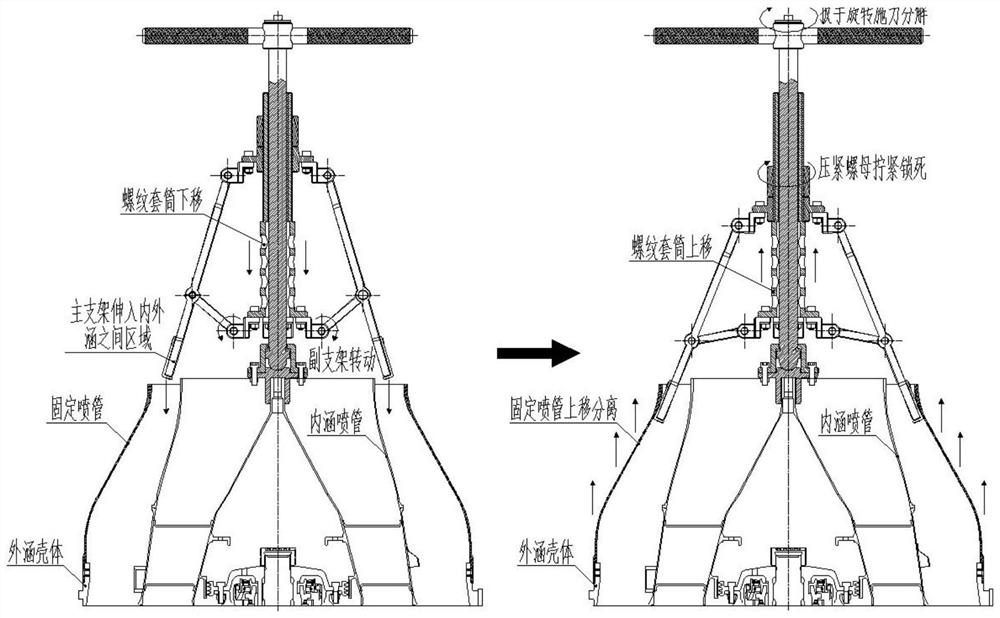

[0031] see figure 1 , is a structural schematic diagram of a puller for removing a fixed nozzle of a small aero-engine provided by an embodiment of the present invention. Such as figure 1 As shown, the small aero-engine fixed nozzle removal puller includes:

[0032] The supporting screw assembly 1 includes a screw 1c and a spherical base 1a fixed on the bottom of the screw 1c, and the spherical base 1a is set on the inner nozzle tail cone of the engine;

[0033] The lower slider assembly 2 includes a threaded sleeve 2b and a plurality of first external brackets 2a, the threaded sleeve is sleeved on the screw 1c, and one end of the external bracket is connected to the threaded sleeve;

[0034] The upper slider assembly 3 includes a sliding sleeve 3a and a plurality of second external brackets 3b, the sliding sleeve 3a is slidably sleeved on the threaded sleeve 2b, and one end of the second external bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com