A tape laying head and tape laying method suitable for automatic laying and forming of composite materials with variable trajectory

A composite material and track technology, which is applied in the field of tape laying heads, can solve the problems of insufficient reliability of mechanical interlocking, and achieve the effect of automatic conformal laying, high reliability, and avoidance of redundant structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

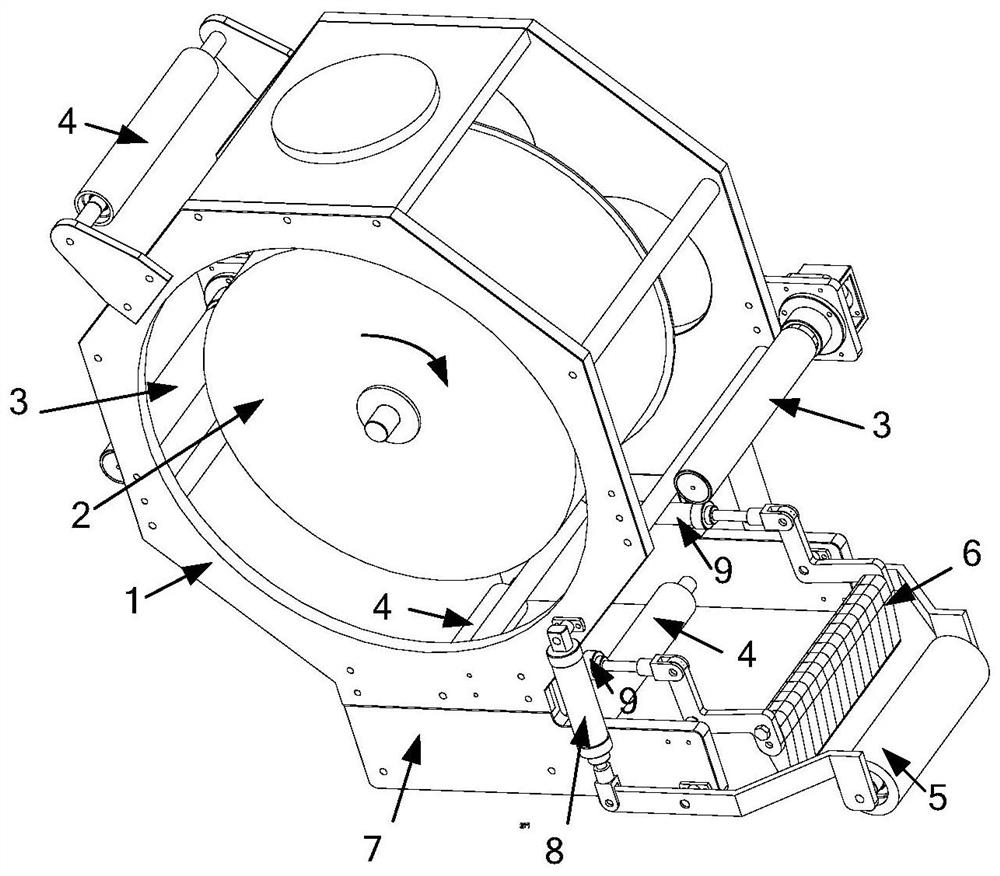

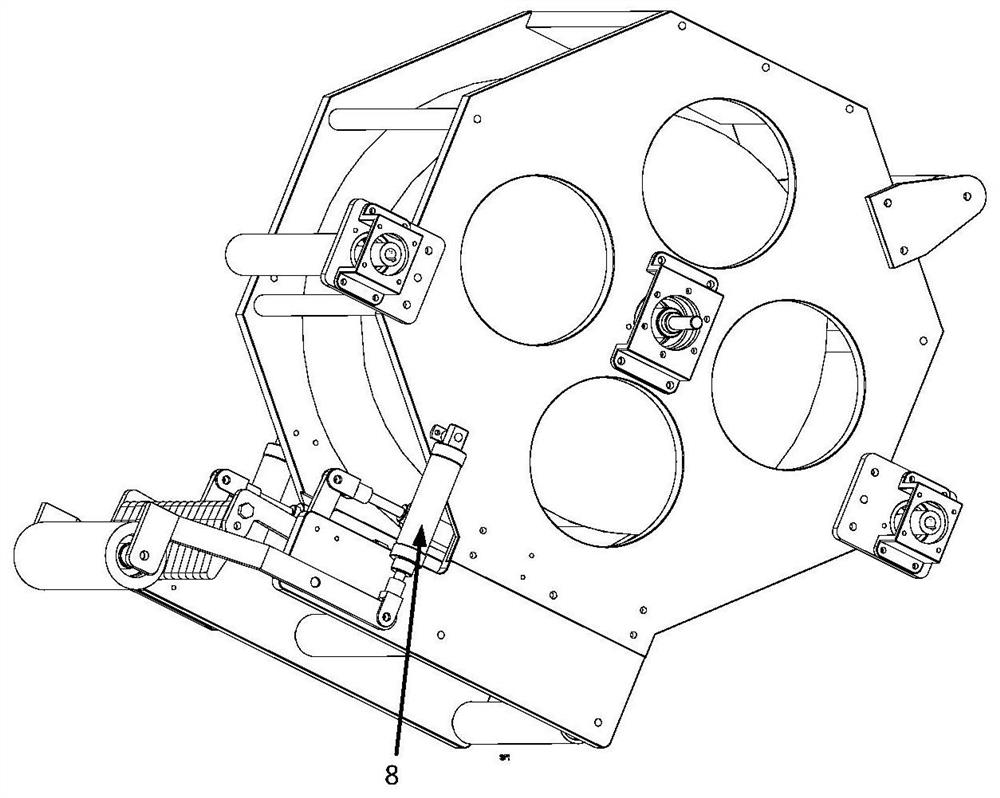

[0035] Such as figure 1 and figure 2 As shown, a tape laying head adapted to the automatic laying and forming of composite materials with variable trajectory, the tape laying head includes a bracket 1, a material roll 2, a power roller 3, a guide roller 4, a terminal roller 5, a pressure shoe 6, a base 7, a first The cylinder 8 and the second cylinder 9; the material of the bracket is stainless steel, the material of the roll is stainless steel, the power roller is 2, the guide roller is 2, the material of the terminal roller is fluorine four, the material of the pressure shoe is fluorine four, the base The material is stainless steel, and the first cylinder and the second cylinder are driven by motors.

[0036] The bracket 1 is fixedly installed on the base 7;

[0037] The material roll 2 has a motor, and the material roll 2 is fixedly installed in the cavity of the support 1 through the rotating shaft of the motor, and the material roll 2 can rotate around the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com