Method and device for measuring free-form surface with large inclination angle based on comparative measurement of reference plane

A technology of comparative measurement and reference plane, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of surface roughness, fluctuations, and inclination angles of measurement accuracy samples, so as to improve the measurable range and accuracy , the effect of reducing the Abbe error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

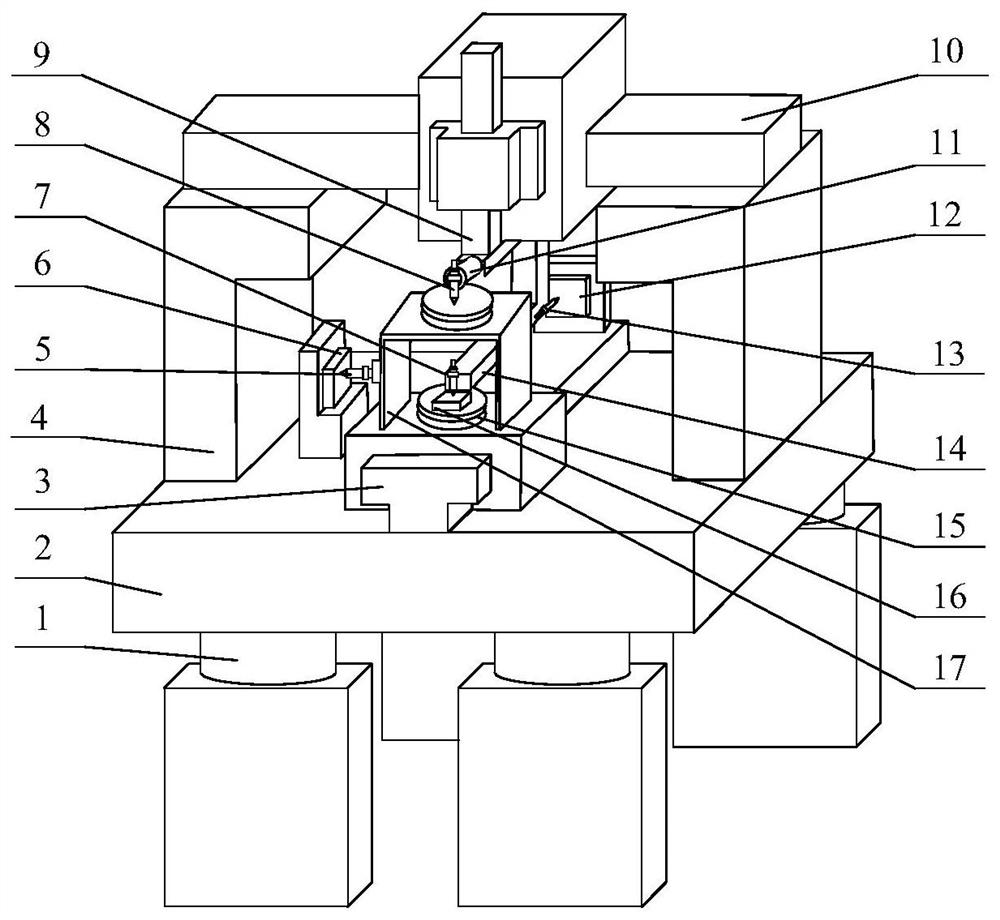

[0038] like figure 1 As shown, a large-inclination free-form surface measurement device based on the comparison measurement of the reference plane, including: active air-flotation isolation spring 1, air-flotation isolation base 2, X-direction air-flotation guide rail 3, gantry frame 4, the first nanometer Precision height measurement sensor 5, first flat crystal 6, second nanometer precision height measurement sensor 7, third nanometer precision height measurement sensor 8, Z direction air bearing guide rail 9, Y direction air bearing guide rail 10, air bearing shaft 11, The second flat crystal 12 , the fourth nanometer precision height measuring sensor 13 , the truss 14 , the reference flat crystal attitude adjustment device 15 , the third flat crystal 16 , and the support frame 17 .

[0039] The connection and positional relationship of the above components are:

[0040] The air flotation isolation base 2 is installed on the active air flotation isolation spring 1; the X-d...

Embodiment 2

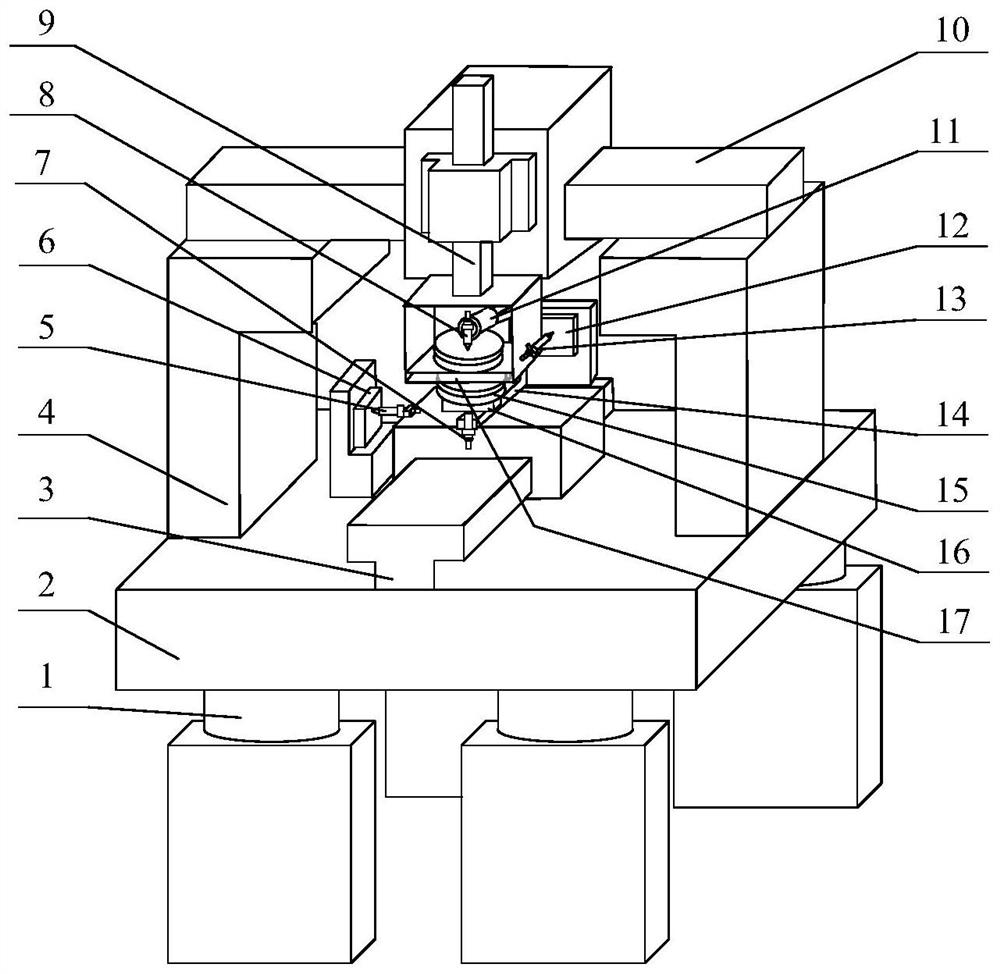

[0048] like figure 2 As shown, a large-inclination free-form surface measurement device based on the comparison measurement of the reference plane, including: active air-flotation isolation spring 1, air-flotation isolation base 2, X-direction air-flotation guide rail 3, gantry frame 4, the first nanometer Precision height measurement sensor 5, first flat crystal 6, second nanometer precision height measurement sensor 7, third nanometer precision height measurement sensor 8, Z direction air bearing guide rail 9, Y direction air bearing guide rail 10, air bearing shaft 11, The second flat crystal 12 , the fourth nanometer precision height measuring sensor 13 , the truss 14 , the reference flat crystal attitude adjustment device 15 , the third flat crystal 16 , and the support frame 17 .

[0049] The connection and positional relationship of the above components are:

[0050] The air flotation isolation base 2 is installed on the active air flotation isolation spring 1; the X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com