Micro-LED chip, preparation method thereof and display device

A chip and light-emitting chip technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of unable to drive the backplane welding, etc., and achieve the effect of improving contact performance, avoiding falling off, and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Usually, when preparing a Micro-LED chip, due to the incompatibility of the process flow, it is necessary to separately prepare the light-emitting chip and the driving backplane included in the Micro-LED chip. After the light-emitting chip and the driving backplane are prepared, the electrodes of the light-emitting chip and the electrodes of the driving backplane can be connected to drive the light-emitting chip to emit light.

[0041] In the prior art, the electrodes of the light-emitting chip and the electrodes of the driving backplane are usually welded by a flip-chip welding process.

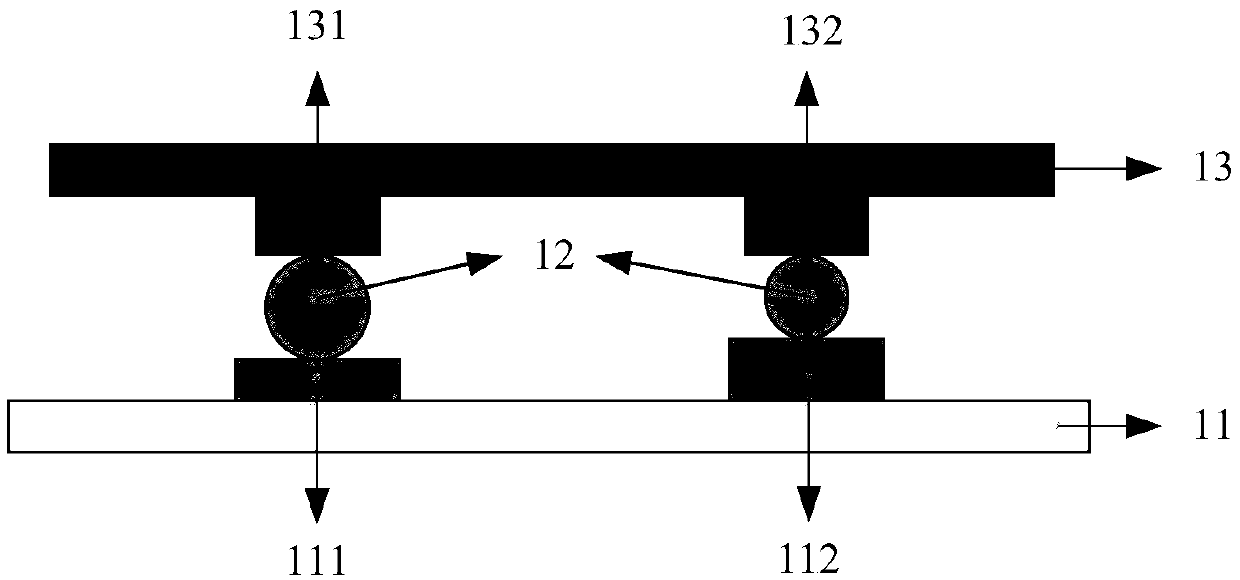

[0042] Specifically, such as figure 1 As shown, first, the solder 12 can be prepared on the electrodes 111 and 112 of the driving backplane 11; secondly, the light-emitting chip 13 is flipped, and the electrodes 131 and 132 of the light-emitting chip 13 are respectively connected to the electrodes 111 of the driving backplane 11. Align with the electrodes 112 ; finally, perform weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com