Automobile gear shifting handle combined switch assembly

A combination switch and automobile gear shifting technology, applied in electrical components and other directions, can solve the problems of high waterproof requirements and high manufacturing costs, and achieve the effect of reducing waterproof requirements, reducing production costs, and avoiding damage to the environment and human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

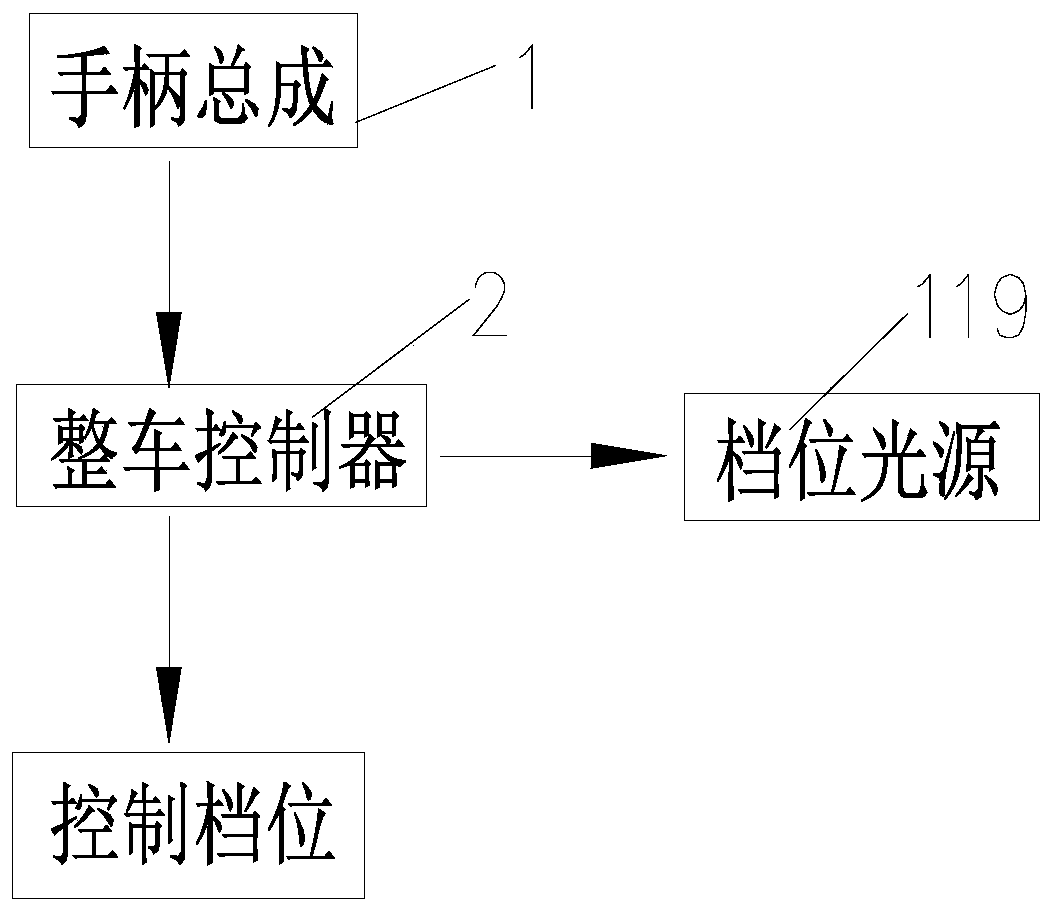

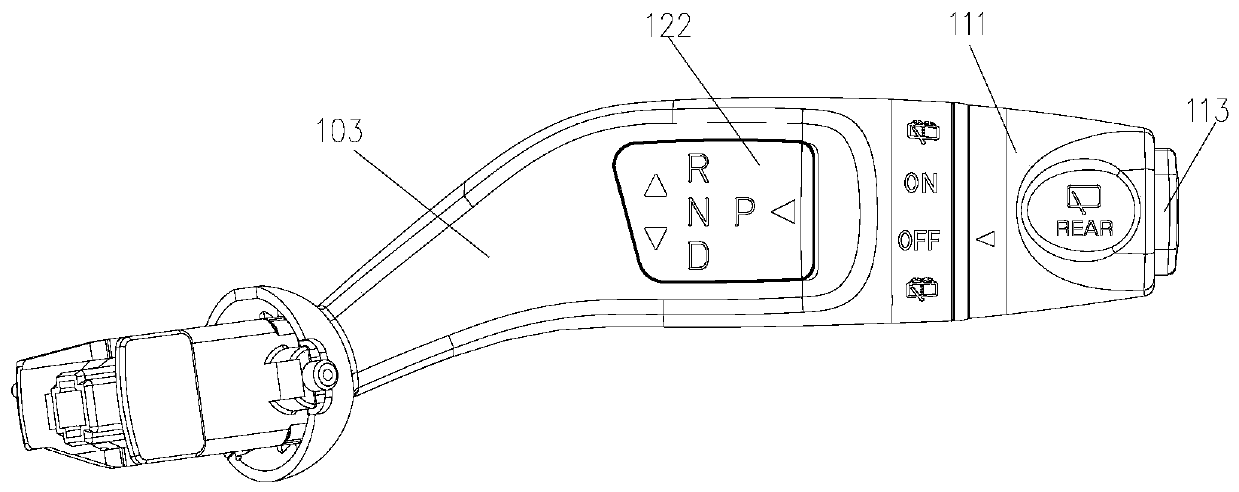

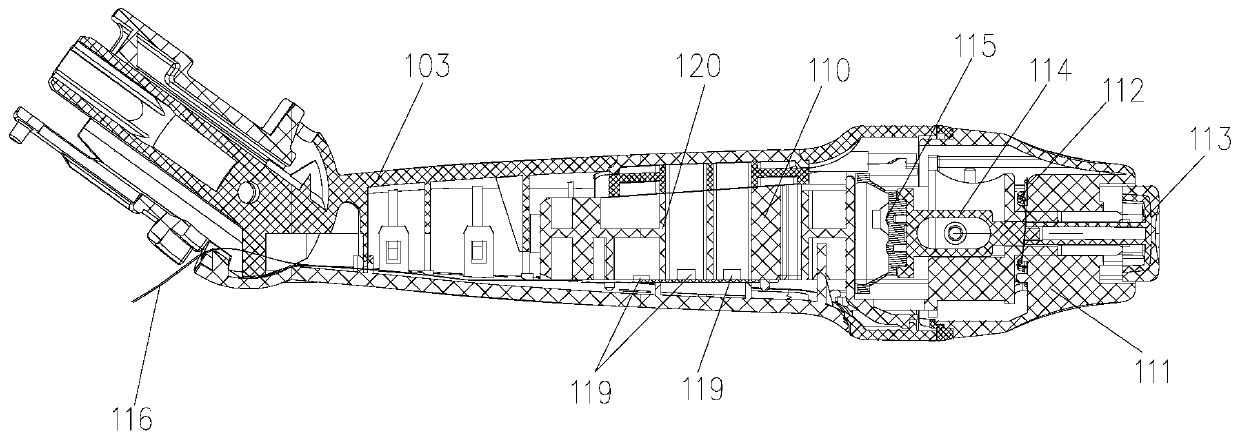

[0018] Examples such as Figures 1 to 6 As shown, an automobile shift handle combination switch assembly includes a handle assembly 1 arranged under the steering wheel, the handle assembly 1 includes a housing 101 fixedly installed under the steering wheel, and the upper and lower ends of the housing 101 are respectively arranged There is an upper cover 123 and a rear cover 124 to realize the airtightness of the housing. The housing 101 is provided with a PCB board 102 electrically connected to the vehicle controller 2, and the housing 101 is also provided with a handle housing 103 that can be moved up and down. One end of the handle housing 103 is sleeved with a dial The fork 105 is provided with a movable contact assembly 104 matched with the PCB board 102 , the fork 105 is provided with a rotating pin 106 , and the rotating pin 106 is rotatably mounted on the housing 101 . The shift fork 105 is driven to rotate by turning the handle housing 103, so that the movable contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com