Flat wire twisting device for armature winding end part of flat wire motor

A technology of armature winding and flat wire is applied in the field of flat wire twisting device at the end of armature winding of flat wire motor. , The effect of saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

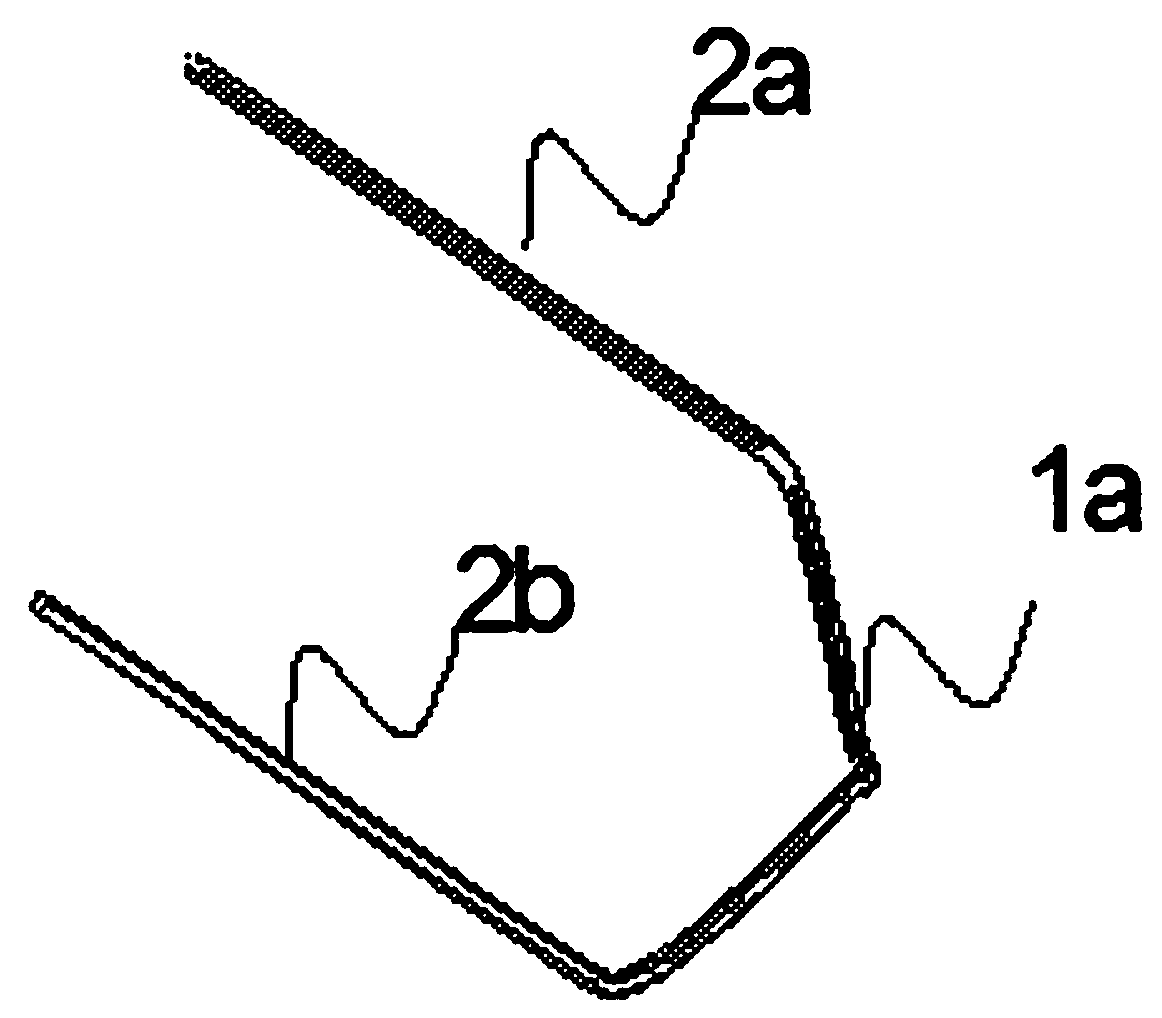

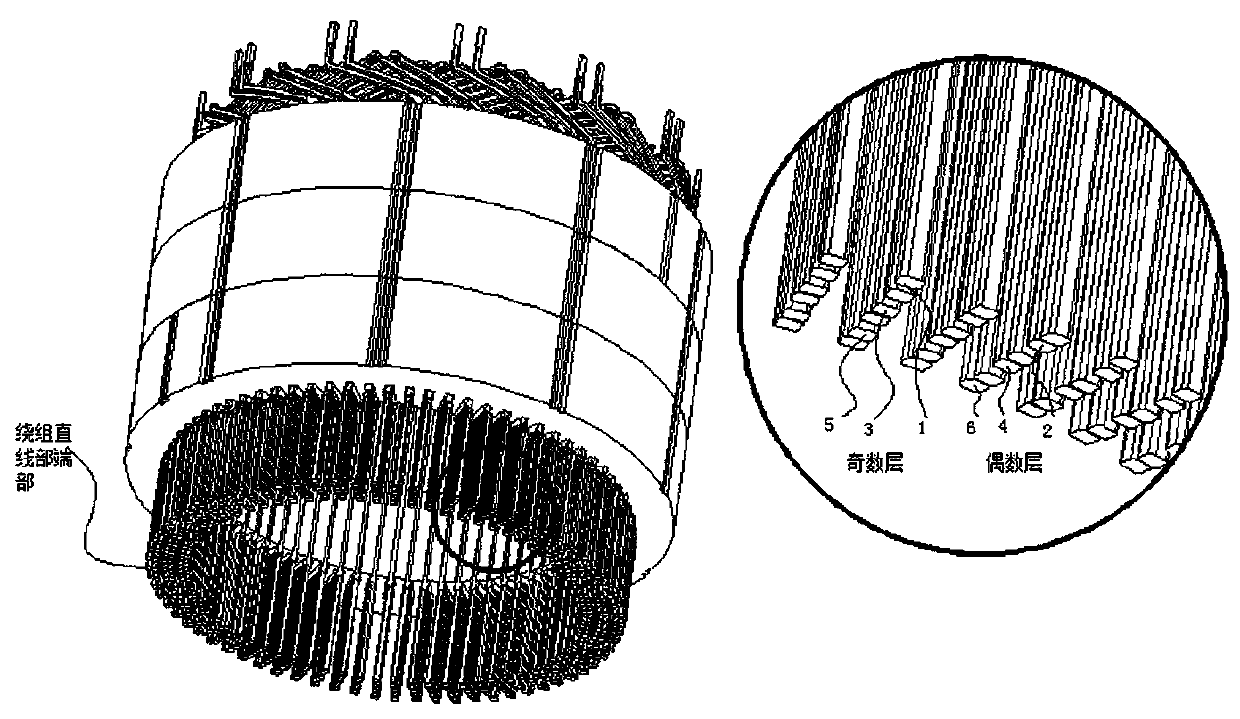

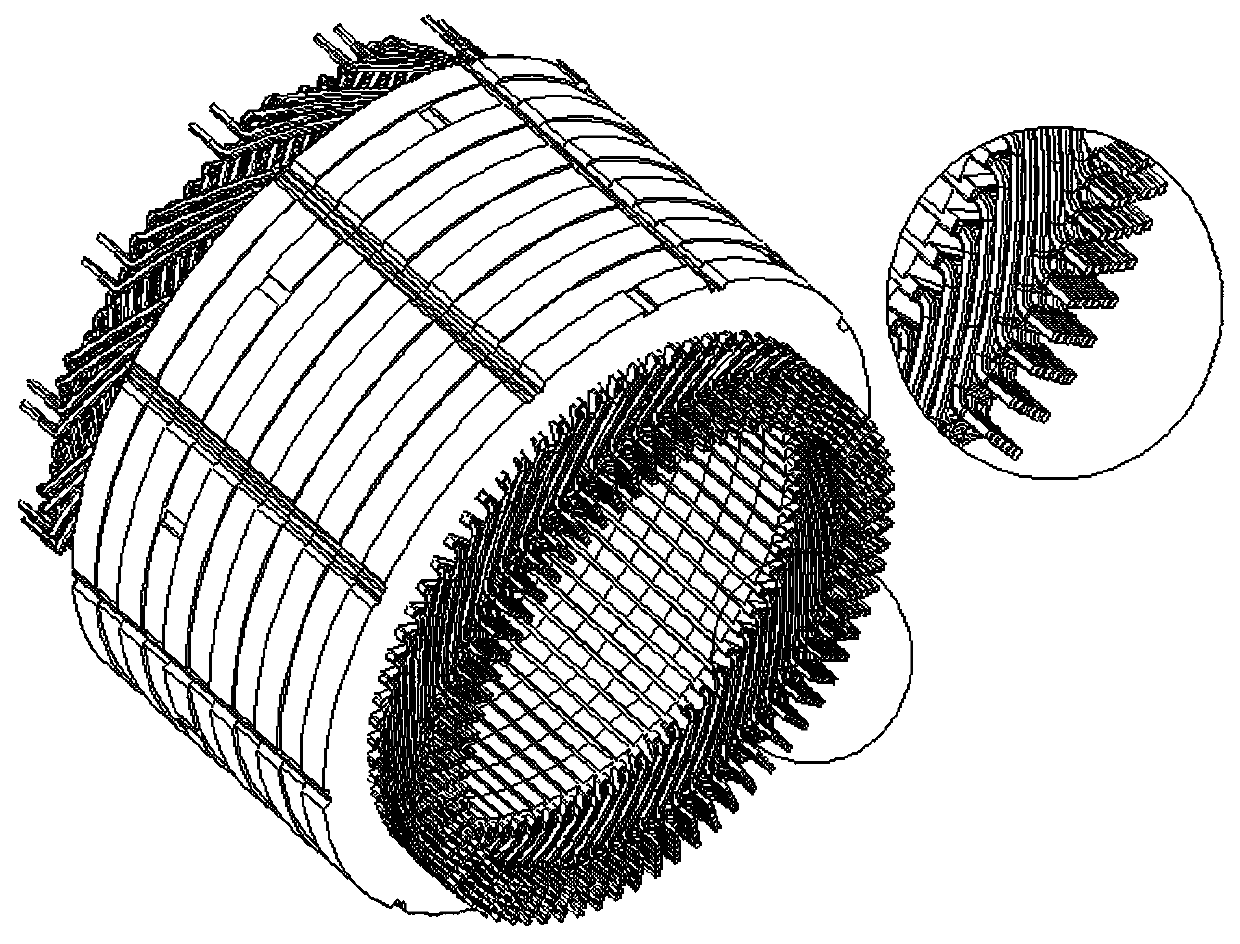

[0031] Such as Figure 4-7 As shown, a twisting device for forming the end of the armature winding of a flat wire motor is used for twisting the flat enameled wire at the end of the armature winding of a flat wire motor during the forming process of the end of the armature winding of a flat wire motor. It includes an ejection mechanism, a twisting mechanism, a power mechanism, and an upper support plate 4 and a lower support plate 5 that are oppositely arranged.

[0032] The ejection mechanism includes an ejection rod 11 , a cylinder 12 and an ejection disc 13 . One end of the ejector rod 11 is connected to the cylinder 12, and the ejector disc 13 is coaxially arranged at the other end of the ejector rod. Cylinder 12 is fixed on lower support plate 5, and ejector rod 11 stretches out upper support plate 4.

[0033] The twisting mechanism is installed between the upper and lower support plates. It includes a plurality of first gears 21 arranged up and down along the same cir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap