Large-breadth conduction band UV digital printer

A printer and large-format technology, applied in printing devices, printing, etc., can solve the problems of reduced printing accuracy and large gap between nozzle holes, and achieve the effects of improving installation accuracy, production efficiency, and installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

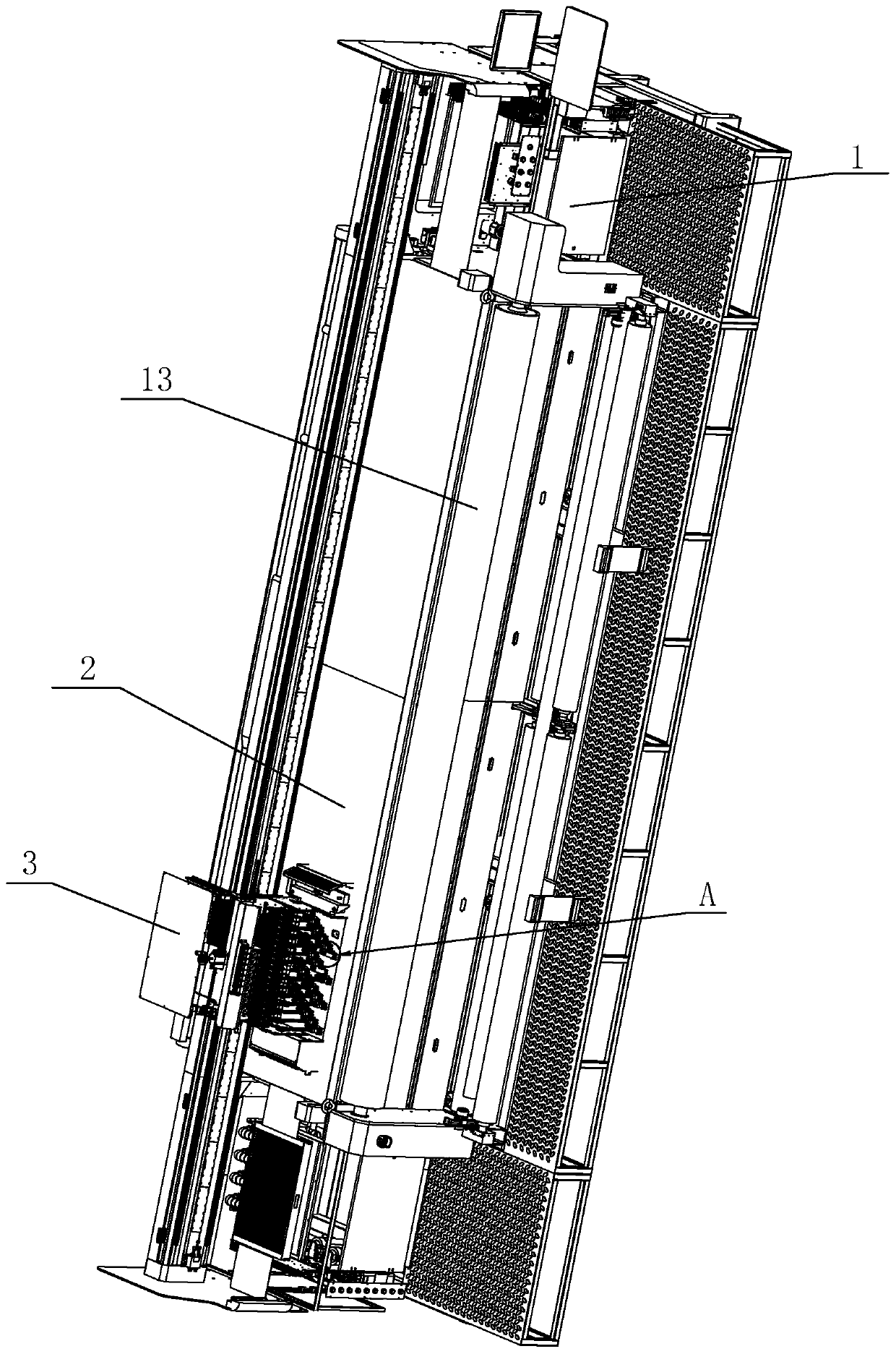

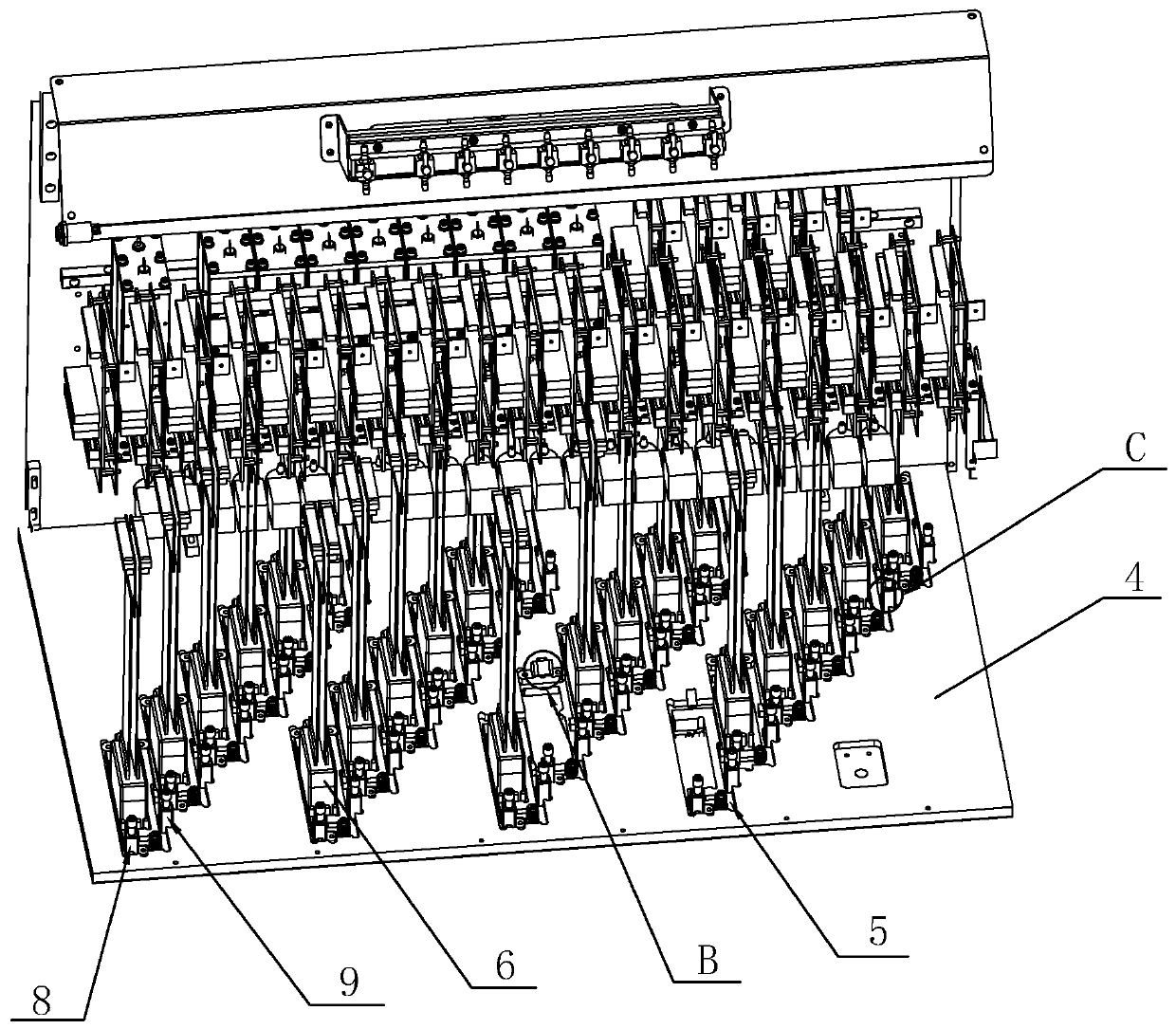

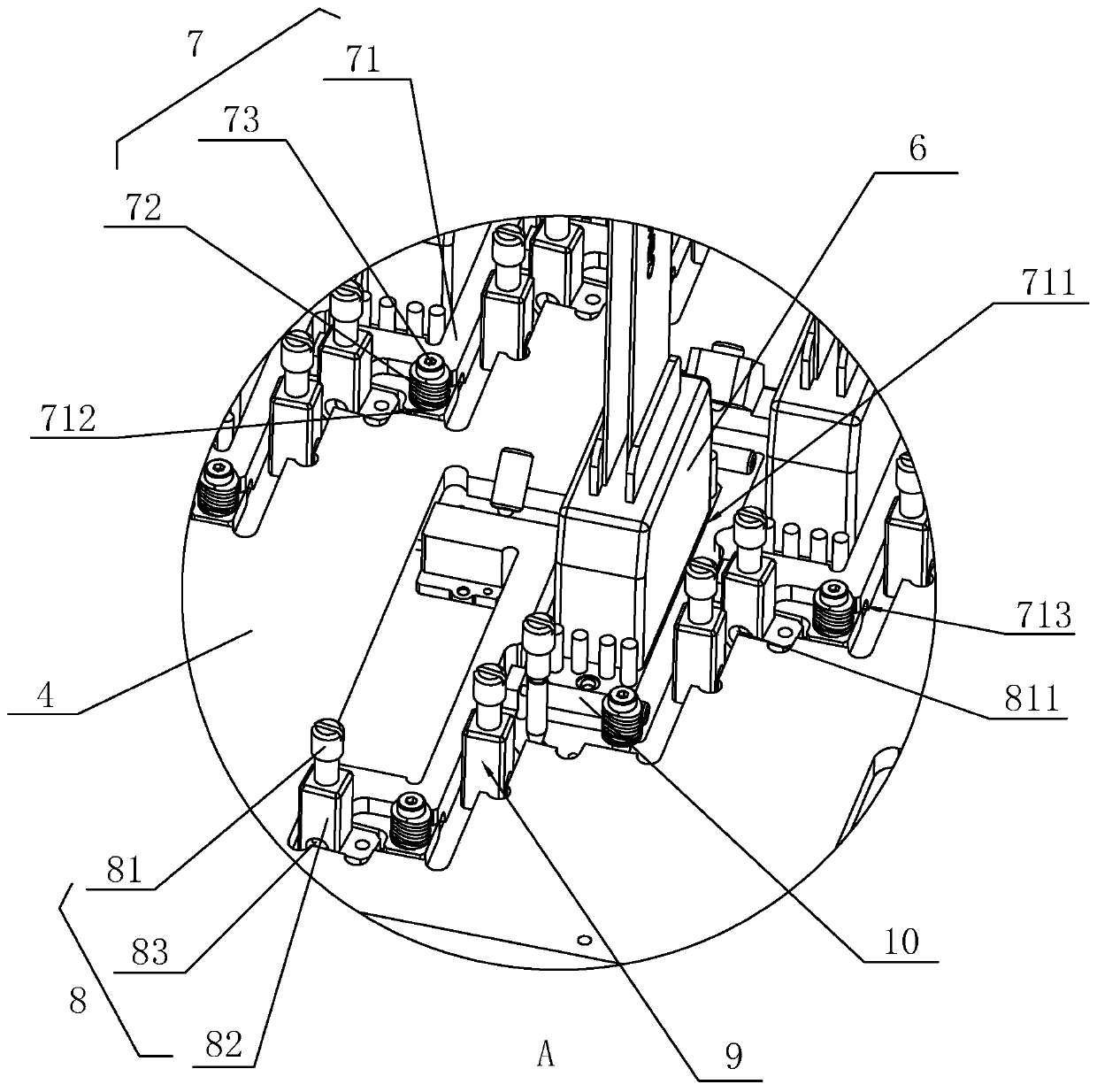

[0035] Such as figure 1As shown, a large-format UV digital printer with a guide belt includes a printer body 1. Two printing platforms 2 of the same size and structure are detachably installed on the printer body 1. The two printing platforms 2 are aligned and assembled to expand the printer body 1. print format. The adjacent position of printing platform 2 is rotatably connected with conveying roller 13, and the printer body 1 is slidably connected with nozzle moving frame 3, which reciprocates along the length direction of printer body 1, and the nozzle moving frame 3 is installed with nozzle 6. The bottom plate 4 and the conveying roller 13 transport the object to be printed on the printing platform 2 , and the nozzle moving frame 3 drives the nozzle 6 to move back and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com